Production method of rack steel for self-elevating oil extraction platform

An oil production platform and production method technology, applied in the field of metal materials, can solve the problems of production thickness only reaching 120-150mm, low production efficiency, low yield, etc., and achieve improved welding efficiency, high production efficiency and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

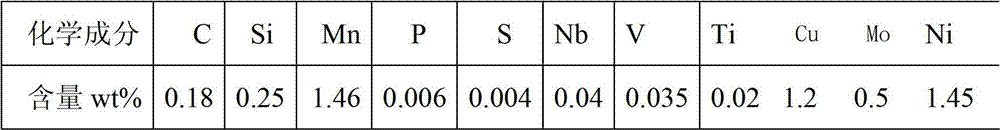

[0030] Embodiment 1: 150mm thick rack steel is produced by a combined welding process of gas shielded welding, submerged arc welding and vacuum electron beam welding:

[0031] 1) High-purity molten steel is smelted. After the molten steel is smelted in a converter, LF+RH double refining is carried out. RH vacuum treatment maintains a vacuum degree of 100Pa for 11 minutes. After refining, the molten steel gas contains [O] 12ppm, [H] 2ppm.

[0032] 2) The continuous casting process of molten steel adopts full protection pouring, and uses electromagnetic stirring to pour at a constant speed. The thickness of the continuous casting slab produced is 250mm, and the analysis results of the smelting composition are as follows:

[0033] Table 1 Example 1 Continuous Casting Slab Chemical Composition

[0034]

[0035]3) Process the three sides of the two produced 250mm thick continuous casting slabs to be welded by the flame cutting method. The groove depth is 25mm and the groove ang...

Embodiment 2

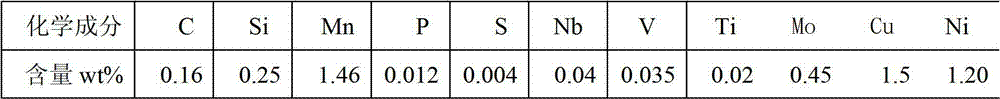

[0046] Example 2: Production of 150mm thick rack steel by full vacuum electron beam welding:

[0047] 1) High-purity molten steel is smelted. After the molten steel is smelted in a converter, LF+RH double refining is carried out. RH vacuum treatment maintains a vacuum degree of 100Pa for 11 minutes. After refining, the molten steel gas contains [O] 12ppm, [H] 2ppm.

[0048] 2) The continuous casting process of molten steel adopts full protection pouring, and uses electromagnetic stirring to pour at a constant speed. The thickness of the continuous casting slab produced is 250mm, and the analysis results of the smelting composition are as follows:

[0049] Table 2 Example 2 Continuous Casting Slab Chemical Composition

[0050]

[0051] 3) Process the produced two 250mm thick continuous casting slabs with a milling machine to remove surface oxide scales, oil stains, etc., and process the two slabs into the same size.

[0052] 4) After the processed blanks are stacked togeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com