A kind of preparation method of nickel-zinc ferrite nanometer material doped with cobalt

A technology of nickel-zinc ferrite and nanomaterials, applied in the fields of magnetic materials, nanotechnology, inorganic material magnetism, etc., can solve the problems of disadvantage, poor wave absorbing performance, high production cost of ferrite wave absorbing materials, and achieve defects. less, less agglomeration, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

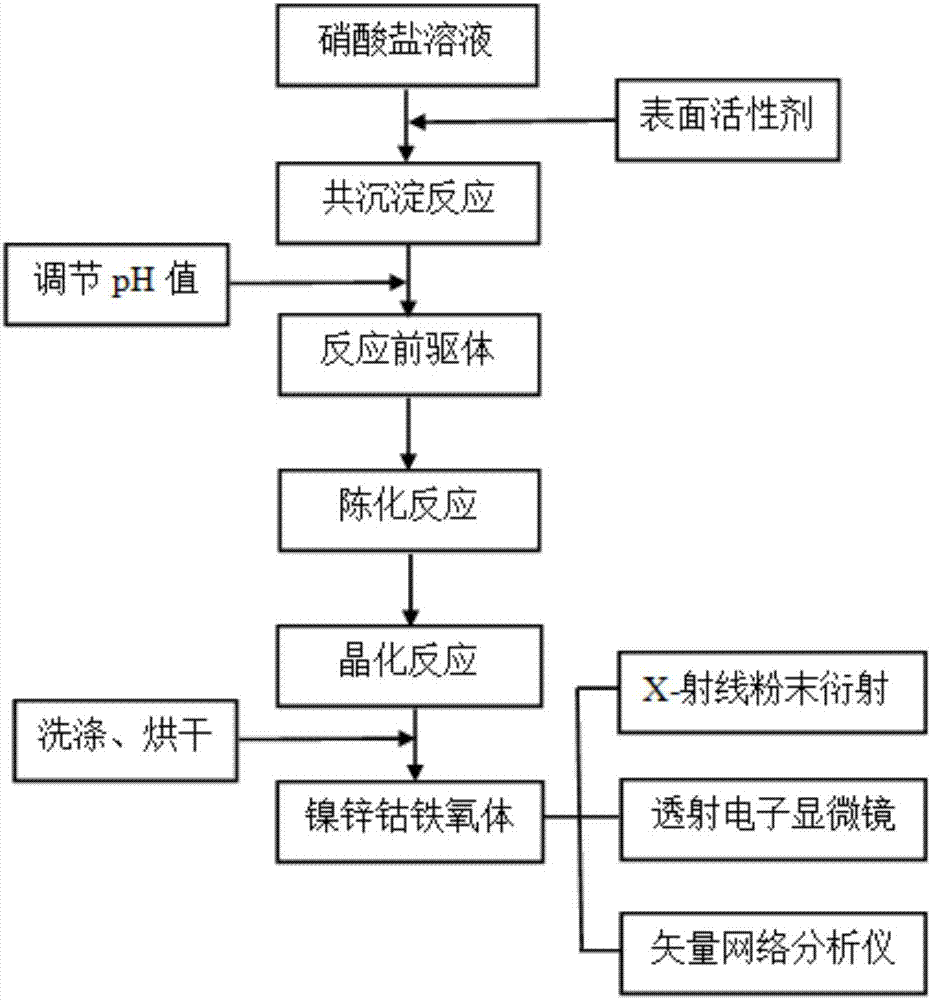

[0043] A preparation method of cobalt-doped nickel-zinc ferrite nanomaterials, comprising the following steps:

[0044] Step 1, Ingredients:

[0045] (1) Press Ni 0.5 Zn 0.4 co 0.1 Fe 2 o 4 Stoichiometric ratio, take 4 kinds of raw materials respectively: 3.64g analytical pure nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O), 2.97g analytically pure zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O), 0.73g analytically pure cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) and 20.20g of analytically pure ferric nitrate (Fe(NO 3 ) 3 9H 2 O);

[0046] (2) Dissolve the above 4 kinds of raw materials in 150mL distilled water, add 2g of polyethylene glycol, and perform ultrasonic treatment to disperse them evenly to obtain a reddish-brown mixed solution;

[0047] Step 2: generate reaction precursor;

[0048] Put the reddish-brown mixed solution in a four-necked flask, and stir continuously and uniformly at a constant temperature water bath of 30°C at a speed of 210r / min; at the same time, add 3mol / L sodium...

Embodiment 2

[0061] A preparation method of cobalt-doped nickel-zinc ferrite nanomaterials, comprising the following steps:

[0062] Step 1, Ingredients:

[0063] (1) Press Ni 0.6 Zn 0.15 co 0.25 Fe 2 o 4 Stoichiometric ratio, take 4 kinds of raw materials respectively: 4.36g analytical pure nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O), 1.12g analytically pure zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O), 1.82g analytically pure cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) and 20.20g of analytically pure ferric nitrate (Fe(NO 3 ) 3 9H 2 O);

[0064] (2) Dissolve the above 4 kinds of raw materials in 150mL distilled water, add 2g of polyethylene glycol, and perform ultrasonic treatment to disperse them evenly to obtain a reddish-brown mixed solution;

[0065] Step 2: generate reaction precursor;

[0066] Put the reddish-brown mixed solution in a four-necked flask, and stir continuously and uniformly at a constant temperature water bath of 40°C at a speed of 180r / min; at the same time, add 2mol / L so...

Embodiment 3

[0079] A preparation method of cobalt-doped nickel-zinc ferrite nanomaterials, comprising the following steps:

[0080] Step 1, Ingredients:

[0081] (1) Press Ni 0.4 Zn 0.4 co 0.2 Fe 2 o 4 Stoichiometric ratio, take 4 kinds of raw materials respectively: 2.91g analytical pure nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O), 2.97g analytically pure zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O), 1.46g analytically pure cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) and 20.20g of analytically pure ferric nitrate (Fe(NO 3 ) 3 9H 2 O);

[0082] (2) Dissolve the above 4 kinds of raw materials in 150mL distilled water, add 2g of polyethylene glycol, and perform ultrasonic treatment to disperse them evenly to obtain a reddish-brown mixed solution;

[0083] Step 2: generate reaction precursor;

[0084] Put the reddish-brown mixed solution in a four-necked flask, and stir continuously and uniformly at a constant temperature water bath of 45°C at a speed of 150r / min; at the same time, drop 1.5mol / L s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com