An anode in a field emission light source and a field emission light source comprising the anode

A technology of emitting light source and anode, applied in the direction of electron emission electrode/cathode, fluorescent screen lamp, gas discharge lamp parts, etc., can solve the problems of charge accumulation, complex manufacturing, energy loss of emission light source, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

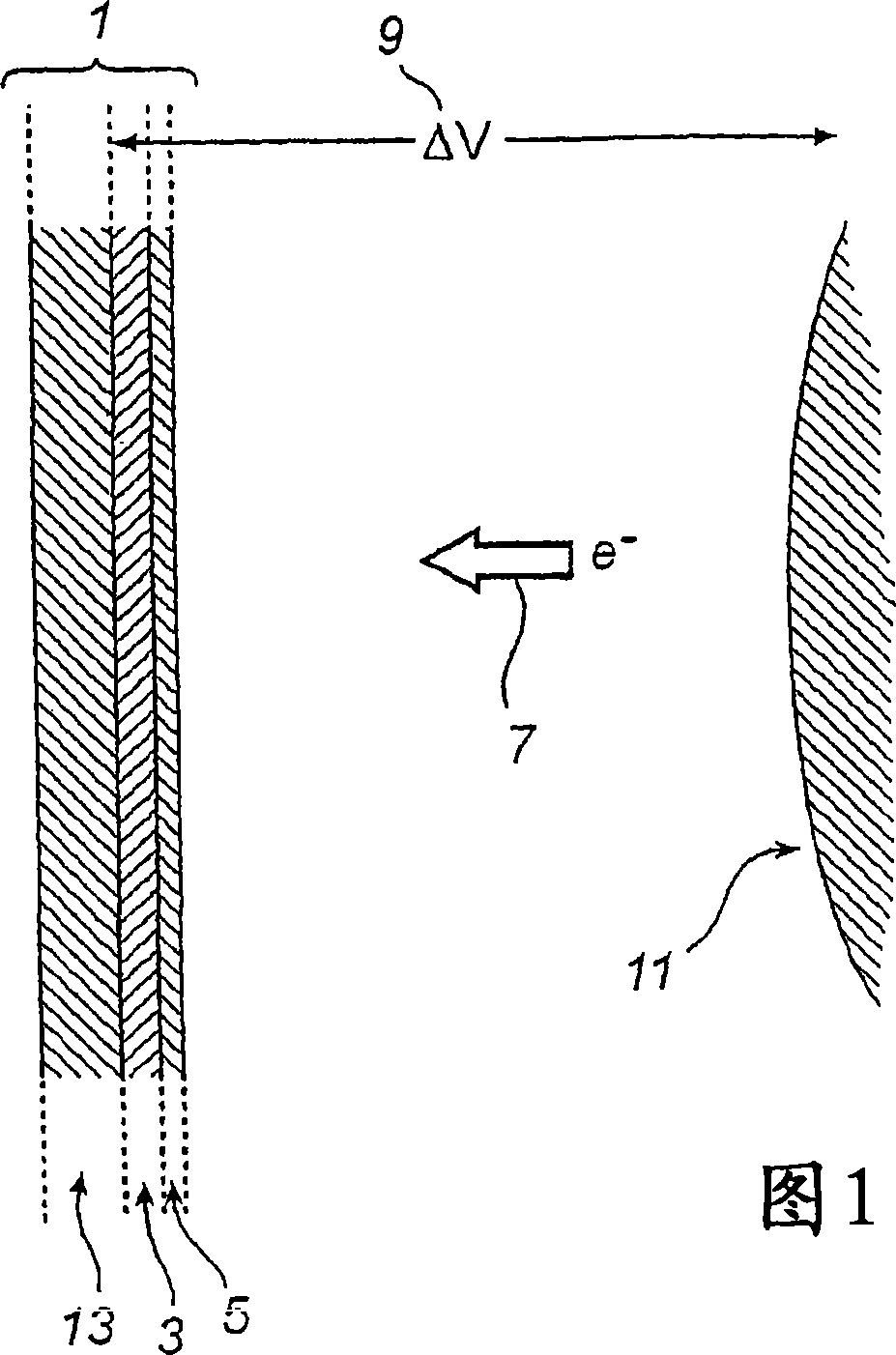

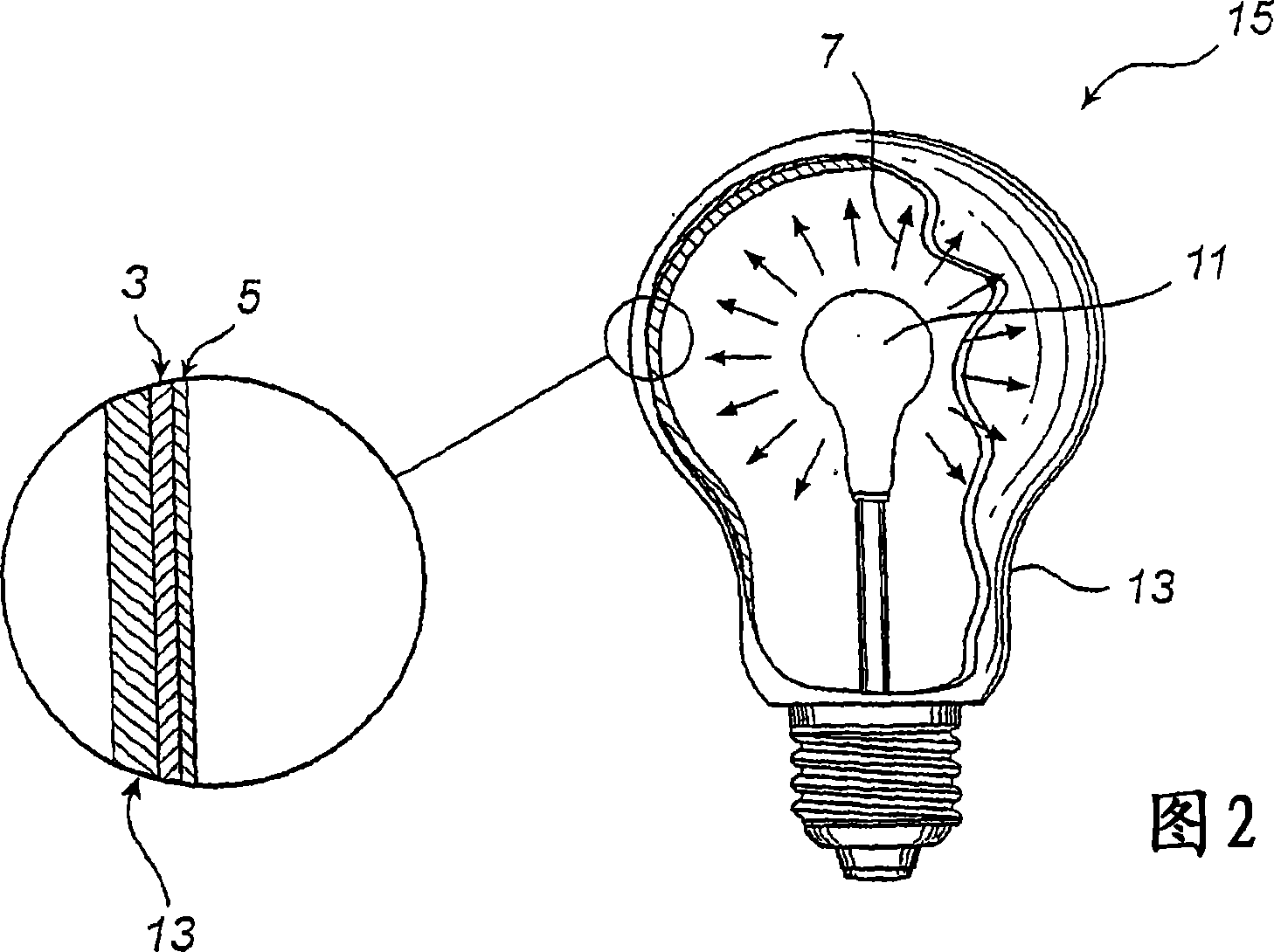

