Fireproof cloth and preparation method thereof

A technology of fireproof cloth and fireproof fiber, which is applied in the manufacture of fireproof and flame-retardant filaments, single-component polyamide artificial filaments, etc., which can solve the problems of large-scale use restrictions, poor air tightness of fireproof cloth, and easy to stink and mold , to achieve the effects of strong practicability, comfortable working environment and high thermal insulation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention proposes a method for preparing fireproof cloth, preparing hollow glass microspheres loaded with black titanium dioxide and hafnium oxide; Fiber; then use fireproof fiber to weave into fireproof cloth. The weaving method of using fireproof fibers to weave fireproof cloth can be pure spinning or blending.

[0039] Specifically, the preparation of hollow glass microspheres loaded with black titanium dioxide and hafnium oxide includes the following steps:

[0040] Step S1, preparing hollow glass microspheres loaded with black titanium dioxide;

[0041] Step S2, using direct chemical deposition to deposit hafnium oxide on the hollow glass microspheres loaded with black titanium dioxide, thereby forming hollow glass microspheres loaded with black titanium dioxide and hafnium oxide.

[0042] Here, the hollow glass microspheres are not only used as the carrier of black titanium dioxide and hafnium oxide, but also used to provide higher emissivity; while the haf...

no. 1 example

[0072] Mix 0.2 mol / L tetrabutyl titanate ethanol solution with hollow glass microspheres with a density of 0.5 g / mL to form a suspension; the mass fraction of the hollow glass microspheres in the suspension is 1 wt%. Then, the dispersant of model SIM6492.72, accounting for 0.1 wt% of the mass fraction of the suspension, was slowly added dropwise into the suspension; the time for adding the dispersant was controlled to 0.5h through the dropping funnel.

[0073] Add the suspension after dropping the dispersant into the hydrothermal kettle, place the hydrothermal kettle in an oven for stage heating to obtain the first solid substance; wherein, the stage heating program is heating at 150°C for 2 hours, and heating at 180°C Heating for 5h and heating at 220°C for 3h. After the staged heating reaction is completed, the first solid matter is filtered and dried overnight in an oven at 100° C. to obtain hollow glass microspheres loaded with ordinary titanium dioxide.

