High-temperature solar blind ultraviolet photoelectric tube and manufacturing method thereof

A production method and ultraviolet light technology, which are applied in the field of photoelectric tubes, can solve the problems of gaps and cannot fully meet the development and production needs of military aero-engine systems, and achieve high response speed, visible light and infrared non-response quality, high reliability and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

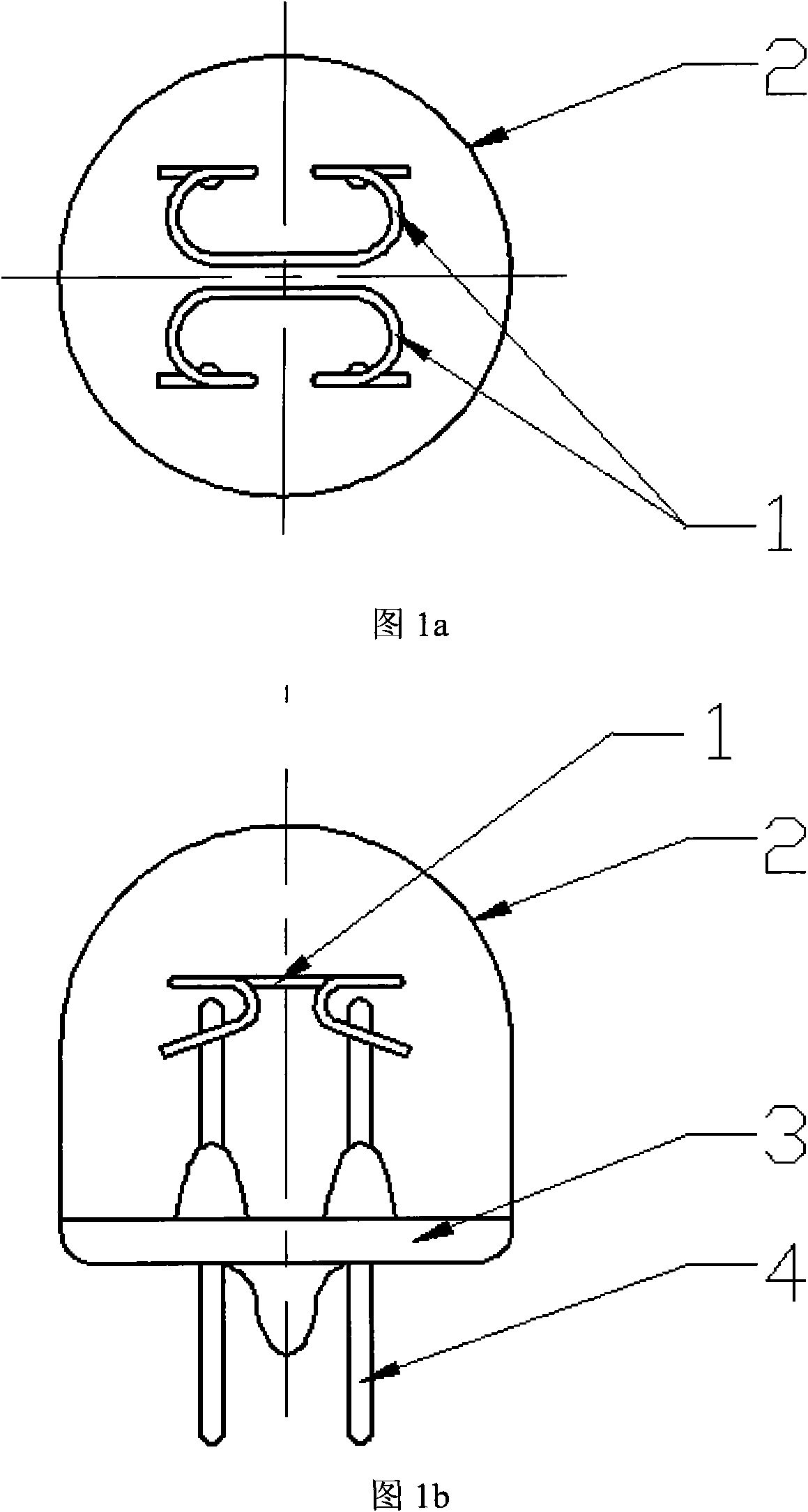

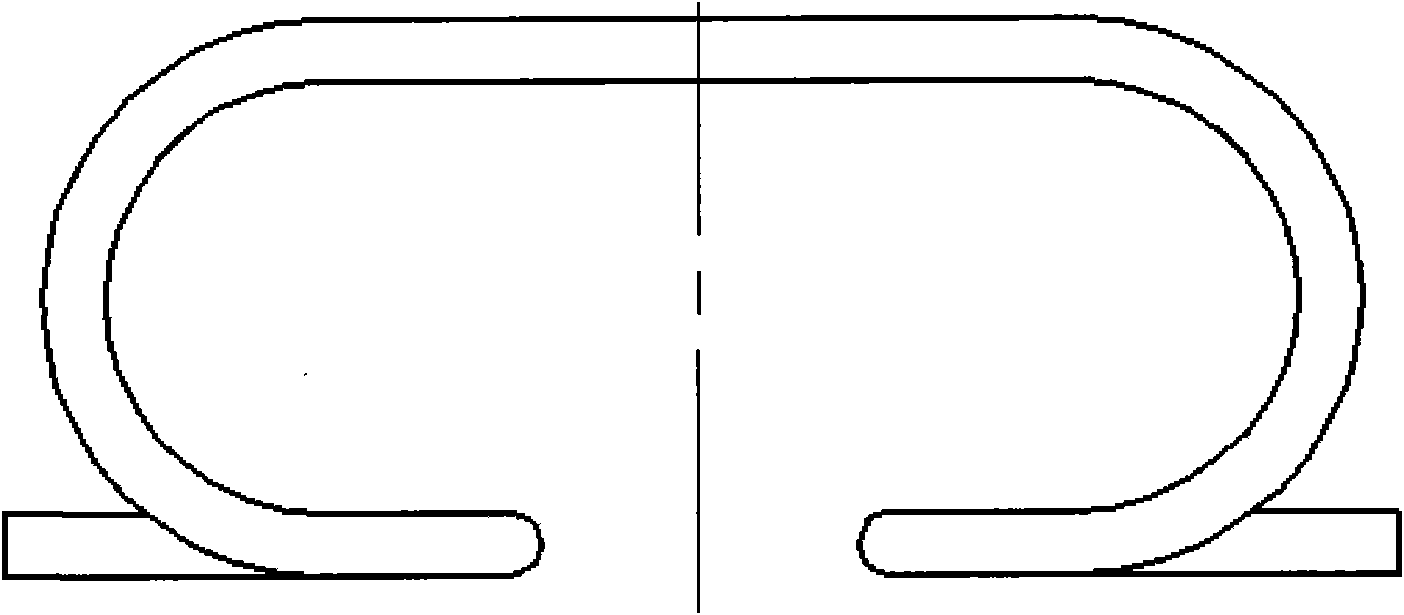

[0016] Such as figure 1 shown. A high-temperature sun-blind ultraviolet photoelectric tube, including a core column 3, the top of the core column is covered with a molybdenum group transparent glass bulb 2 sealed with the core column 3, and two pairs of metal straight rods 4 are installed on the core column 3 Among them, one end of the metal straight rod 4 extends into the molybdenum group transparent glass envelope 2, and the other end passes through the bottom of the stem 3, and two molybdenum electrodes 1 are also arranged in the molybdenum group transparent glass envelope 2, and the molybdenum electrodes 1 are respectively It is bent into a disconnected oval, and the disconnected ends of the molybdenum electrode 1 are respectively bent downwards into pins inclined relative to the oblong surface. The pins of a molybdenum electrode are connected with a pair of metal straight rods one by one, and the two molybdenum electrodes The oblong surfaces of the electrodes are paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com