Focusing type cold cathode X-ray tube

A technology of X-ray tube and cold cathode, which is applied in the direction of X-ray tube electrodes, X-ray tube parts, X-ray tube inflatable materials, etc. It can solve the problem of insufficient defocusing of electrons, poor atmosphere, and small area of electrons acting on the anode, etc. problem, to achieve the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

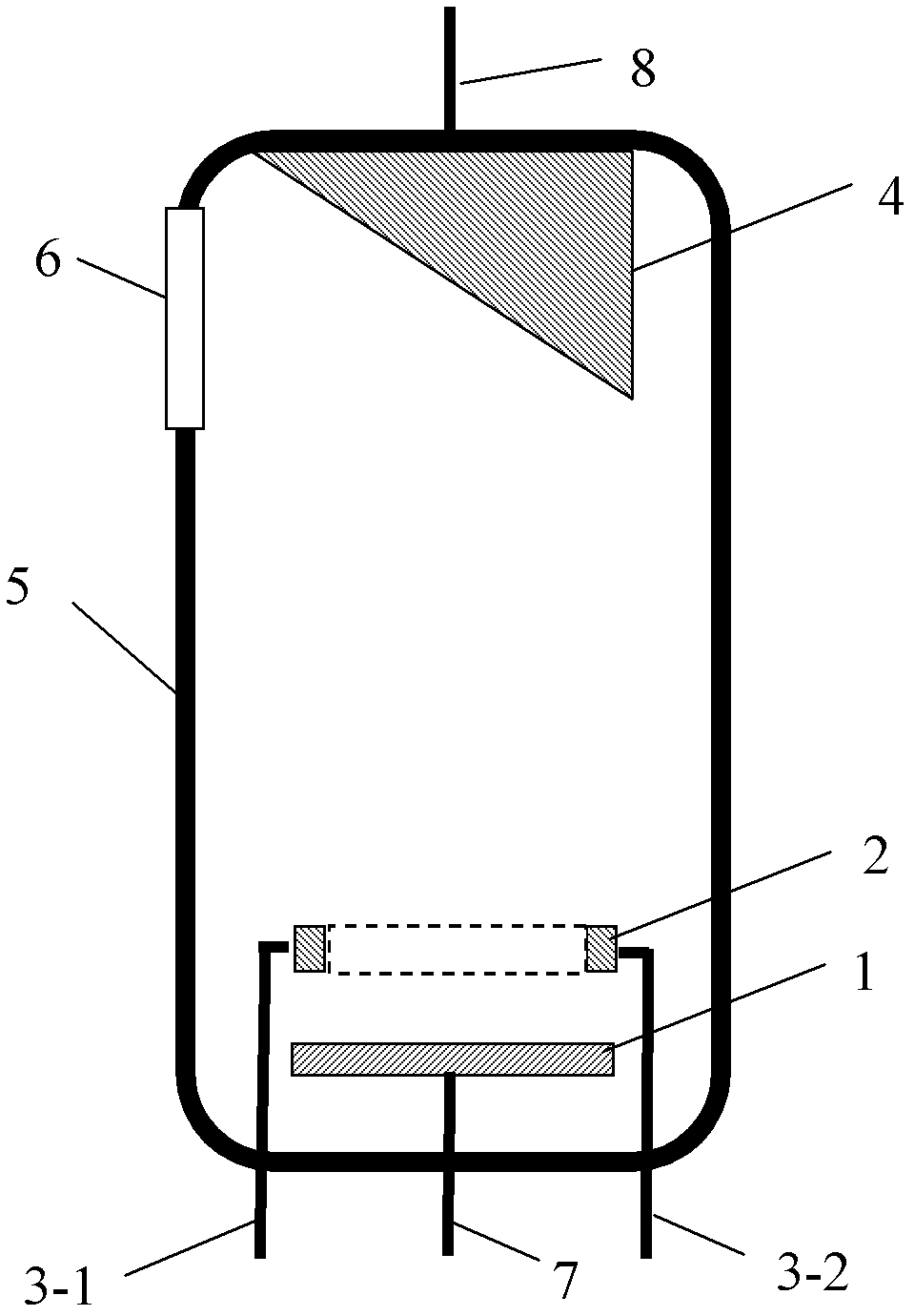

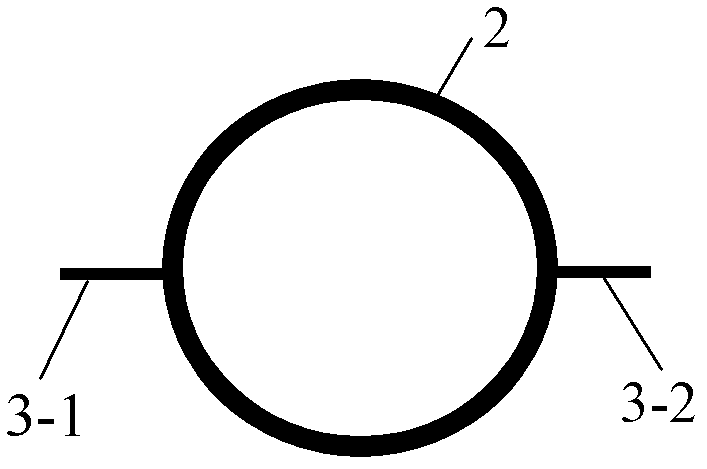

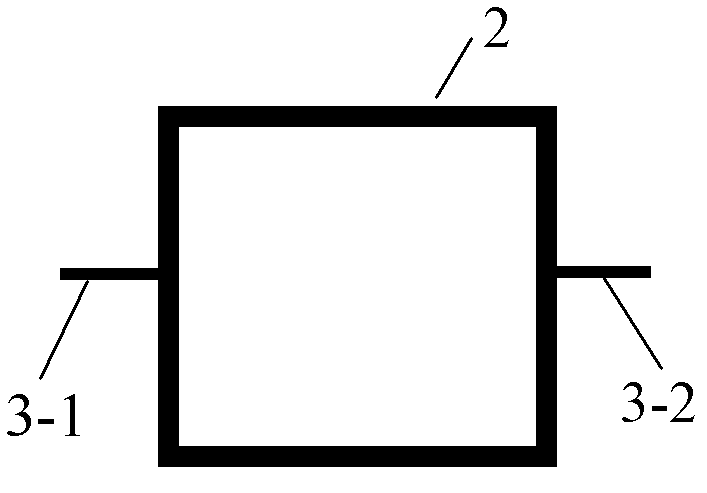

[0023] Embodiment: the focus type cold cathode X-ray tube of the present invention, such as figure 1 As shown, it includes a field emission cold cathode 1, a filament grid 2 composed of a closed filament, an anode 4, an X-ray tube shell 5 and a ray exit window 6; the field emission cold cathode 1 and the anode 4 are respectively arranged The two ends inside the X-ray tube casing 5 are drawn to the outside of the X-ray tube casing 5 through the cathode extraction electrode 7 and the anode extraction electrode 8 respectively; the filament grid 2 is arranged in the field Between the emission cold cathode 1 and the anode 4, its two sides are respectively drawn to the outside of the X-ray tube shell 5 through two extraction electrodes 3-1, 3-2; the shape of the filament grid 2 is The same circular or square shape as the field emission cold cathode 1, such as figure 2 and 3 As shown; the anode 4 has a slope for electron bombardment to generate X-rays, and the ray exit window 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com