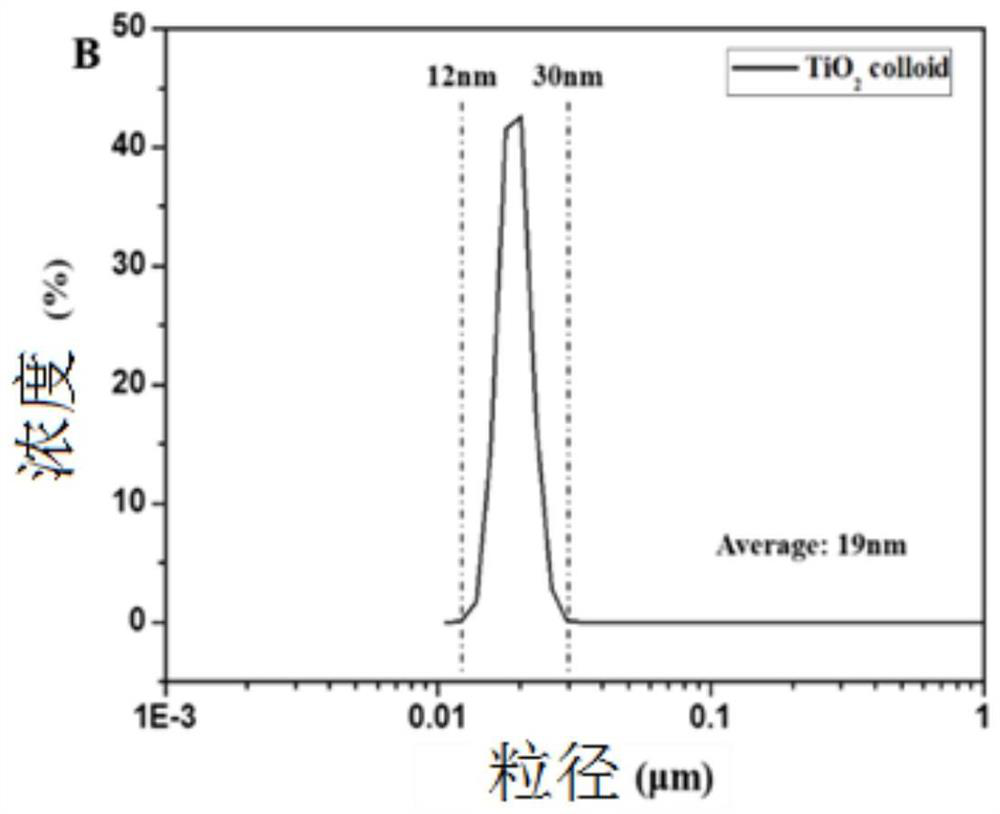

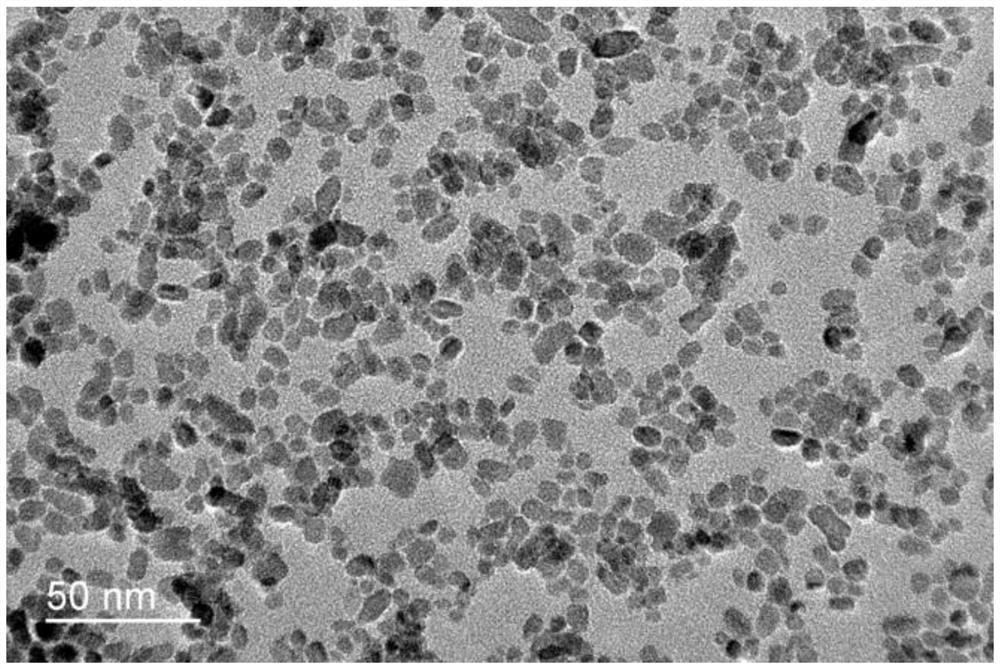

[0074] The holl...

no. 2 example

[0080] Mix 0.3 mol / L titanium tetrahydrofuran isopropoxide solution with hollow glass microspheres with a density of 1.0 g / mL to form a suspension; the mass fraction of the hollow glass microspheres in the suspension is 2 wt%. Then, the dispersant of model SIB1824.82, accounting for 0.3 wt% of the mass fraction of the suspension, was slowly added dropwise into the suspension; the time for adding the dispersant was controlled to 0.8h through the dropping funnel.

[0081] Add the suspension after dropping the dispersant into the hydrothermal kettle, place the hydrothermal kettle in an oven for stage heating to obtain the first solid substance; wherein, the stage heating program is heating at 150°C for 3 hours, heating at 180°C Heating for 6h and heating at 220°C for 4h. After the staged heating reaction is completed, the first solid matter is filtered and dried overnight in an oven at 100° C. to obtain hollow glass microspheres loaded with ordinary titanium dioxide.

[0082] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com