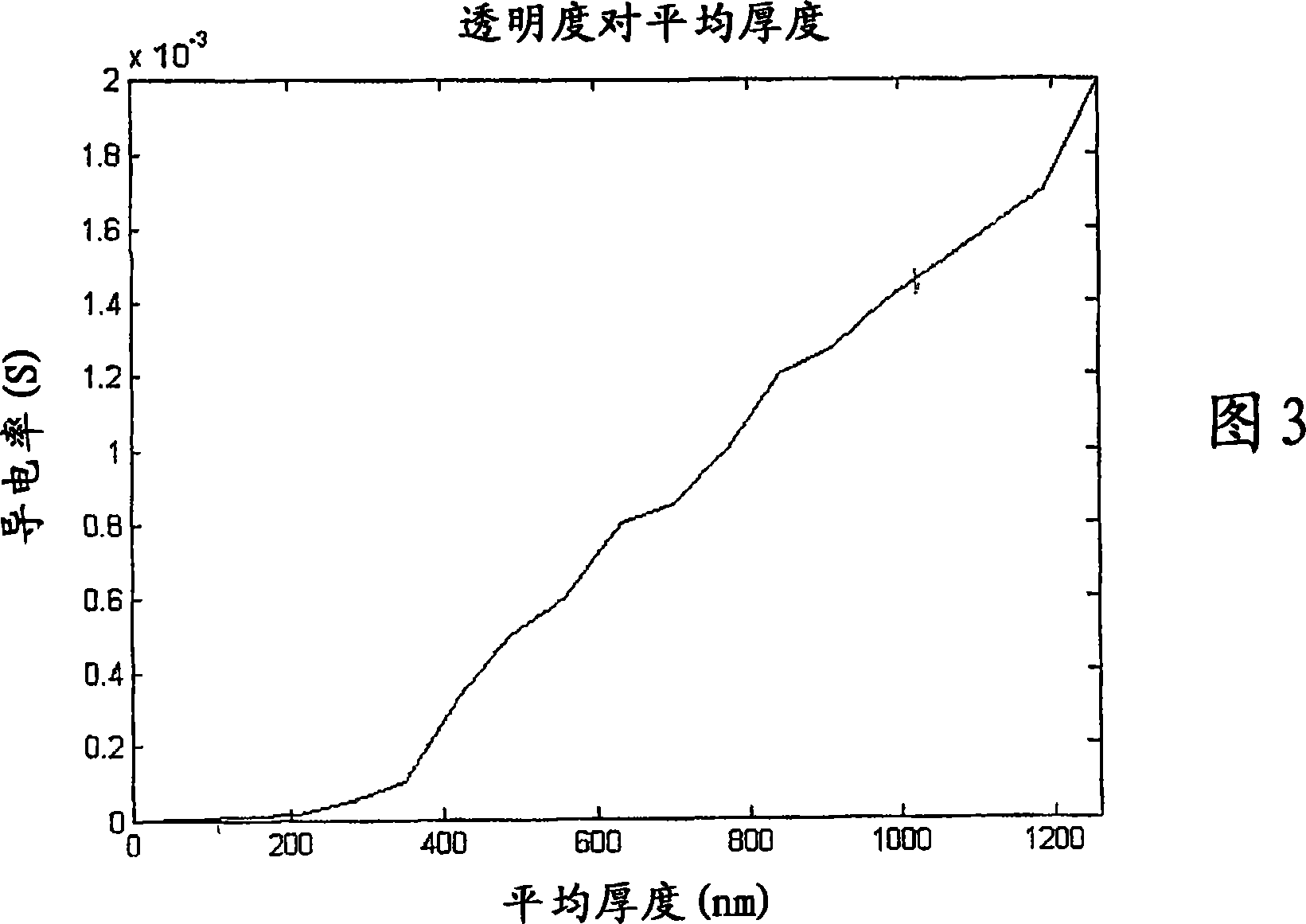

[0023] In Fig. 1 an embodiment of an anode 1 in a field emission light source according to the invention is disclosed. The anode 1 comprises a conductive layer 3 and a light-emitting layer 5 that emits light when excited by electron bombardment 7 caused by a potential difference 9 between the conductive layer 3 and the cathode 11 . The light emitting layer 5 is disposed between the conductive layer 3 and the cathode 11 . The conductive layer 3 is a transparent conductive layer 3 . The light-emitting layer 5 directly adjoins the transparent conductive layer 3 . The thickness of the transparent conductive layer 3 is 100-1000 nm, more preferably 400-600 nm and still more preferably 450-550 nm. The potential difference 9, ΔV is 4-12KV, and more preferably 5-11KV.

[0024] In one embodiment the transparent conductive layer is indium tin oxide (ITO) and in another embodiment the transparent conductive layer is zinc oxide (ZnO).

[0025] In this particular embodiment, the anode 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com