Transversal-hole temperature-insulating concrete hollow brick

A technology of hollow blocks and concrete, which is applied in the direction of building components, buildings, building structures, etc., can solve problems such as easy formation of voids, influence on thermal insulation coefficient, breaking of upper and lower horizontal connecting plates, etc., achieve simple manufacturing process, improve thermal insulation coefficient, Ease of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

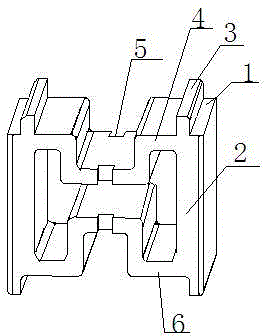

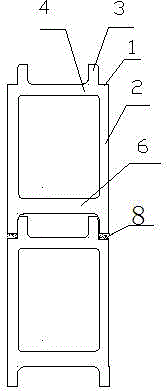

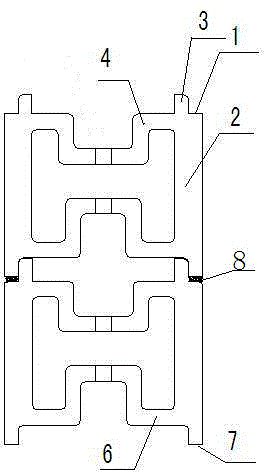

[0021] Such as figure 1 , figure 2 , image 3 As shown: the width of the side plate (2) of the block is designed to be aligned with the inner surface of the upper rib of the block to form a line, so that the upper and lower pressure of the block is no longer caused by the upper and lower connecting plates (4) of the block and the lower side of the block. The connection plate (6) bears it, and the up and down pressure is directly stressed on the upper convex rib (3) on the top of the side plate and the contact surface (1) of the block, changing the impact of the up and down pressure on the stress area of the connection plate (4) and the block The stress buffering of the lower connecting plate (6) makes the upper and lower connecting plates of the block no longer subject to the upper and lower pressure of the block, effectively solving the problem that the upper and lower connecting plates are prone to cracking or being crushed in the concrete hollow block, and improving its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com