A conveying device for sending the remaining glass bottles at the bottle outlet of the sterilizing dryer to the filling machine

A conveying device, glass bottle technology, applied in the direction of conveyor objects, transportation and packaging, etc., to avoid pollution, reduce manpower, and ensure cleanliness requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

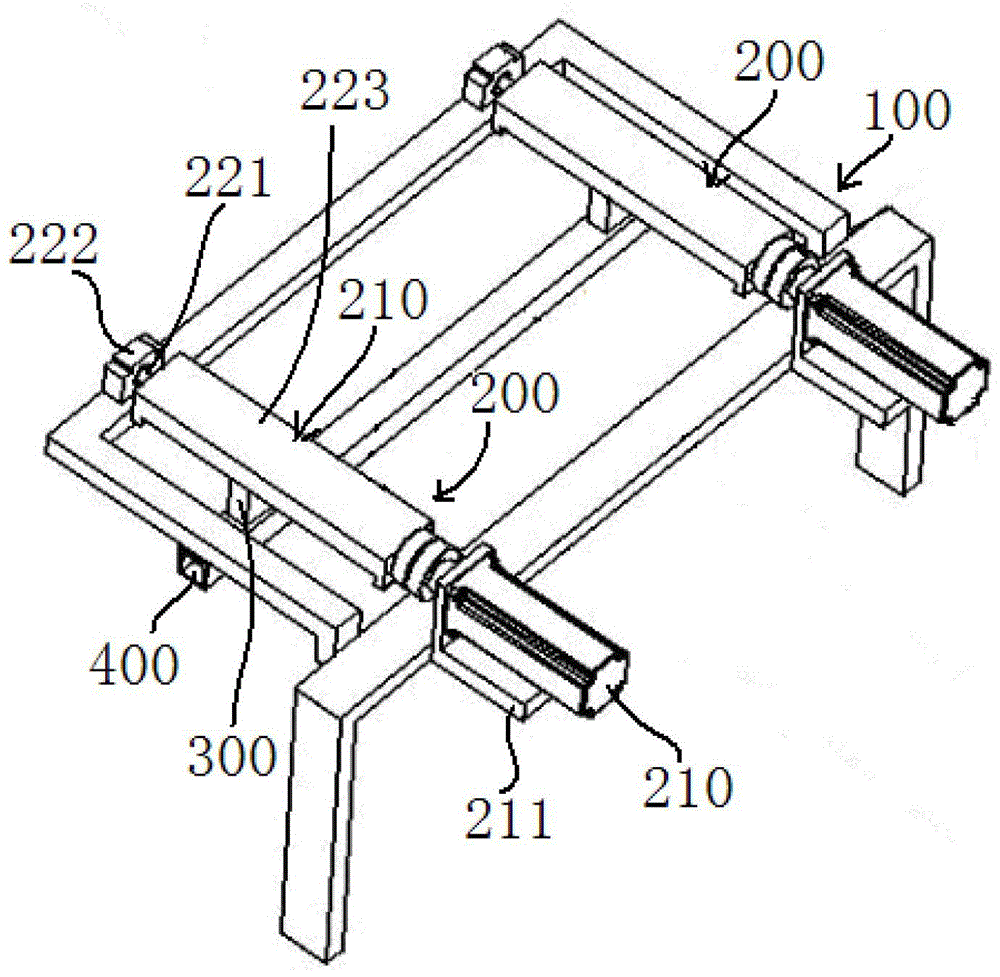

[0018] see figure 1 , the conveying device for sending the remaining glass bottles at the bottle outlet of the sterilizing dryer to the filling machine shown in the figure includes a frame 100, and the frame 100 adopts a frame structure. Two sets of linear drive mechanisms 200 are installed at intervals on the frame 100 .

[0019] The two groups of linear drive mechanisms 200 have the same structure, and both include a motor 210 and a screw slider mechanism. The motor 210 is installed on the frame 100 through a motor bracket 211, and one end of the screw rod 221 in the screw slider mechanism passes through a bearing 222 Supported on the frame 100, the other end of the screw rod 221 is coupled with the output shaft of the motor 210 through a coupling.

[0020] A lifting cylinder 300 is installed on the slide block 223 in the two groups of line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com