Wrench machining integrated forming process

A molding process and an integrated technology, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems of difficult control of processing size, low processing efficiency, high surface roughness, etc., to reduce processing costs, improve processing efficiency, and precise size control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

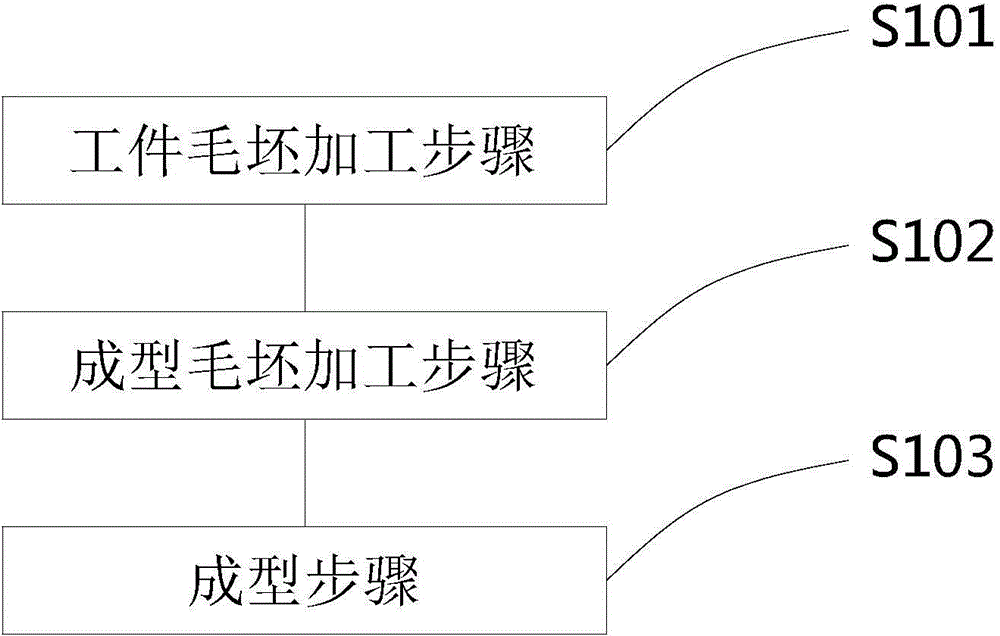

[0065] see figure 1 , the wrench processing integrated molding process provided in this embodiment includes:

[0066] Workpiece blank processing step S101: processing raw materials into workpiece blanks.

[0067] Forming blank processing step S102: the workpiece blank is clamped on the lathe through the spindle chuck, and a smooth forming blank for cold extrusion processing is obtained by turning.

[0068] Forming step S103: Put the forming blank into the mold, and obtain an integrally formed product through cold extrusion processing.

[0069] In this embodiment, the method of processing raw materials into workpiece blanks is an existing technology, which can be obtained by forging and pressing methods, and the shape of the workpiece blanks is elongated. In this way, the mold and process of forging the workpiece blank are simpler and the cost is reduced.

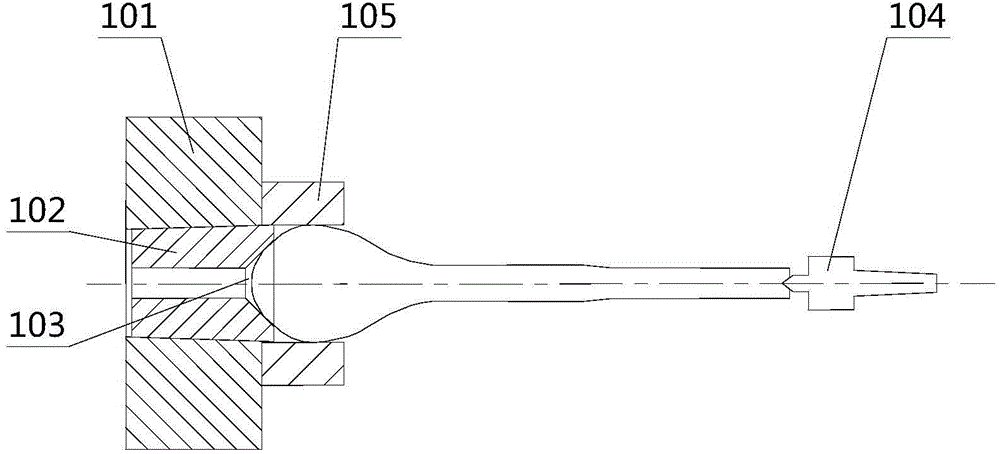

[0070] see figure 2 , in this embodiment, the spindle chuck includes an adjustment base 101 installed on a lathe. Th...

