Method for manufacturing rare earth extended fibre-optical prefabricated bar

An optical fiber preform, rare earth-doped technology, applied in manufacturing tools, glass manufacturing equipment, optics, etc., can solve the problem of low gain flatness, very limited control of doping uniformity and doping concentration, and uniformity restrictions. and other problems, to achieve the effect of improving the utilization rate of raw materials, improving the indicators of optical devices, and improving the uniformity of doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

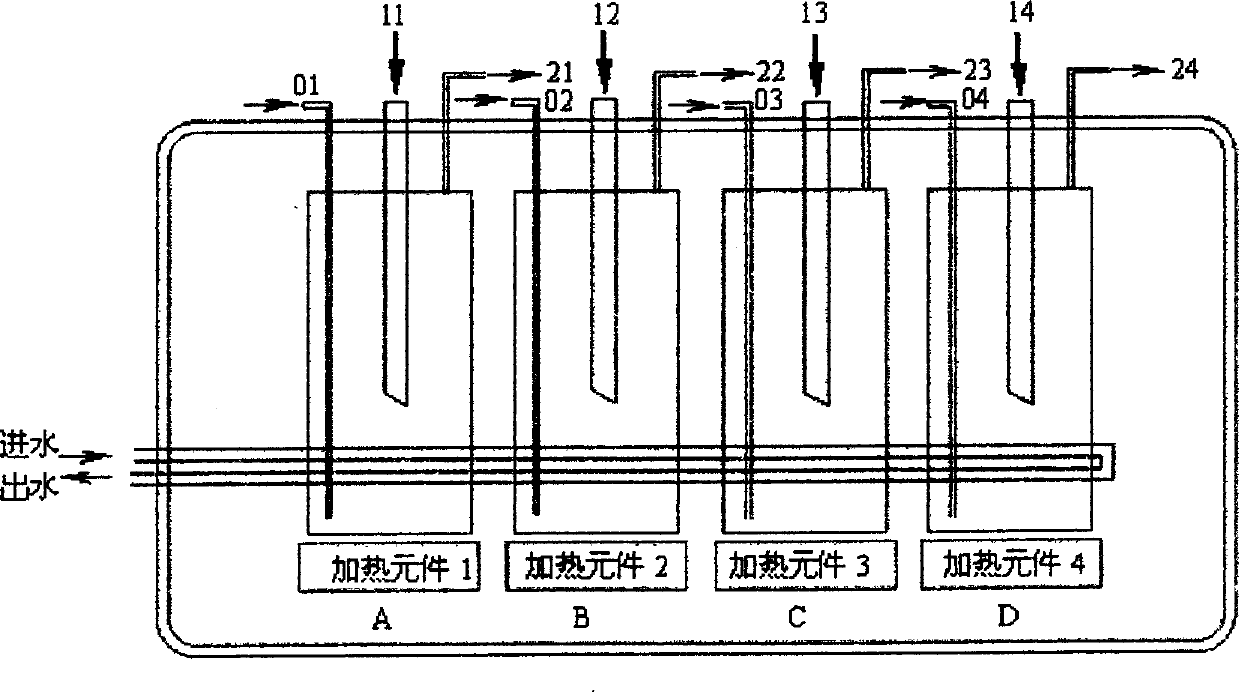

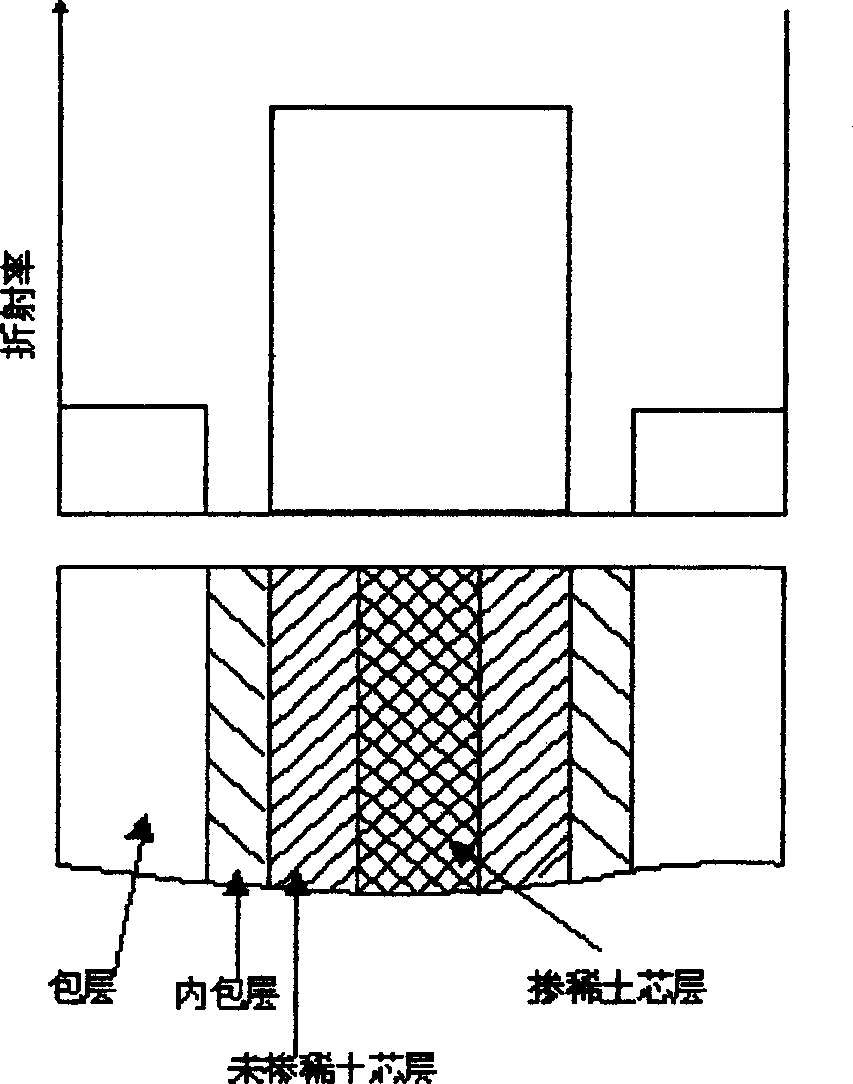

[0029] In the quartz glass tube, silicon tetrachloride, oxygen and dopant sulfur hexafluoride (SF 6 ) for deposition to form an inner cladding layer, and then pass through silicon tetrachloride, germanium tetrachloride, oxygen and dopant sulfur hexafluoride (SF 6 ), phosphorus oxychloride (POCl 3 ) deposition to form the core layer (1), and then silicon tetrachloride, germanium tetrachloride, rare earth compound Yb 2 o 3 and the co-dopant AlCl 3 Use an evaporator to evaporate and mix with oxygen evenly, and finally pass it into a quartz glass tube to deposit a rare earth-doped core layer (2), and use a flow meter to control the flow of various gases, the rare earth compound Yb 2 o 3 The evaporation temperature is 200 °C, the co-dopant AlCl 3 The evaporation temperature is 200°C; after the deposition is completed, the deposition tube is melted and shrunk into a solid preform rod on the shrink rod equipment.

Embodiment 2

