A kind of composite oxide electrode material and preparation method thereof

A composite oxide, electrode material technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of electrode processing performance to be improved, uneven particle size of solid-phase materials, inability to achieve technical performance, etc., and achieve spherical particle size. Adjustable distribution, good multi-level distribution, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Formula composite positive electrode material of the present embodiment is Li 1.2 Ni 0.13 CO 0.13 Mn 0.54 O 2 (0.5LiNi 1 / 3 CO 1 / 3 Mn 1 / 3 O 2 · 0.5Li 2 Mno 3 ), Was prepared following steps:

[0036] Molar ratio of Ni: Co: Mn = 0.13: 0.13: 0.54 was weighed nickel oxalate, cobalt oxalate, manganese oxalate, ball mill jar was added with stirring, a certain amount of deionized water was added, the solid content of the slurry is 30%, stirring ball mill 1h. And a molar ratio of Li: (Ni + Co + Mn) = 1.5, lithium hydroxide were weighed and slowly added to the slurry, stirring was continued for milling 5h, to obtain a semi-solid phase slurry.

[0037] The slurry was aged for 12h, and then dried by a spray drier, the powder was collected and dried. The dried powder was placed in a muffle furnace, 900 ℃ calcined 12h. After cooling to obtain a desired material.

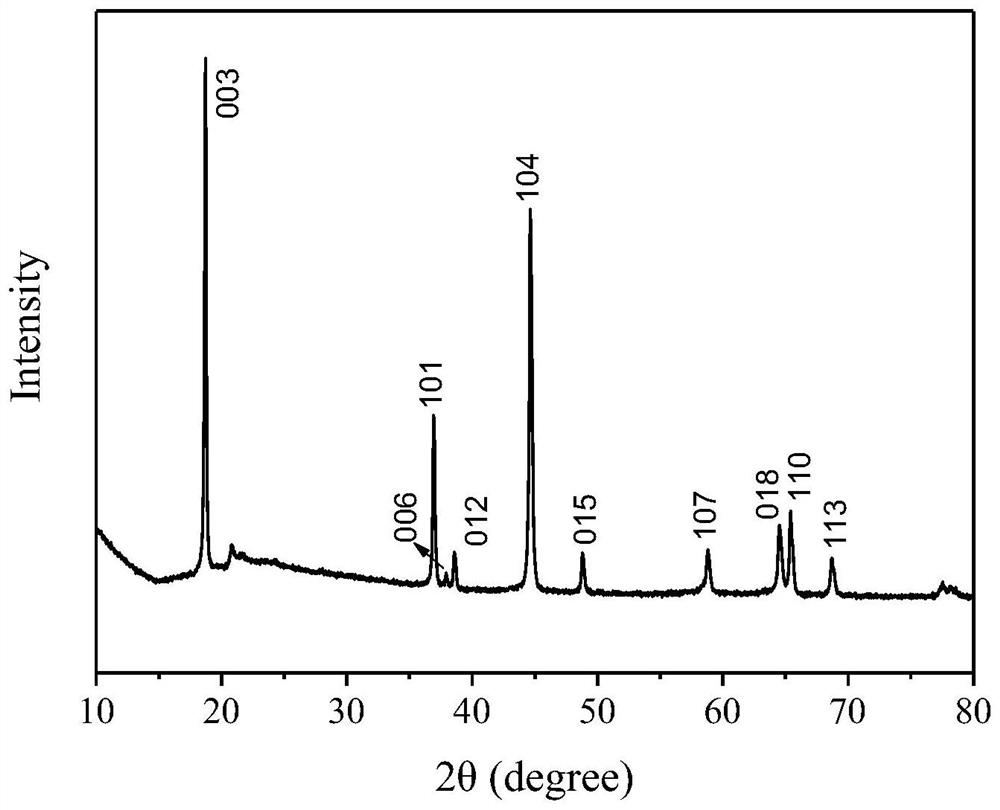

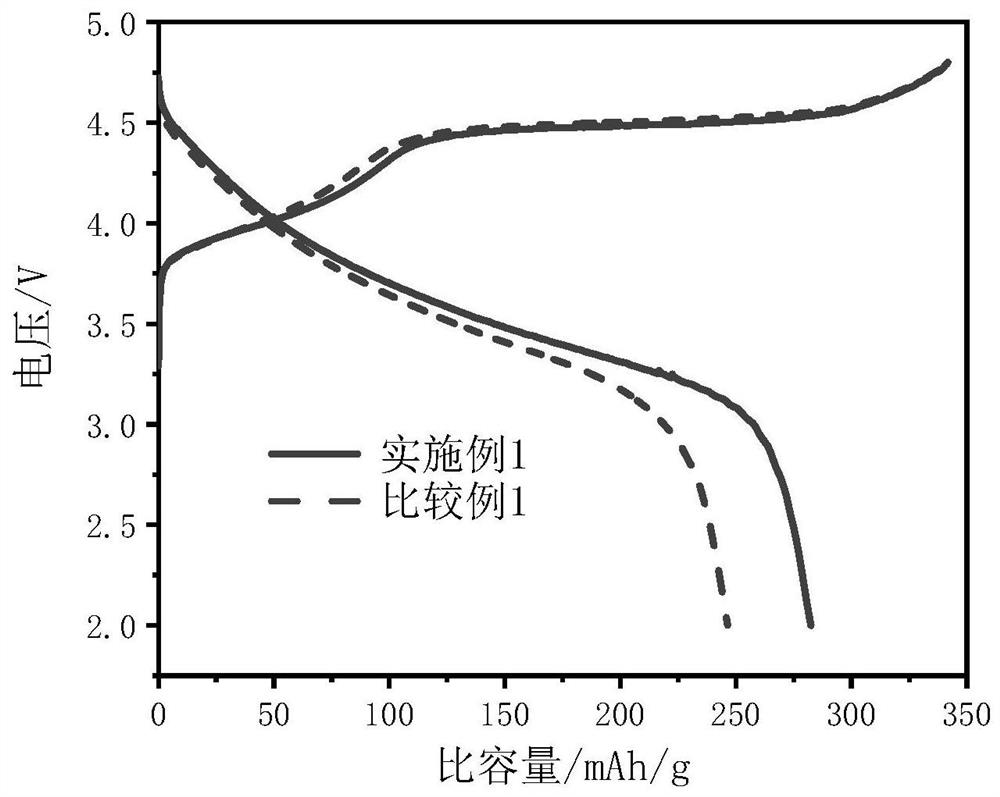

[0038] To test whether the material for our present target material, the material is a powder X-ray diffraction test resul...

Embodiment 2

[0044] Formula composite positive electrode material of the present embodiment is LiNi 0.5 CO 0.2 Mn 0.3 O 2 Preparation steps are as follows:

