Test device for service life of aircraft alternating current generator fuel oil and slide oil radiator

A technology of alternator and life test, which is applied in the testing of machines/structural parts, measuring devices, testing of mechanical parts, etc. It can solve the problems of long time period, small cooling rate of circulating water, small heating rate of oil, etc. Achieve temperature stability, reduce test efficiency, and heat up quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

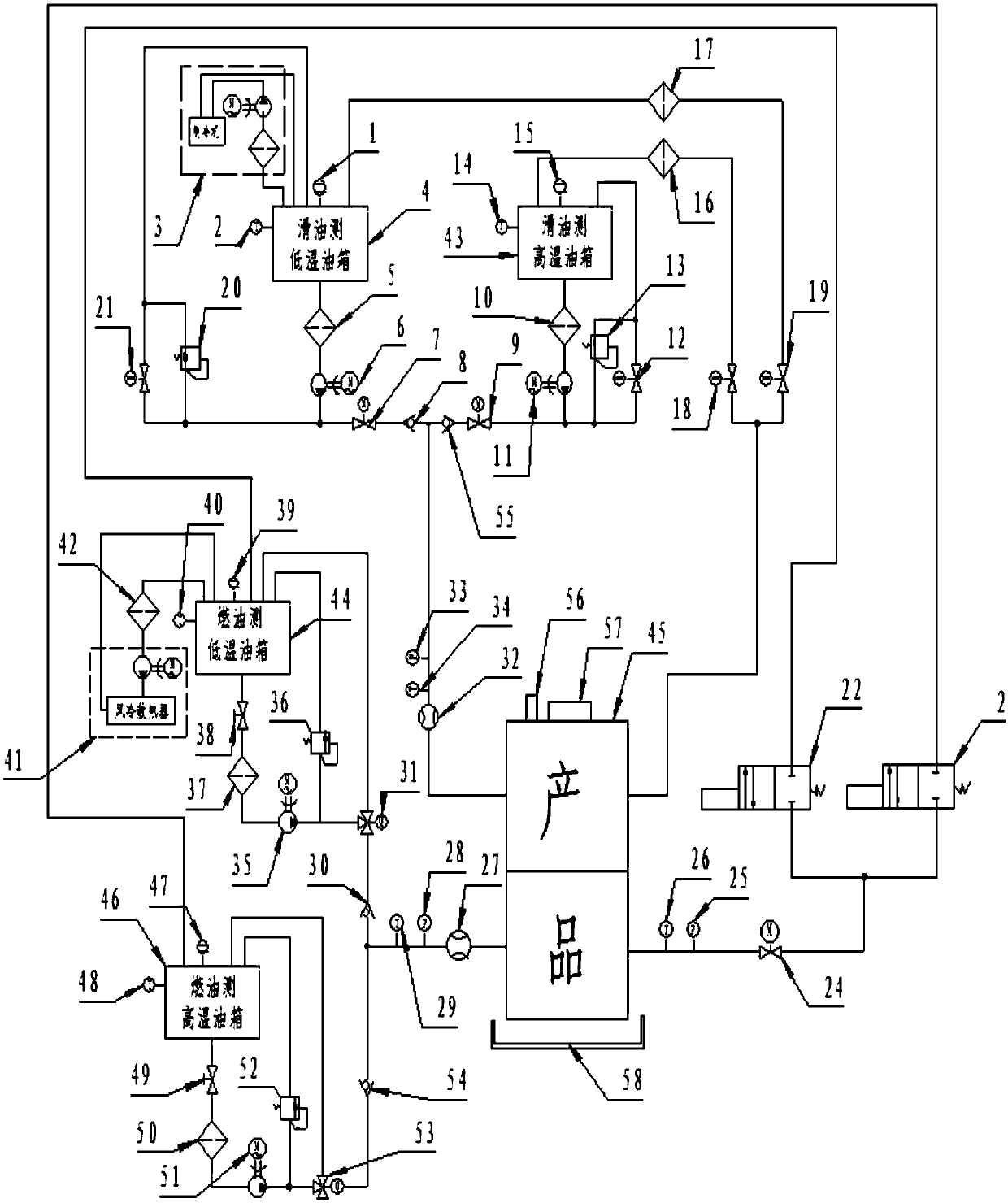

[0027] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0028] The oil mist purification device 57, refrigerator system 3, and air-cooled radiator 41 involved in this embodiment are all existing equipment, as long as their functions meet the requirements. The test software selects labview software, the test system adopts Omron's Ethernet module, the control program is compiled according to the test requirements, and the rest of the test equipment is assembled according to the requirements.

[0029] Such as figure 1 Shown, a kind of aircraft alternator fuel oil radiator life test test device of the present invention, the assembly in the figure comprises the first liquid level sensor 1, the first temperature sensor 2, the refrigerator system 3, the first oil tank 4, the first A filter 5, a first pump 6, a fourth electric valve 7, a first one-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com