[0031] In the quartz glass tube, silicon tetrachloride, oxygen and dopant sulfur hexafluoride (SF 6 ), phosphorus oxychloride (POCl 3 ) for deposition to form an inner cladding, and then pass through silicon tetrachloride, germanium tetrachloride, oxygen and sulfur hexafluoride (SF 6 ), phosphorus oxychloride (POCl 3 ) is deposited to form a core layer (1), and then silicon tetrachloride, germanium tetrachloride, ErCl 3 Rare earth compounds and POCl 3 The co-dopant is evaporated by an evaporator and mixed evenly with oxygen, and the flow of various gases is controlled by a flow meter. The rare earth compound ErCl 3 The evaporation temperature is 300 °C, the co-dopant POCl 3 The evaporation temperature is 300°C; finally, it is deposited in a quartz glass tube, and the deposition temperature is lowered to 1500°C to form a rare earth-doped core layer, and ErCl 3 The above-mentioned core layer is soaked and dried by the rare earth compound solution to form the core layer (2)....

Embodiment 3

[0033] Silicon tetrachloride, oxygen and dopant carbon hexafluoride (C 2 f 6 ) is deposited to form an inner cladding layer, and then silicon tetrachloride, germanium tetrachloride, oxygen and dopant carbon hexafluoride (C 2 f 6 ), phosphorus oxychloride (POCl 3 ) is deposited to form the core layer (1), and then silicon tetrachloride, germanium tetrachloride, rare earth compound TmBr 3 and the co-dopant POCl 3 , AlCl 3 Use an evaporator to evaporate and mix with oxygen evenly, and finally pass it into a quartz glass tube to deposit a rare earth-doped core layer (2), and use a flow meter to control the flow of various gases. The rare earth compound TmBr 3 The evaporation temperature is 200 °C, the co-dopant POCl 3 , AlCl 3 The evaporation temperature is 200°C; after the deposition is completed, the deposition tube is melted and shrunk into a solid preform rod on the shrink rod equipment.

[0034] The rare earth compound in the above embodiment can be: a halide or an ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com