no. 2 example

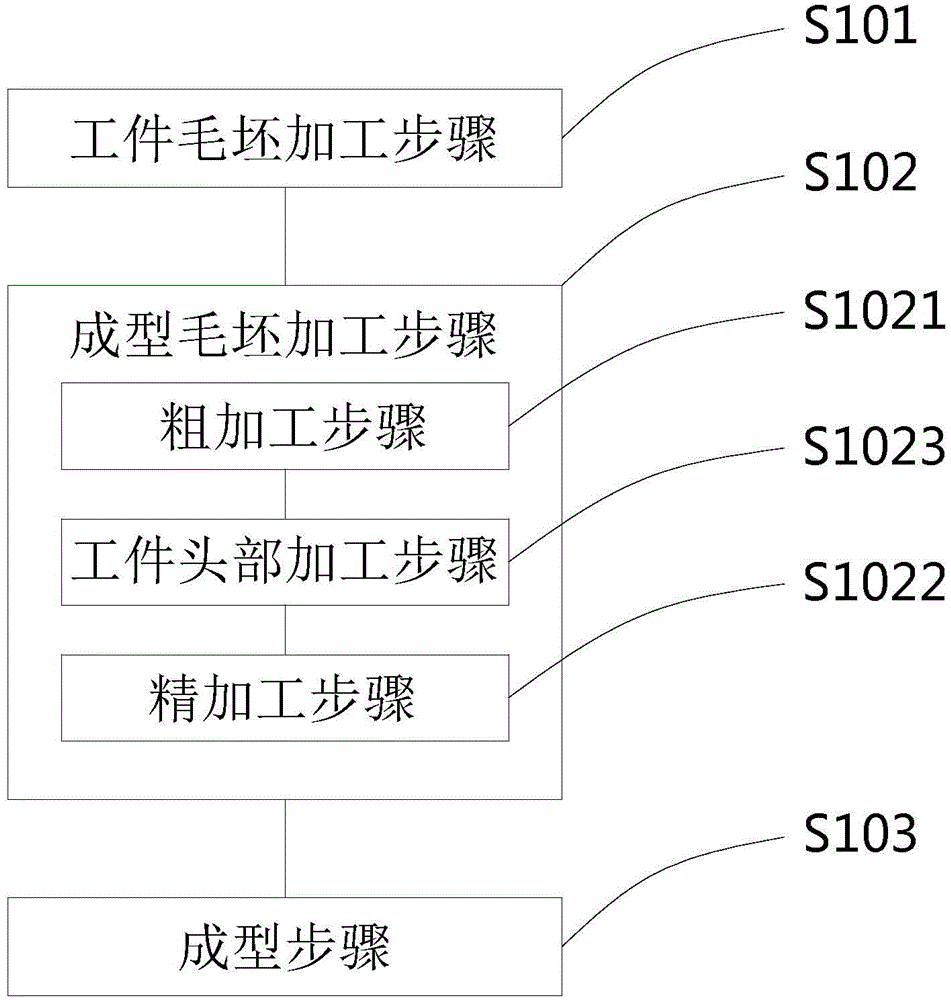

[0079] see image 3 , the wrench processing integrated molding process provided by this embodiment has the same principle and technical effect as the first embodiment. For a brief description, for the part not mentioned in this embodiment, you can refer to the corresponding content in the first embodiment . The wrench processing integrated molding process provided in this embodiment can be used to process various types of wrenches. The process, principle and technical effect of the process will be described in detail below by taking the processing of ratchet wrenches as an example:

[0080] see image 3 , in this embodiment, the forming blank processing step S102 includes a rough processing step S1021 and a finishing step S1022.

[0081] Specifically, the rough machining step S1021: the workpiece blank is clamped on the lathe by the spindle chuck, and the workpiece blank is rough-turned.

[0082] Finishing step S1022: the rough-machined workpiece blank is clamped by the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com