Helix slow wave structure

A technology of slow-wave structure and helix, applied in the field of slow-wave structure, can solve the problems of difficult general application, complex process, expensive price, etc., and achieve the effect of improving performance, improving heat capacity and reliability, and improving heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

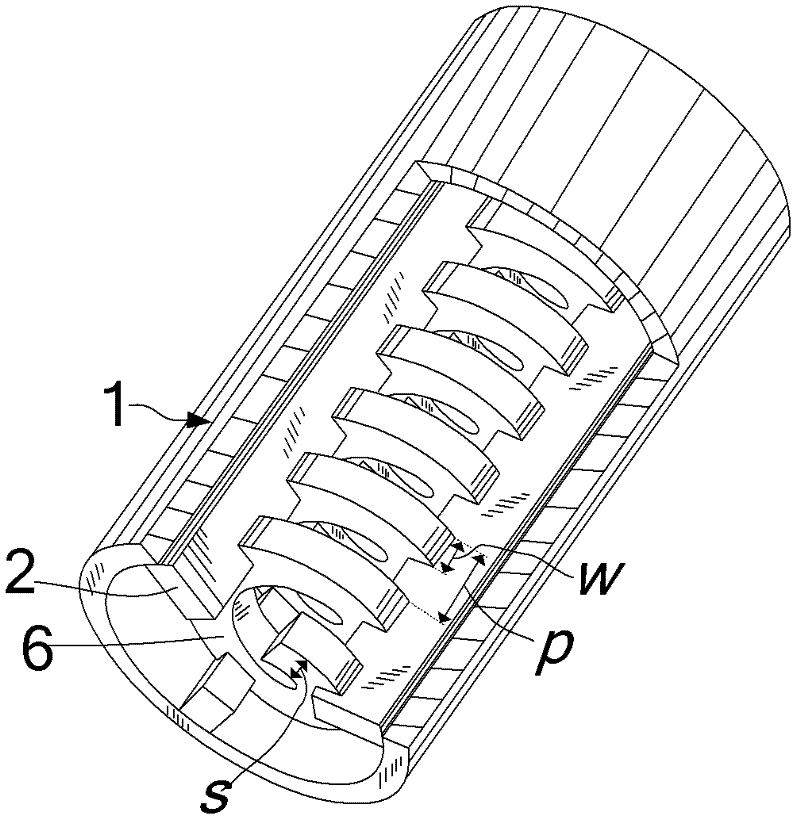

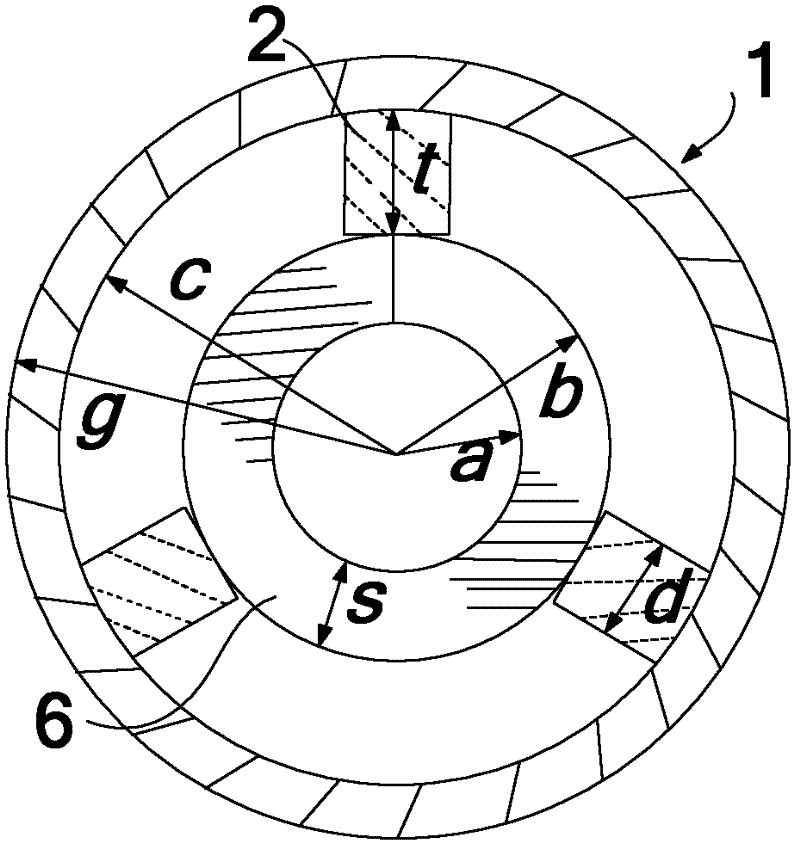

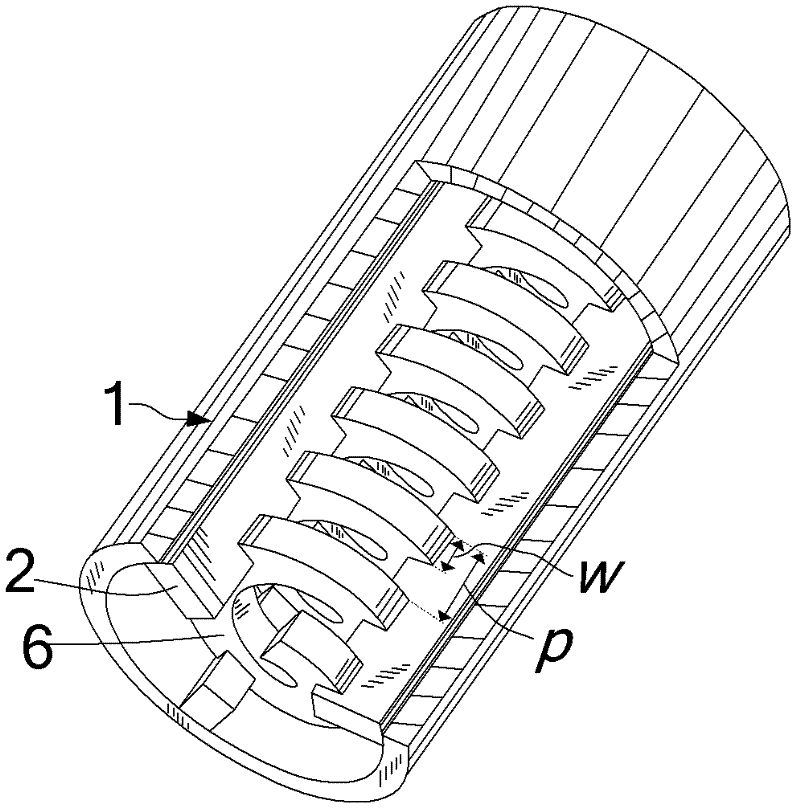

[0023] A helical slow-wave structure, such as Figure 3-5 As shown, it includes a helix 6, a tube shell 1 and three medium holding rods 2. The inner diameter of the helix 6 is a, the outer diameter is b, and the pitch is p, and it is wound from a strip metal wire with a rectangular cross section; wherein the length of the rectangular cross section is s=b-a, the width is w, and s / w≥1; the outer surface of the helix 6 is provided with 3 rectangular grooves parallel to the central axis of the helix and evenly distributed; The inner surface is compatible, and the shape of the side surface in contact with the helix 6 is adapted to the shape of the groove on the outer surface of the helix 6, so that the medium clamping rod 2 can fix the helix 6 inside the shell 1 and keep both The central axis is consistent.

[0024] The material of the slow-wave structure helix is molybdenum, the material of the shell is stainless steel, and the material of the clamping rod is beryllium oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com