A kind of photocatalytic self-cleaning environmental protection coating and preparation method thereof

An environmentally friendly coating and self-cleaning technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of human respiratory hazards, soil compaction, water quality, air pollution, etc., and achieve the effects of less investment in equipment, environmentally friendly prices, and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

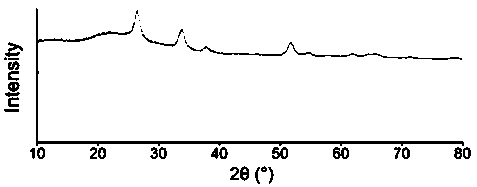

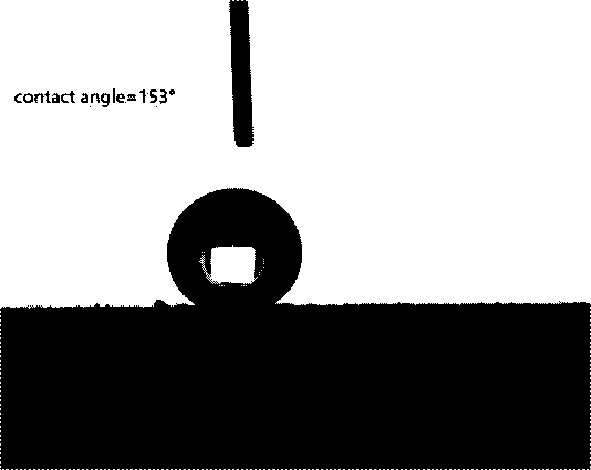

Image

Examples

Embodiment 1

[0033] The preparation method of a kind of photocatalytic self-cleaning environmental protection coating of the present embodiment comprises the following steps:

[0034] (1) Mix 80g waste marble powder, 50g hollow glass microspheres, 30g titanium hydride and 30g sodium peroxide in ethanol and stir for 0.5h.

[0035] (2) Add 10g of tin powder and 10g of antimony iodide in sequence and continue mixing and stirring for 0.5h.

[0036] (3) Put the mixed liquid into the polytetrafluoroethylene lining after soaking in aqua regia for 1 hour and distilling and boiling for 3 times, then place the lining in the matching cylinder and tighten it.

[0037] (4) The whole reaction kettle was placed in a constant temperature reactor and reacted at 150°C for 3 hours.

[0038] (5) After the reaction, all the products were centrifuged at a speed of 6000r / min, and the precipitate was taken, washed with deionized water, and then dried to obtain a powder.

[0039] (6) Take 80g of the final powder...

Embodiment 2

[0052]The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this embodiment, 100g of waste marble powder, 80g of hollow glass microspheres, 50g of titanium hydride and 45g of sodium peroxide were mixed and stirred in ethanol for 1 hour, and then 20 grams of tin powder and 15 grams of antimony iodide were added successively and continued to mix and stir for 1 hour . Put the mixed liquid into the polytetrafluoroethylene liner soaked in aqua regia and distilled and boiled, and then place the secondary liner in the matching cylinder and tighten it. The whole reaction kettle was placed in a constant temperature reactor, and reacted at 250° C. for 7 hours. After the reaction, all the products were centrifuged at a speed of 8000r / min, and the precipitate was collected, washed with deionized water, and then dried to obtain a powder...

Embodiment 3

[0054] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this example, 90g of waste marble powder, 65g of hollow glass microspheres, 40g of titanium hydride and 35g of sodium peroxide were mixed and stirred in ethanol for 0.75h, and then 15g of tin powder and 20g of antimony iodide were added successively to continue mixing Stir for 0.75h. Put the mixed liquid into the polytetrafluoroethylene liner soaked in aqua regia and distilled and boiled, and then place the secondary liner in the matching cylinder and tighten it. The whole reaction kettle was placed in a constant temperature reactor and reacted at 200°C for 5h. After the reaction, all the products were centrifuged at a speed of 6000r / min, and the precipitate was collected, washed with deionized water, and then dried to obtain a powder. Take 90g of final powder an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com