[0045] Said nickel-stoichiometric taking nitrate, cobalt nitrate, manganese acetate, ball mill jar was added, a certain amount of N- methylpyrrolidone, milling 1h. Stoichiometric lithium oxide was then added, continue milling 5h.

[0046] The precursor slurry is aged for 15H, and then dried by a spray dryer, the dried powder was placed in a muffle furnace, calcining deg.] C 15H 850, into the air during firing. After cooling to obtain the desired product.

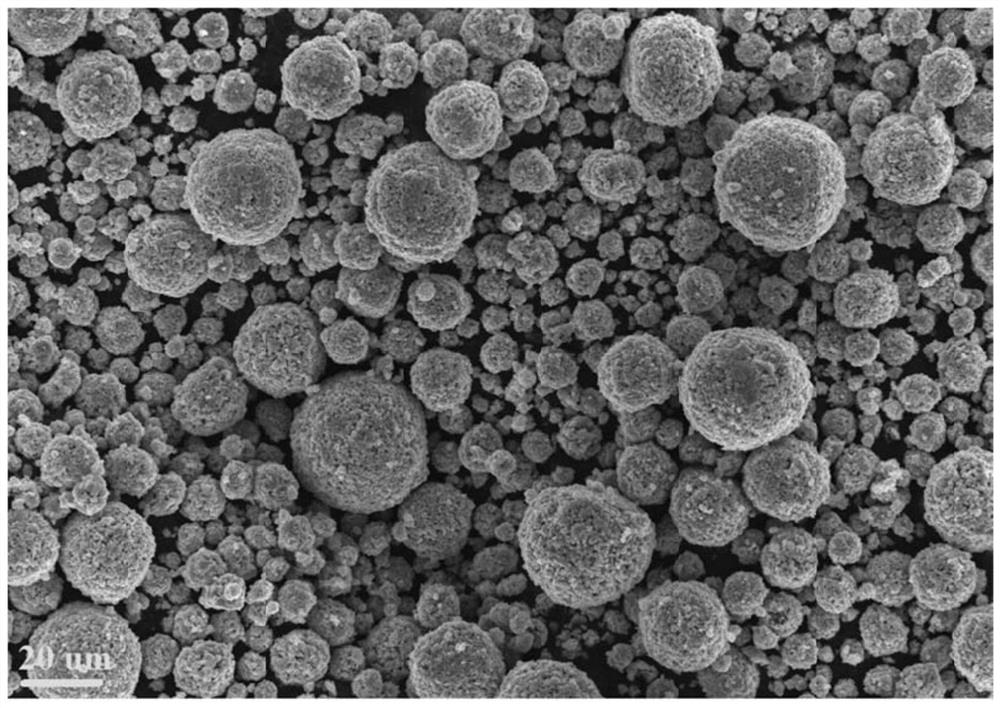

[0047] The material under a scanning electron microscope image, such as image 3 , The particles are spherical, particle size range of about 3-30um, such a large ball and the ball multistage mixing spherical particles have higher tap density. The tap density of the material was 2.71g / cm 3 , Higher than the commercially available positive electrode material LiNi 0.5 CO 0.2 Mn 0.3 O 2 Th...

Embodiment 3

[0050] Formula composite positive electrode material of the present embodiment is LiNi 0.8 CO 0.1 Mn 0.1 O 2 Preparation steps are as follows:

[0051] Stoichiometrically weighed nickel carbonate, cobalt carbonate, manganese oxalate, ball mill jar was added, deionized water, adjusted to a solids content of 25%, milling 1h. Stoichiometric lithium hydroxide was then added, continue milling 5h, to obtain a precursor slurry.

[0052] The precursor slurry is aged for 24h, and then dried by a spray drier, the powder was collected and dried. The dried powder was put into an atmosphere furnace, 750 ℃ calcined 12h, oxygen was calcined. After cooling to obtain the desired product.

[0053] The tap density of the material is 2.8g / cm 3 In the voltage range 2.5-4.3V, 20mA / g current density, discharge capacity of the first week 190.5mAh / g.

[0054] The material is an X-ray energy spectrum as shown in 5, Ni, Co, Mn distribution element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com