Plasma catalyzing process of preparing hydrogen by ammonia decomposition

A plasma and ammonia decomposition technology, applied in chemical instruments and methods, hydrogen production, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low activity, reduce decomposition temperature and improve performance , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

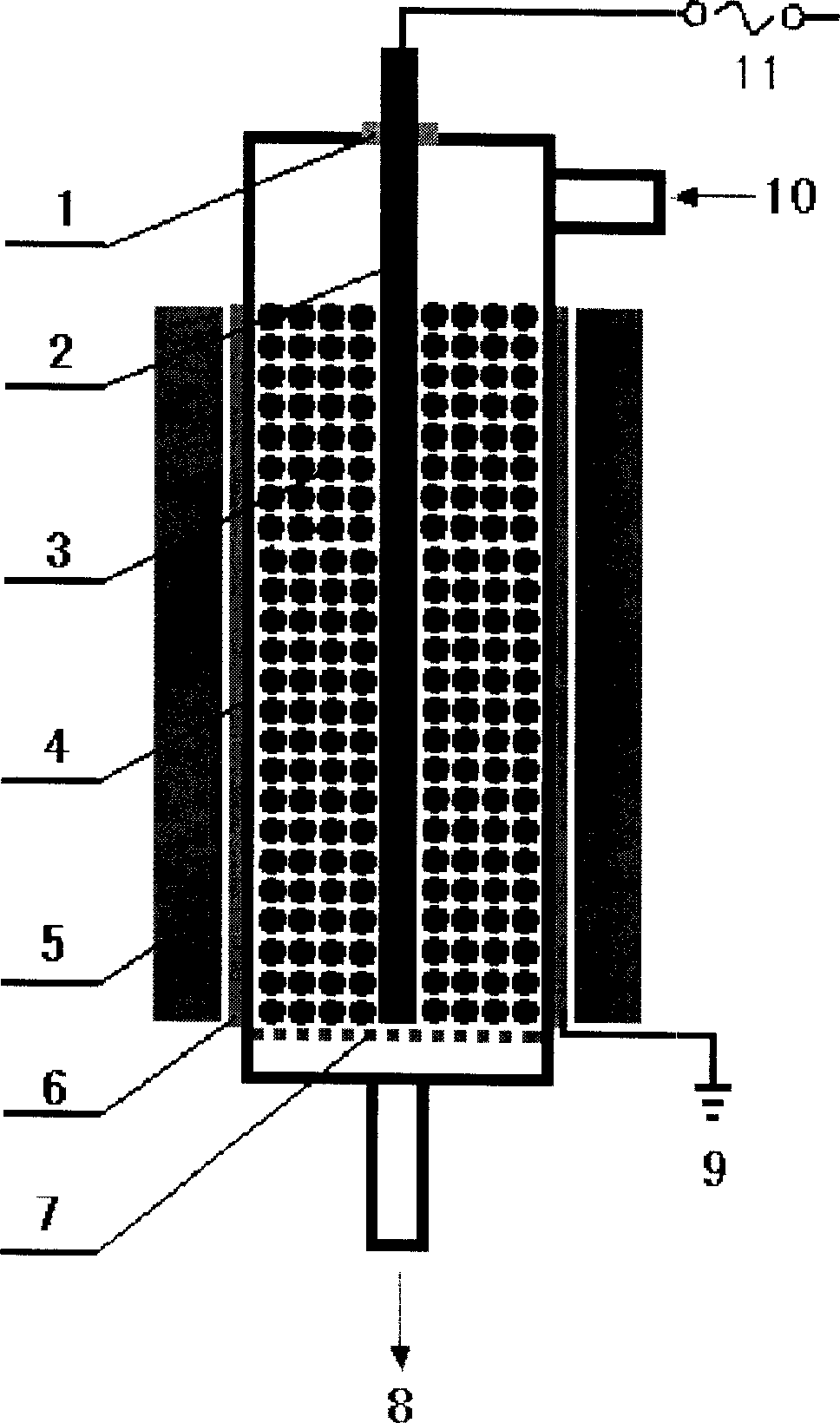

[0046] 6 milliliters of the non-precious metal iron catalyst (expressed as Fe / Al 2 o 3 ) is filled in the discharge area of the wire barrel type dielectric barrier discharge plasma reactor, the catalyst particles are irregular in shape, and the equivalent diameter is 1-1.5 mm, wherein the active ingredient loading in terms of elemental iron (Fe) is 10% ( Weight), the rest is alumina carrier, the ratio of catalyst equivalent diameter to reactor inner diameter is 0.1-0.17. The reactor shell 4 (blocking medium) is made of hard glass, with a wall thickness of 1 mm, an inner diameter of 9 mm, and a discharge zone length of 100 mm. The heat insulation material 5 outside the shell adopts asbestos. The metal high-voltage discharge electrode 2 of the reactor is made of ordinary stainless steel wire with a diameter of 2 mm, and the insulating seal between it and the reactor shell is made of alumina ceramic material. The metal grounding electrode 6 is a copper mesh, and the ceramic s...

Embodiment 2

[0048] Example 1 was repeated, but the discharge parameters were set as follows: the initial voltage of the transformer was 23 volts, and the discharge frequency was 12 kHz. Then the power of the high-voltage power supply reaches 35.19 watts, the actual discharge voltage is 12.33 kV, the temperature of the reactor is stabilized at 363°C after the reaction is stable, and the ammonia decomposition conversion rate reaches 21%.

Embodiment 3

[0050] Example 1 was repeated, but the discharge parameters were set as follows: the initial voltage of the transformer was 27 volts, and the discharge frequency was 12 kHz. Then the power of the high-voltage power supply reaches 41 watts, the actual discharge voltage is 12.1 kV, the temperature of the reactor is stabilized at 371°C after the reaction is stable, and the ammonia decomposition conversion rate reaches 36%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com