A low-temperature preparation method of carbon nanotubes

A carbon nanotube and low-temperature technology, which is applied in the field of low-temperature preparation of carbon nanotubes, can solve the problem that the growth temperature is difficult to drop to the integrated circuit process, and achieve the effects of low cost, simple preparation process, and process compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A low-temperature preparation method of carbon nanotubes, the steps are as follows

[0029] 1) Dissolve 2.91g nickel nitrate hexahydrate and 2.56g magnesium nitrate hexahydrate in 100mL ethanol to prepare a mixed solution as a catalyst precursor, and make Ni(NO 3 ) 2 and Mg(NO 3 ) 2 The concentration is 0.1mol / L Ni(NO 3 ) 2 / Mg(NO 3 ) 2 mixture;

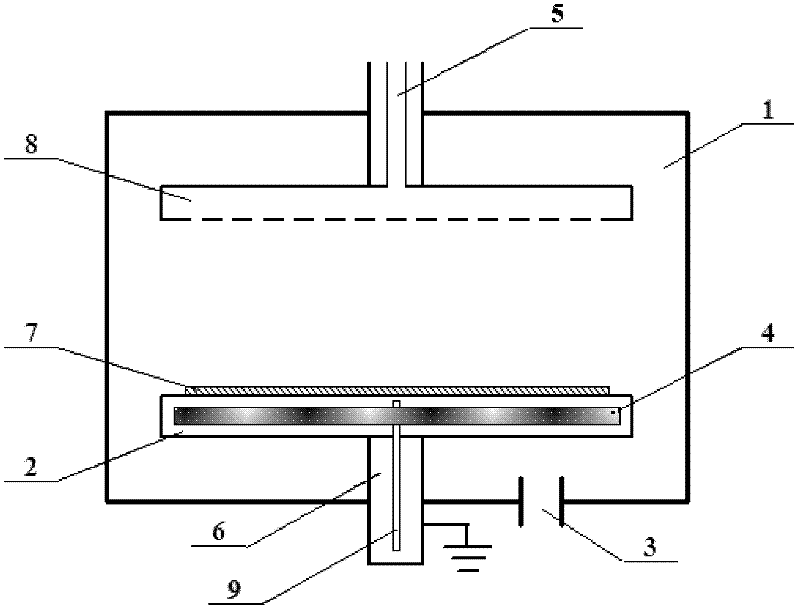

[0030] 2) Spray the above mixed solution evenly on the glass substrate, dry it at 80°C, and place it on the sample stage of the vacuum chamber of the chemical vapor deposition (PECVD) system;

[0031] 3) Close the vacuum chamber, and use a mechanical pump and a Roots pump to evacuate. When the vacuum degree reaches below 0.1Pa, feed hydrogen gas with a flow rate of 40mL / min into the vacuum chamber. When the pressure reaches 300Pa, heat the sample stage to 400℃, Ni(NO 3 ) 2 and Mg(NO 3 ) 2 Decomposes at 400°C and forms NiO and MgO;

