Low-temperature plasma waste gas purification device

A low-temperature plasma and exhaust gas purification technology, which is applied in solid separation, gas treatment, electrostatic separation, etc., can solve the problems of small processing capacity, low electric field strength, and difficulty in meeting the needs of large air volume and high-concentration exhaust gas treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

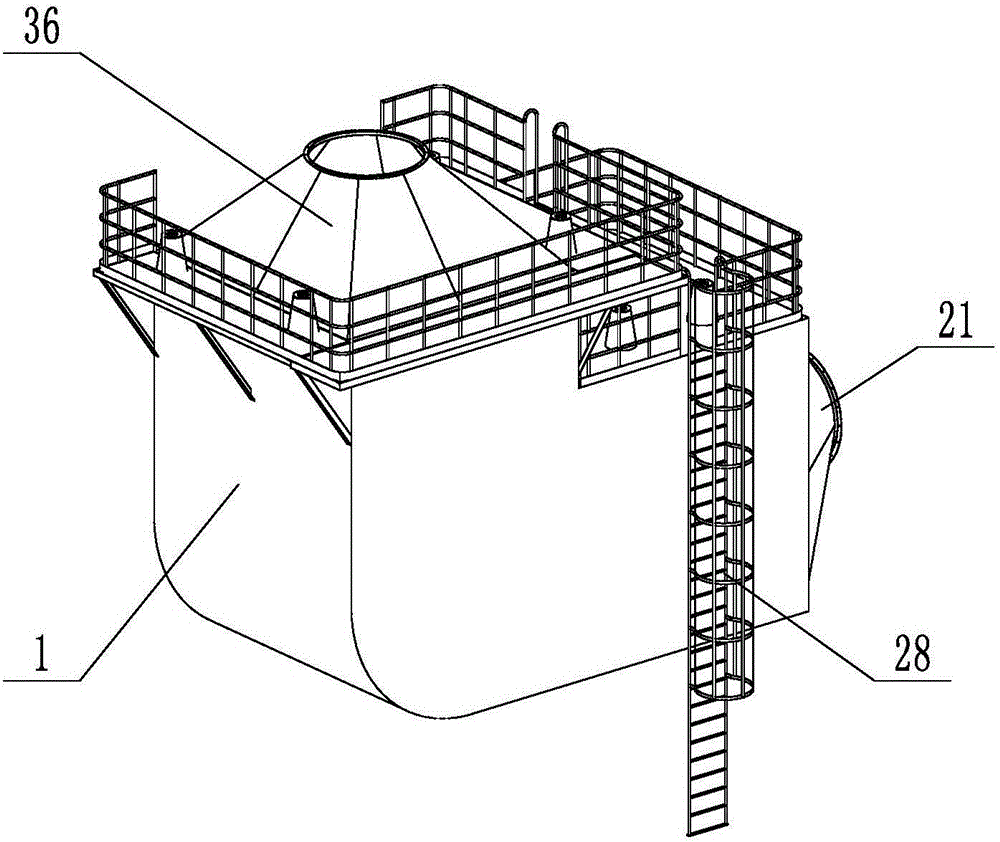

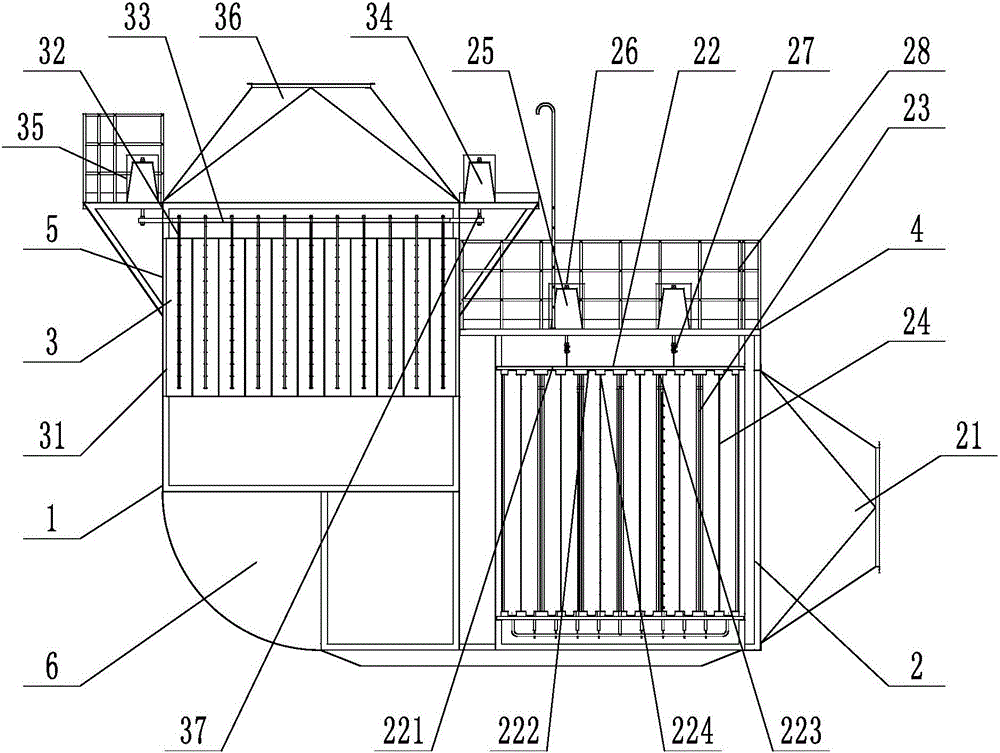

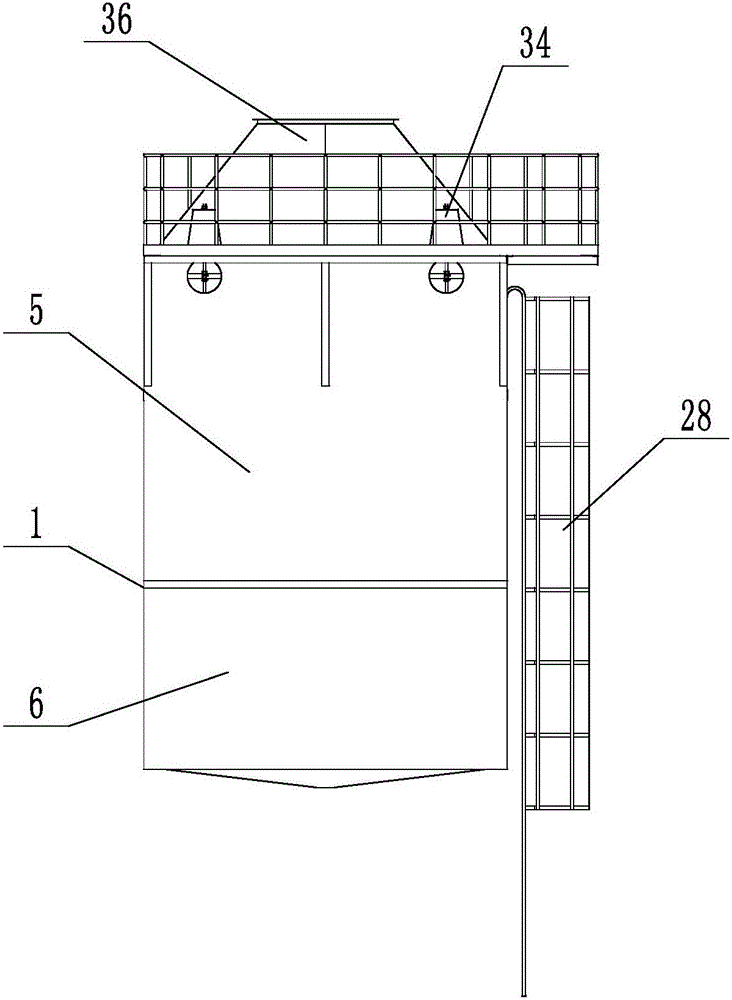

[0020] Such as Figure 1-5 As shown, the present invention includes a casing 1, a dust removal system 2 and an odor removal system 3, the casing 1 is divided into a horizontal casing 4 and a vertical casing 5, and between the horizontal casing 4 and the vertical casing 5 Connected by an arc-shaped housing 6, the dust removal system 2 is installed inside the horizontal housing 4, and the deodorizing system 3 is installed inside the longitudinal housing 5;

[0021] The dust removal system 2 includes an air inlet tube 21, an electrode installation beam 22, a dust removal anode tube 23, a dust removal cathode tube 24, a ceramic insulating seat 25 and a protective cover 26,

[0022] The air inlet tube 21 is installed at the right end of the transverse housing 4, the electrode mounting beam 22 is divided into an anode beam 221 and a cathode beam 222, and the anode beam 221 and the cathode beam 222 are installed parallel to each other inside the transverse housing 4 On the two side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com