Intelligent compression type air cooler

An air cooler and intelligent compression technology, which is applied in the direction of irreversible cycle compressors, compressors, refrigerators, etc., to achieve the effect of less consumables, high heat transfer coefficient, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

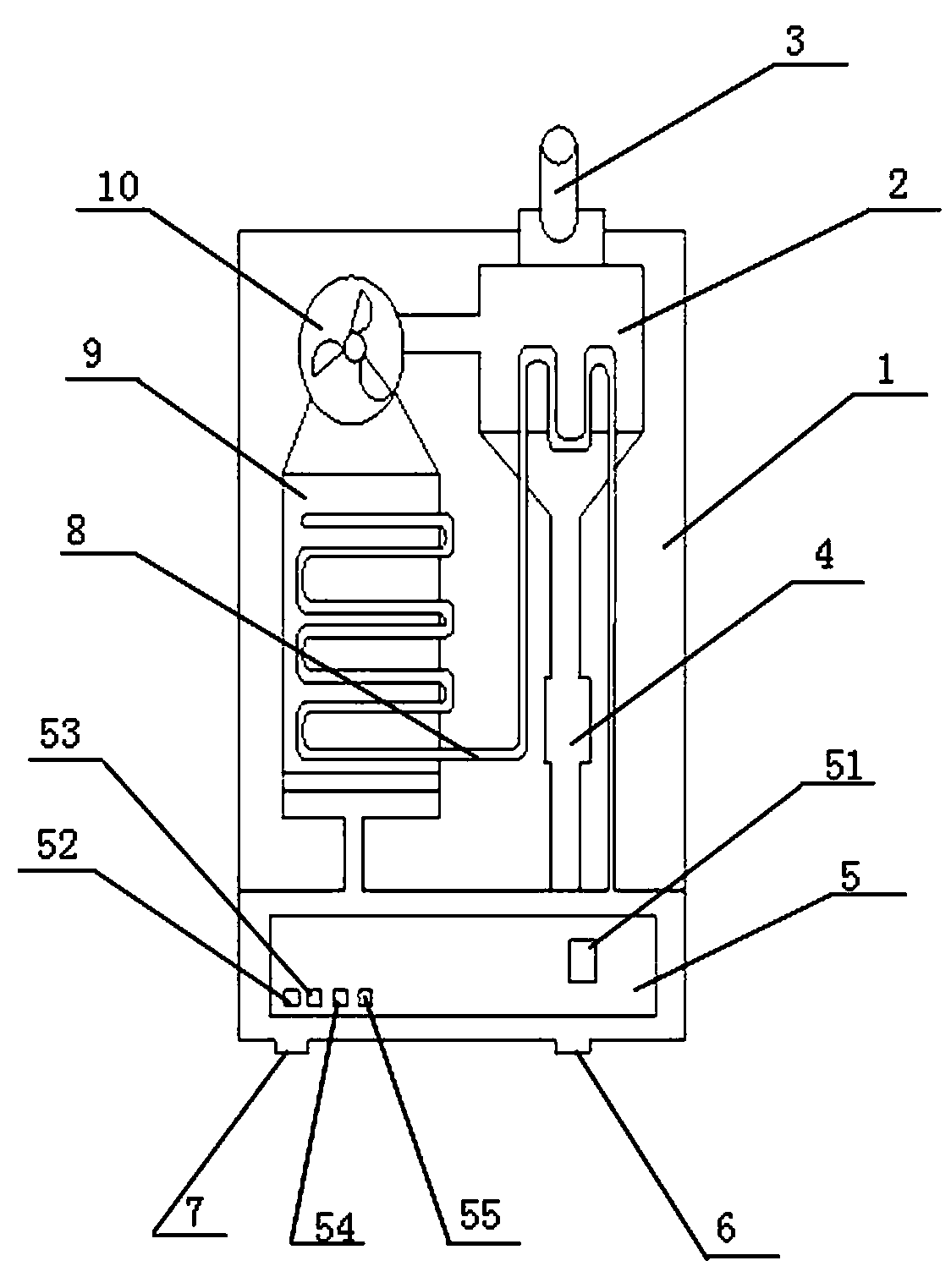

[0018] An intelligent compressed air cooler, comprising an upper part of a shell and a lower part of the shell, wherein the upper part of the shell includes a liquid collecting tank 2, a heat dissipation channel 3, a throttle valve 4, a condensation heat exchange tube 8, and a compressor 9 , The anti-movement and anti-wind back device 10, the heat dissipation channel 3 is located at the top of the upper part of the housing, and the lower part is provided with a liquid collecting tank 2. The liquid collecting tank 2 is located at the right end of the upper part of the housing and the lower part of the heat dissipation channel 3. The upper part is provided with a heat dissipation channel 3, the lower part is provided with a throttle valve 4, and the left part is connected with the anti-movement back-wind prevention device 10. The throttle valve 4 is located in the lower part of the collecting tank 2, and the left part is provided with a compressor 9. The lower part is provided wit...

Embodiment 2

[0020] The intelligent processor 5 includes a display screen 51, a temperature adjustment key 52, a humidity adjustment key 53, a switch key 54, and a scene mode key 55. The temperature adjustment key 52 is located at the lower left of the intelligent processor 5, with Humidity adjustment key 53, the humidity adjustment key 53 is located at the lower left of the intelligent processor 5, the left side is provided with a temperature adjustment key 52, and the right side is provided with an on-off key 54. The humidity adjustment key 53 is set in the temperature adjustment key 52 and The middle position of the switch key 54, the switch key 54 is located at the lower left of the intelligent processor 5, the left side is provided with a humidity control key 53, the right side is provided with a scene mode key 55, the switch key 54 is set on the humidity control key 53 In the middle of the scene mode key 55, the scene mode key 55 is located at the lower left of the intelligent processo...

Embodiment 3

[0022] The condensation heat exchange tube 8 is connected in a serpentine shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com