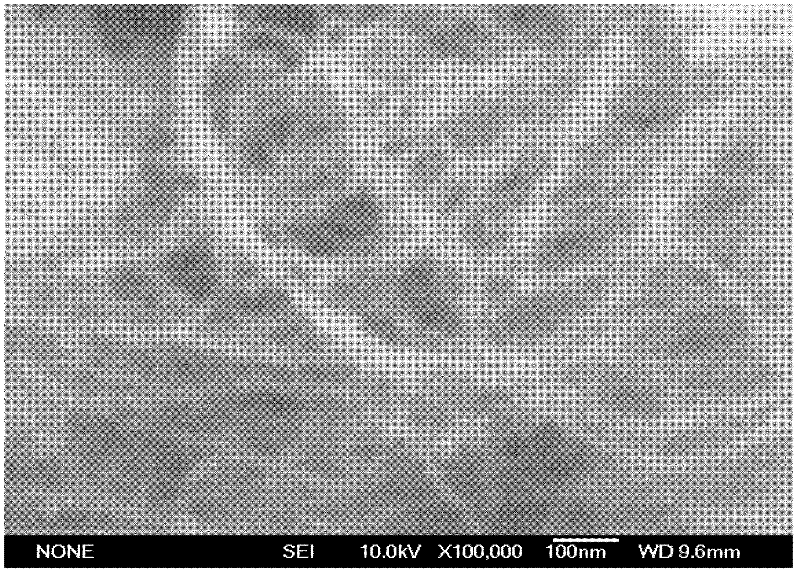

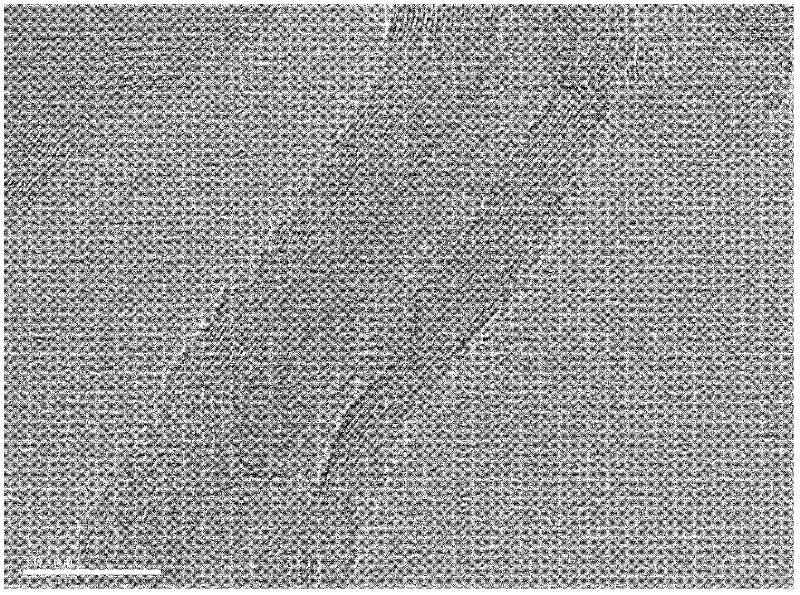

[0032] 4) After 2 hours of decomposition reaction, turn on the radio frequency pow...

Embodiment 2

[0037] A low-temperature preparation method of carbon nanotubes, the steps are as follows

[0038] 1) 2.91g nickel nitrate hexahydrate and 7.68g magnesium nitrate hexahydrate were dissolved in 100mL ethanol to prepare a mixed solution as a catalyst precursor, Ni(NO 3 ) 2 : Mg(NO 3 ) 2 The molar ratio is 1:3, Ni(NO 3 ) 2 The concentration is still 0.1mol / L;

[0039] 2) Spray the above mixed solution evenly on the glass substrate, dry it at 80°C, and place it on the sample stage of the vacuum chamber of the chemical vapor deposition (PECVD) system;

[0040] 3) Close the vacuum chamber, and vacuumize with a mechanical pump and a Roots pump. When the vacuum degree reaches below 0.1Pa, feed hydrogen gas with a flow rate of 30mL / min into the vacuum chamber. When the pressure reaches 300Pa, heat the sample stage to 450℃, Ni(NO 3 ) 2 and Mg(NO 3 ) 2 Decomposes at 450°C and forms NiO and MgO;

[0041] 4) After 2 hours of decomposition reaction, turn on the radio frequency po...

Embodiment 3

[0045] 1) Dissolve 2.91g nickel nitrate hexahydrate and 2.56g magnesium nitrate hexahydrate in 100mL ethanol to prepare a mixed solution as a catalyst precursor, and make Ni(NO 3 ) 2 and Mg(NO 3 ) 2 The concentration is 0.1mol / L Ni(NO 3 ) 2 / Mg(NO 3 ) 2 mixture;

[0046] 2) Spray the above mixed solution evenly on the glass substrate, dry it at 80°C, and place it on the sample stage of the vacuum chamber of the chemical vapor deposition (PECVD) system;

[0047] 3) Close the vacuum chamber, and use a mechanical pump and a Roots pump to evacuate. When the vacuum degree reaches below 0.1Pa, feed hydrogen gas with a flow rate of 40mL / min into the vacuum chamber. When the pressure reaches 300Pa, heat the sample stage to 400℃, Ni(NO 3 ) 2 and Mg(NO 3 ) 2 Decomposes at 400°C and forms NiO and MgO;

[0048] 4) After 2 hours of decomposition reaction, turn on the radio frequency power supply and apply 200W radio frequency power to form hydrogen plasma. Under the action of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com