Silicon carbide nano tube as well as preparation method and application thereof

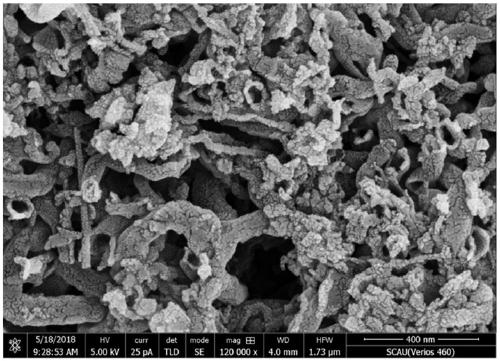

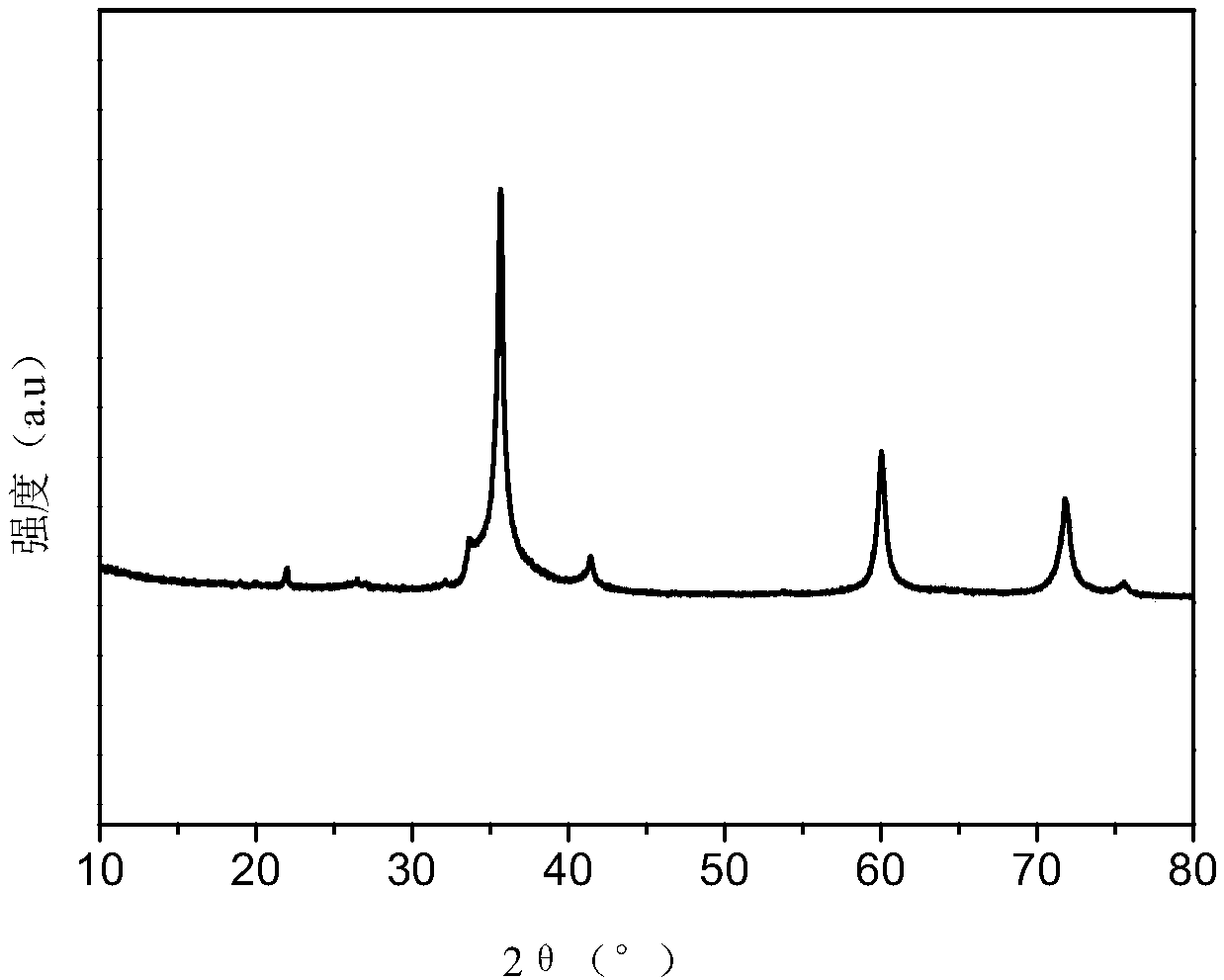

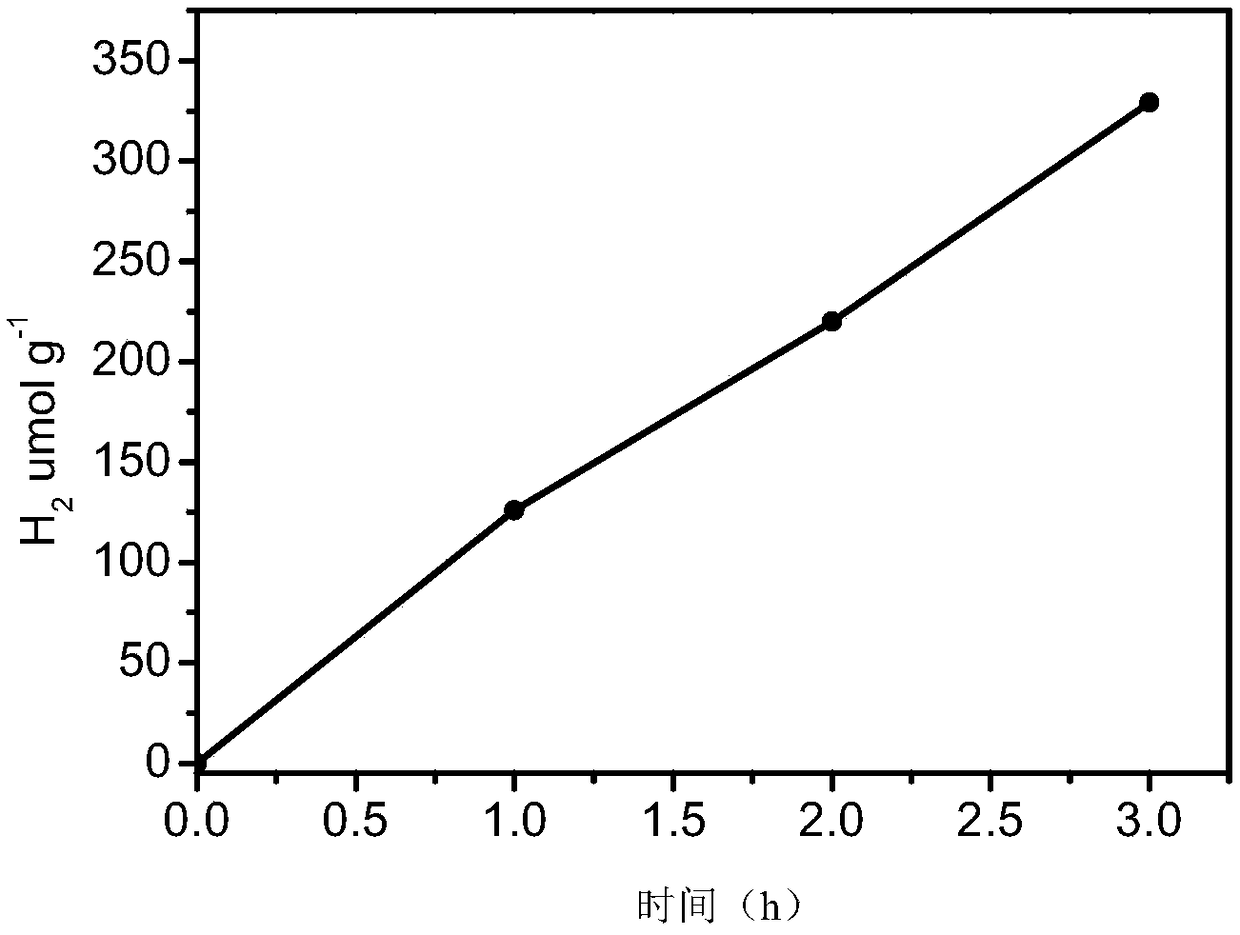

A technology of silicon carbide nanotubes and carbon nanotubes, applied in chemical instruments and methods, nanotechnology, carbon compounds, etc., to achieve stable performance, good repeatability, and unique appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a SiC nanotube material in this embodiment, the specific preparation steps are as follows:

[0041] Carbon nanotube pretreatment: disperse 2.0g carbon nanotubes in the mixed acid of 40ml concentrated nitric acid (68wt%) and 120ml concentrated sulfuric acid (98wt%), sonicate under 300W power for 1 hour, then stir at room temperature for 5 hours, centrifuge , washed three times with deionized water, and dried for later use.

[0042] SiC nanotube material preparation (V-S reaction mechanism): Grind 2.0g of silicon powder and 0.4g of treated carbon nanotubes evenly, put them into a porcelain boat, place the porcelain boat in a tube furnace, and then pass argon protection, Keep the argon flow rate at 250ml / min, raise the temperature to 1350°C at 3°C per minute, keep the temperature for 4 hours, cool down to room temperature naturally, take out the sample, and use an excessive amount of hydrofluoric acid / nitric acid mixed acid (25 ml of hydrofluoric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com