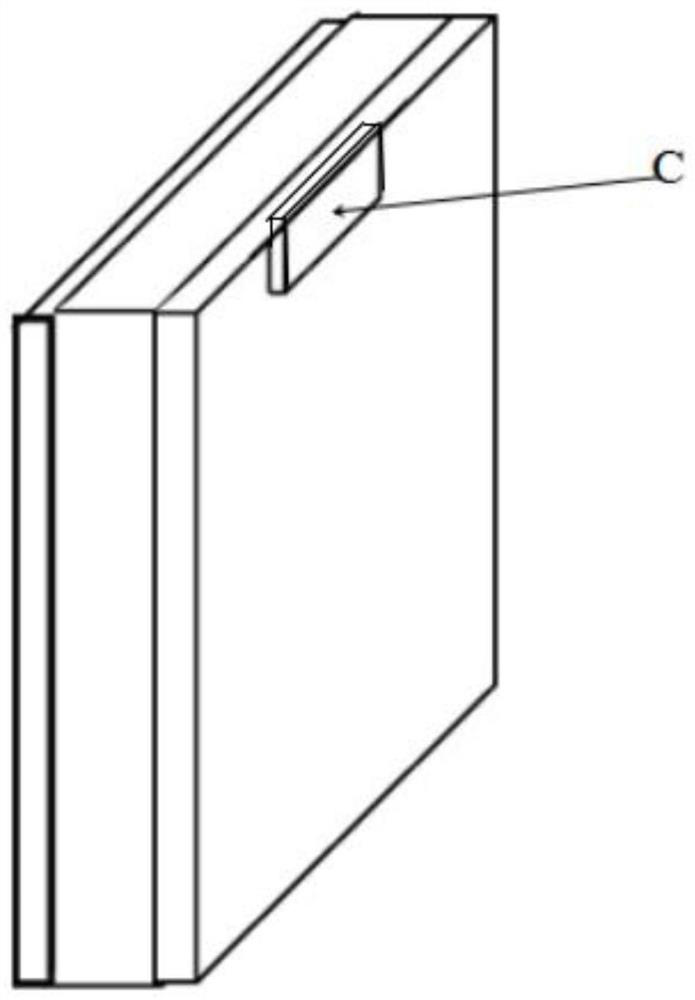

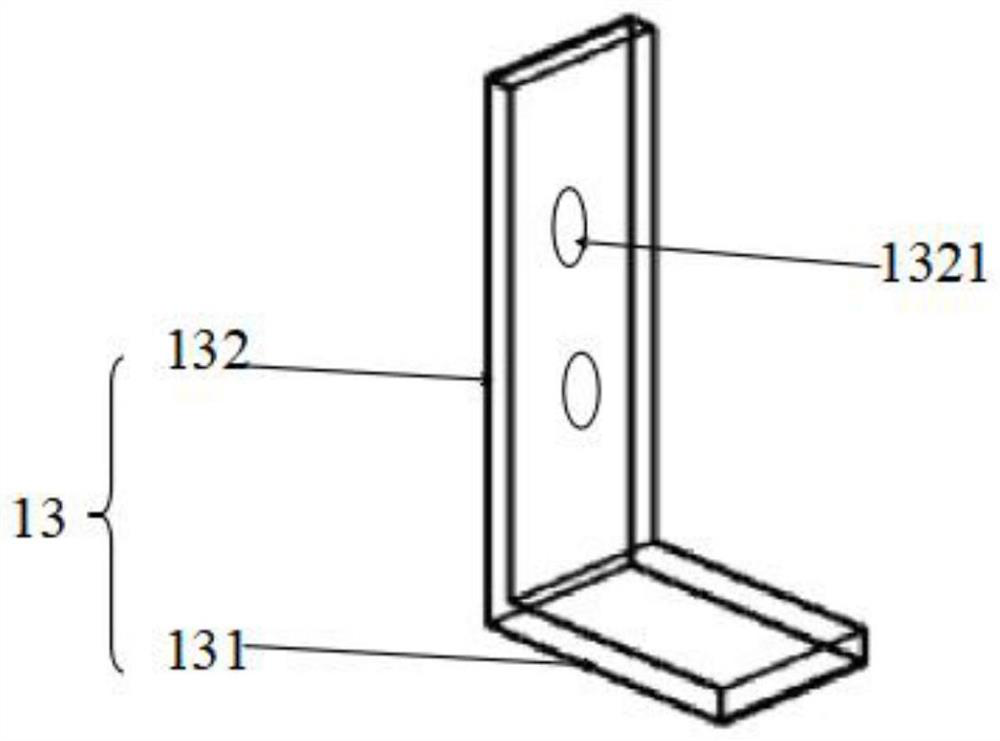

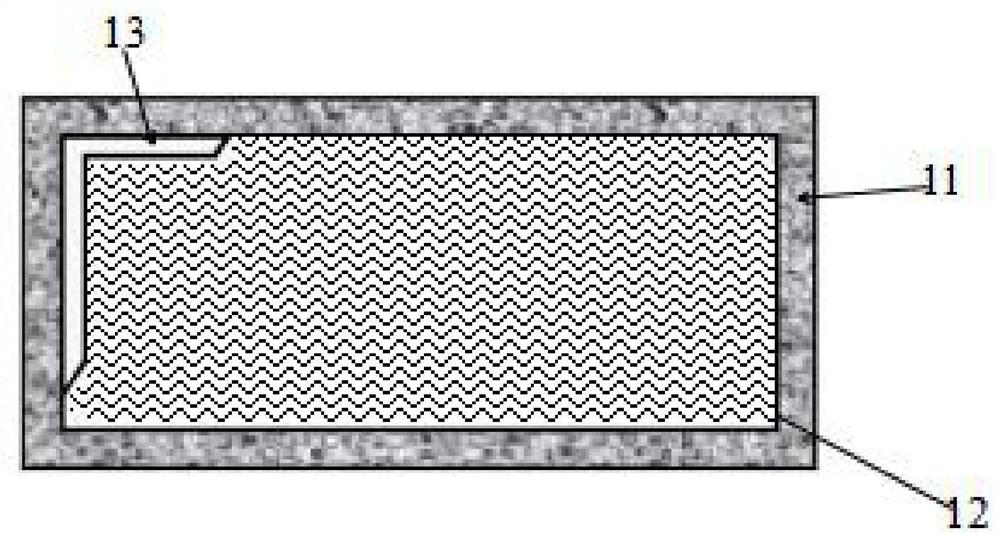

Integrated insulation board with built-in connecting piece and preparation method of integrated insulation board

A connector and one-piece technology, applied in thermal insulation, building components, manufacturing tools, etc., can solve problems such as the weight of thermal insulation boards, the influence of connection stability, and the thickness of cement boards, so as to improve thermal insulation coefficient and reduce installation difficulty , Improve the effect of safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097]The preparation method of the thermal insulation board of this embodiment is as follows:

[0098](1) According to mass percentage, mix 42.5R cement 34.5%, 0.01-5mm quartz sand 60.55%, Beijing microbeads 1%, polycarboxylic acid water reducing agent 1.5%, lithium carbonate 0.1%, sodium gluconate 0.05%, glass fiber (6mm, Taishan easy-dispersing glass fiber) 0.3% and 2.0% of the water-based polyacrylate emulsion are mixed with water together to control the water-binder ratio to 0.25. At this time, the glue-sand ratio is also within the preset range, and the mixture is evenly stirred to make the initial automatic flow The degree of fluidity is 234mm cement slurry.

[0099](2) Build the mold. Place the mold frame (the inner dimension of the mold frame is 450mm*300mm*40mm) on the surface of the plate. Before injection molding, a layer of nano silica emulsion with a concentration of 10% was applied to the inner wall of the mold frame and the surface of the plate.

[0100](3) Inject a layer of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com