Graphene preparation method

A technology of graphene and equipment, applied in the field of catalyst-based direct growth patterned graphene preparation, which can solve the problems of easy damage to the integrity of graphene, damage to graphene, and easy introduction of impurities, so as to achieve low porosity and reduce workload , The effect of high electron mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

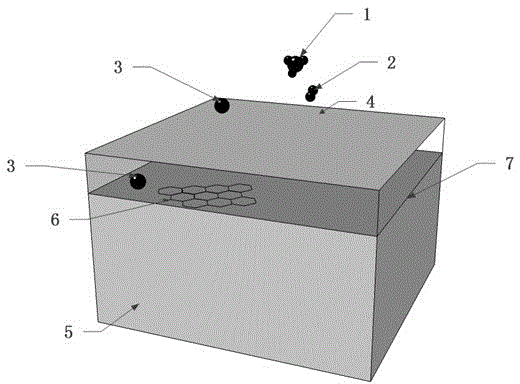

Method used

Image

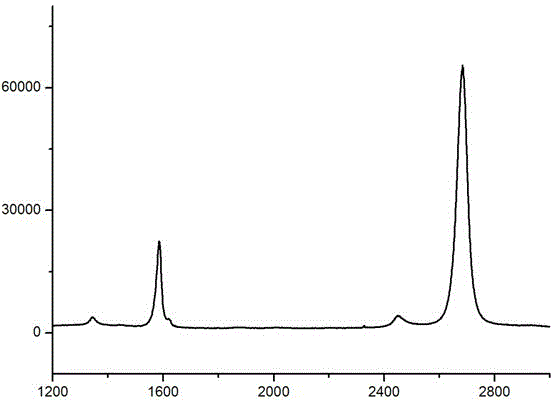

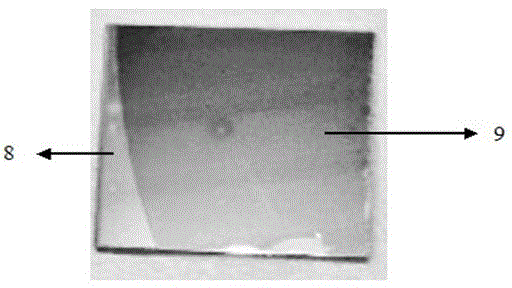

Examples

Embodiment 1

[0036] This example is based on SiO 2 The substrate is plated with a metal catalyst film made of metal material Cu to prepare graphene.

[0037] The first step: to polished SiO 2 Substrate substrate cleaning

[0038] Use a mixed solution of ammonia and hydrogen peroxide, hydrochloric acid and hydrogen peroxide to polish the SiO 2 The substrate substrate is cleaned, and the cleaning steps are divided into two stages:

[0039] The first stage: NH 4 OH, H 2 O 2 , H 2 O massage the ratio of 1:2:5 into a solution, and SiO 2 The substrate substrate is placed in the solution and soaked for 1-15 minutes. In this embodiment, we choose to soak for 2 minutes. After 2 minutes, it will be rinsed repeatedly with deionized water and dried to remove SiO 2 Organic residues on the surface of the substrate;

[0040] The second stage: the HCl, H 2 O 2 , H 2 O mole ratio 1:2:8 to make a solution, which will remove SiO from the surface organic residues 2 The substrate substrate is placed in the solution and...

Embodiment 2

[0056] In this embodiment, a metal catalyst film made of a metal material Ni is plated on a SiC substrate to prepare graphene.

[0057] The first step is to prepare a layer of SiO on the SiC substrate 2 The insulating layer, of course, this step can be omitted as required.

[0058] The second step: RCA cleaning the SiC to remove organic and inorganic chemical contaminants on the sample surface, the steps are the same as the first step in the first embodiment.

[0059] The third step: plating Ni metal catalyst film on the SiC substrate.

[0060] The cleaned SiC substrate is placed in a vacuum coating machine, and a layer of 50-2000nm Ni metal catalyst film is plated on the SiC substrate. The thickness of the metal catalyst film in this embodiment is 1500nm.

[0061] The fourth step: grow graphene film.

[0062] Place the SiC substrate substrate plated with Ni metal catalyst film on the sample stage of the graphene growth equipment, which is a radio frequency chemical vapor deposition equi...

Embodiment 3

[0066] In this embodiment, a metal catalyst film made of a metal material Cu-Ni alloy is plated on a sapphire substrate to prepare graphene.

[0067] The first step: cleaning the polished substrate

[0068] Wash the polished sapphire substrate with a mixed solution of ammonia and hydrogen peroxide, hydrochloric acid and hydrogen peroxide in sequence. The cleaning steps are divided into two stages:

[0069] The first stage: NH 4 OH, H 2 O 2 , H 2 O massage the ratio of 1:3:5 into a solution, and SiO 2 The substrate substrate is soaked in the solution for 1-15 minutes. In this embodiment, the immersion is selected for 8 minutes. After 8 minutes, it is rinsed repeatedly with deionized water and dried to remove the organic residues on the surface of the sapphire substrate. ;

[0070] The second stage: the HCl, H 2 O 2 , H 2 O mole ratio 1:3:7 to make a solution, put the sapphire substrate from which the organic residue on the surface is removed in the solution, soak for 1-15 minutes. In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com