Method for preparing N-doped graphene through ion implantation

A technology of nitrogen-doped graphene and ion implantation, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. Poor electrical properties of doped graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of multilayer film samples:

[0062] SiO by magnetron sputtering 2 / Si substrate coated with 40nm a-SiC (amorphous silicon carbide) film (background vacuum 10 - 5 Pa, deposition rate 0.3As -1 );

[0063] Then, on the above-mentioned coated substrate, 100nm Cu and 250nmNi films were sequentially plated on the basis of the a-SiC film by using filtered cathodic vacuum arc deposition (FCVA) (background vacuum 10 -3 Pa, the deposition rate is 0.5As, respectively -1 , 0.2As -1 ).

[0064] Ion Implantation:

[0065] N ion implantation parameters:

[0066] Vacuum (1×10 -3 Pa), energy (40keV), dose 5×10 15 ions cm -2 .

[0067] Rapid annealing:

[0068] The heating rate was 90°C / s, the annealing temperature was 800°C, and the annealing time was 3min, and NG was prepared.

[0069] Test Results:

[0070] N doping amount 0.5at%, electron mobility 800cm 2 V -1 the s -1 .

Embodiment 2

[0072] Preparation of multilayer film samples:

[0073] SiO by magnetron sputtering 2 / Si substrate coated with 20nm a-SiC (amorphous silicon carbide) film (background vacuum 10 - 5 Pa, deposition rate 0.3As -1 );

[0074] Then, on the above-mentioned coated substrate, utilize filter cathodic vacuum arc coating technology (FCVA) to plate 50nm Cu and 200nmNi thin films successively on the basis of a-SiC film (background vacuum 10 -3 Pa, the deposition rate is 0.5As, respectively -1 , 0.2As -1 ).

[0075] Ion Implantation:

[0076] N ion implantation parameters:

[0077] Vacuum (8×10 -4 Pa), energy (40keV), dose 4×10 15 ions cm -2 .

[0078] Rapid annealing:

[0079] The heating rate was 50°C / s, the annealing temperature was 800°C, and the annealing time was 3min, and NG was prepared.

[0080] Test Results:

[0081] N doping amount 0.4at%, electron mobility 850cm 2 V -1 the s -1 .

Embodiment 3

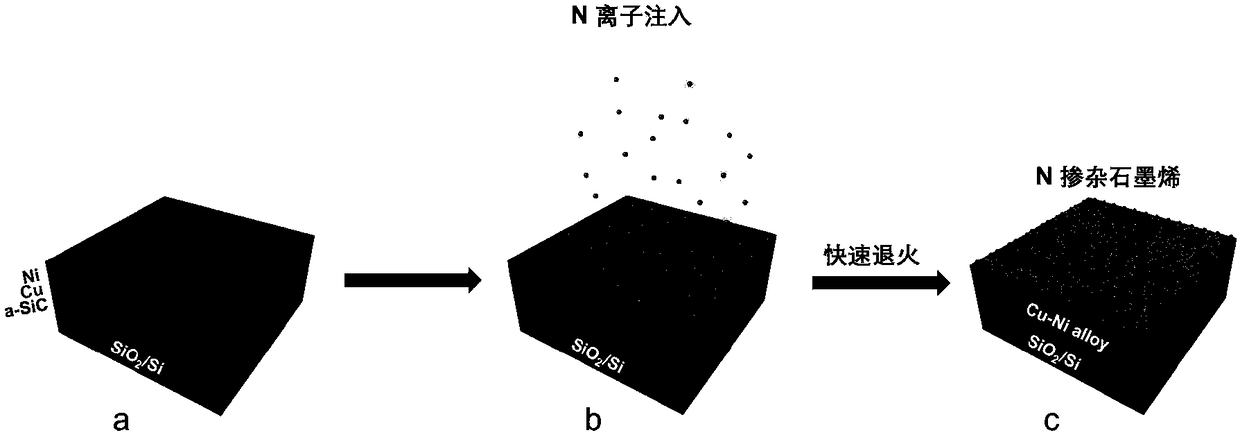

[0083] The preparation process of this embodiment is as follows image 3 As shown, there are three steps:

[0084] Preparation of multilayer film samples:

[0085] SiO by magnetron sputtering 2 / Si substrate coated with 30nm a-SiC (amorphous silicon carbide) film (background vacuum 10 - 5 Pa, deposition rate 0.3As -1 )

[0086] Then, on the above-mentioned coated substrate, utilize filter cathodic vacuum arc coating technology (FCVA) to sequentially plate 100nm Cu and 300nmNi thin films on the basis of a-SiC thin films (background vacuum 10 -3 Pa, the deposition rate is 0.5As, respectively -1 , 0.2As -1 ).

[0087] Ion Implantation:

[0088] N ion implantation parameters:

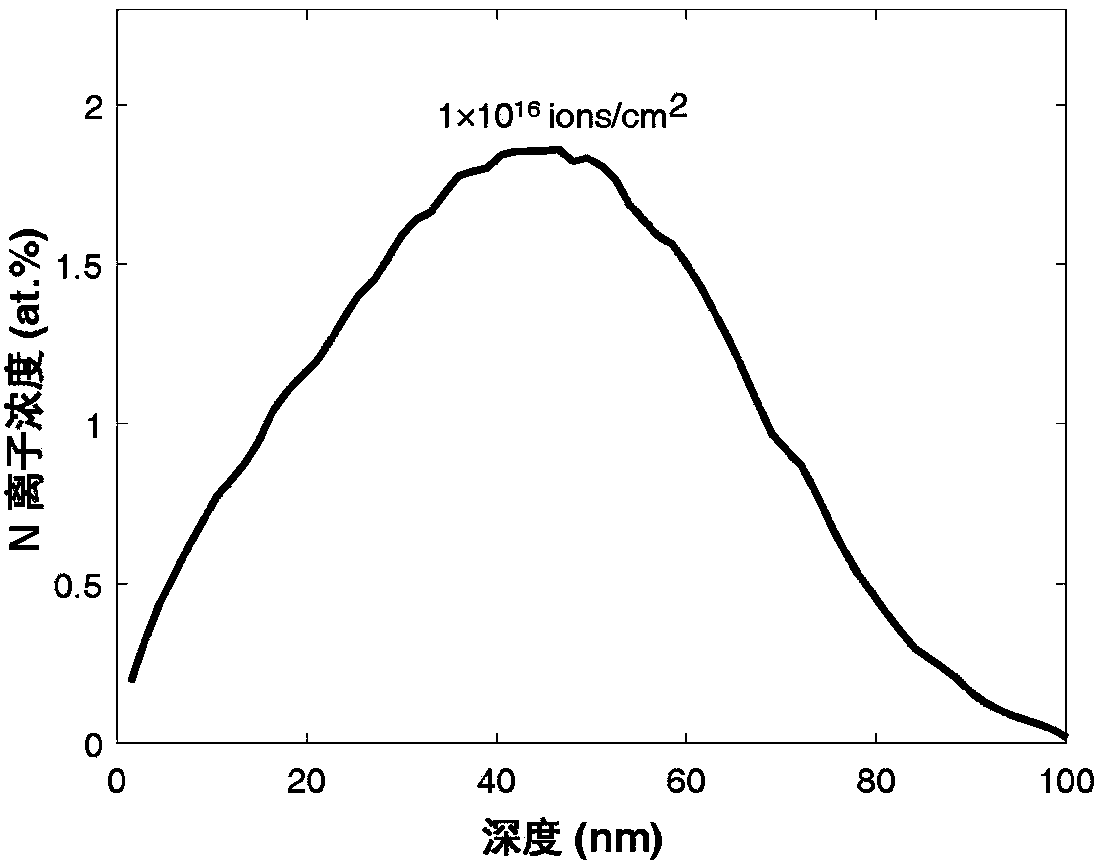

[0089] Vacuum (8×10 -4 Pa), energy (40keV), dose 1×10 16 ions cm -2 .

[0090] Rapid annealing:

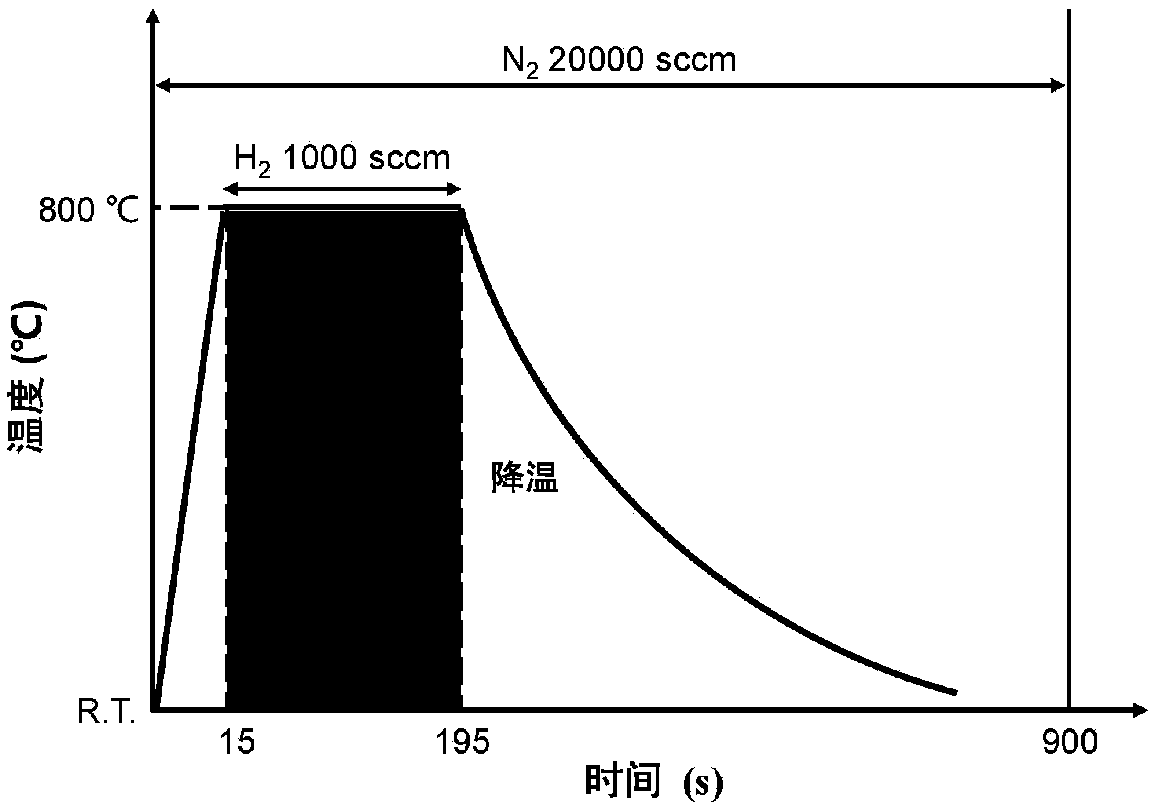

[0091] The annealing process curve is as figure 2 As shown, the heating rate is 70°C / s, the annealing temperature is 800°C, and the annealing time is 3min, and NG is prepared.

[0092] Test Re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com