Manufacturing technique of heavy piece-weight thick steel plate used for offshore wind turbine tower tube

A manufacturing process and technology for wind power towers, which are applied in the field of manufacturing processes of large single-weight and thick steel plates for offshore wind power towers, can solve the problems of difficulty in meeting the single-weight requirements of wind power towers, low production efficiency, and low yield, and achieve good results. The effect of comprehensive mechanical properties, high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

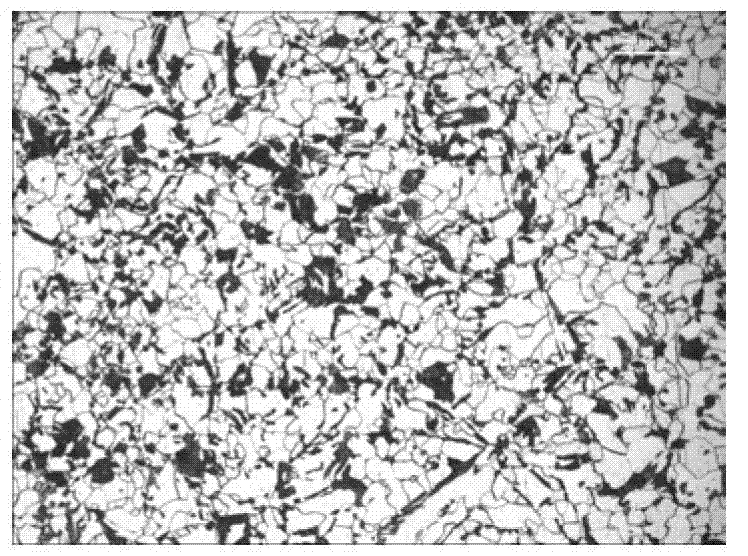

Image

Examples

Embodiment 1

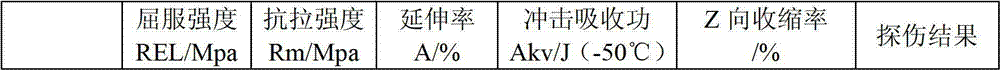

[0031] Example 1: Production of 95*2500*18800mm specification S355G8+N steel plates for manufacturing offshore wind power towers, with a unit weight of 35t:

[0032] 1) Smelting of high-purity molten steel. After the molten steel is smelted in a converter, LF+RH double refining is carried out. LF refining fully removes inclusions and desulfurization. RH vacuum treatment maintains a vacuum degree of 0.8Torr for 12 minutes to further remove inclusions and gases. The gas [O] 10ppm, [H] 1.5ppm.

[0033] 2) The molten steel continuous casting process adopts the whole process of protective pouring, and uses electromagnetic stirring, constant-speed pouring and other means. The low-magnification analysis results of the cast slab have a central segregation of class C 1.0, and there are no defects such as intermediate cracks and looseness. Two continuous casting slabs of 300*2100*4100mm were produced, and the analysis results of the smelting composition are as follows:

[0034] Table 1 E...

Embodiment 2

[0047] Example 2: Production of 95*2500*18800mm specification S355G8+N steel plates for manufacturing offshore wind power towers, with a unit weight of 35t:

[0048] 1) Smelting of high-purity molten steel. After the molten steel is smelted in a converter, LF+RH double refining is carried out. LF refining fully removes inclusions and desulfurization. RH vacuum treatment maintains a vacuum degree of 0.8Torr for 15 minutes to further remove inclusions and gases. The gas [O] 8ppm, [H] 1.2ppm.

[0049] 2) The molten steel continuous casting process adopts the whole process of protective pouring, and uses electromagnetic stirring, constant-speed pouring and other means. The low-magnification analysis results of the cast slab have a central segregation of class C 1.0, and there are no defects such as intermediate cracks and looseness. Two continuous casting slabs of 300*2100*4100mm were produced, and the analysis results of the smelting composition are as follows:

[0050] Table 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com