Detection method for impurities in receiver drier

A technology of a liquid storage dryer and a detection method, which is applied in the field of impurity detection of liquid storage dryers, can solve the problems of pouring out, cannot detect the content of impurities, and cannot be operated, and achieves the effects of avoiding blockage, requiring accurate cleanliness, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

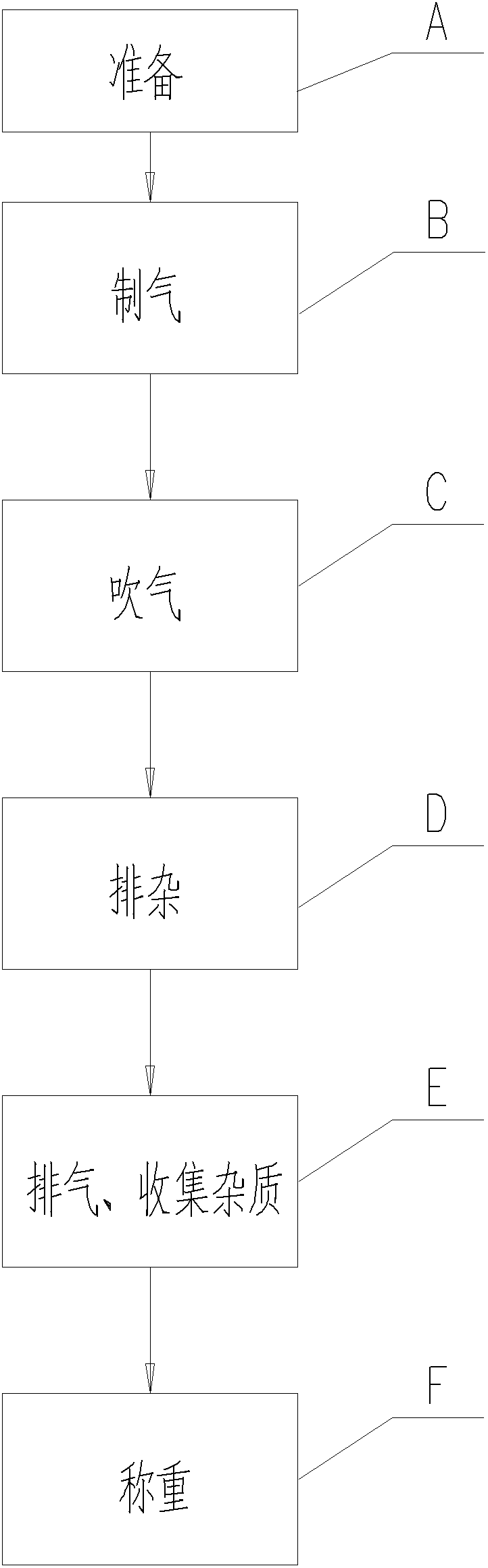

[0035] A method for detecting impurities in a storage drier, the method comprising the following steps (see figure 1 shown in the flowchart):

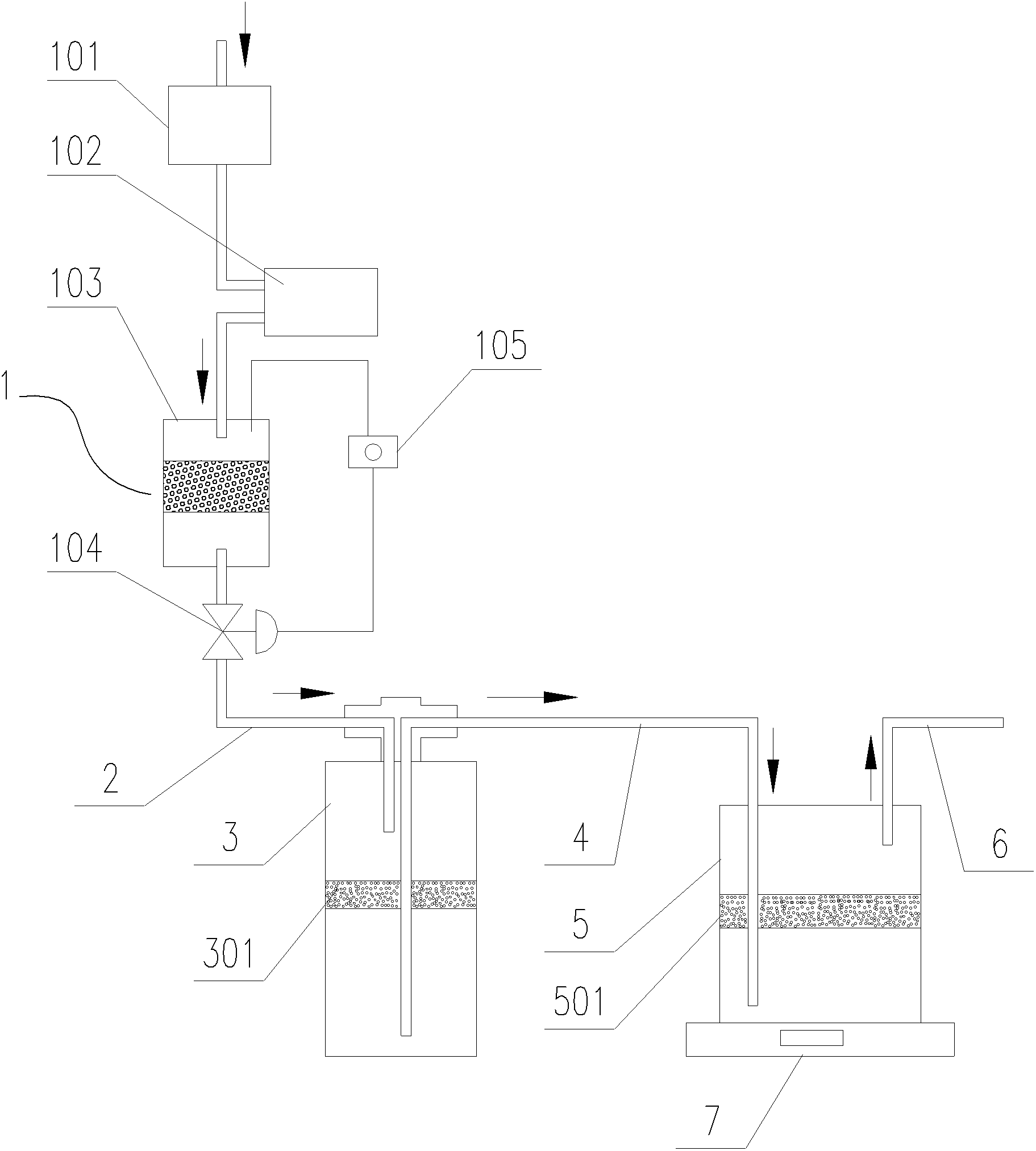

[0036] A. Preparation: Prepare the impurity detection device of the liquid storage drier including the gas production device 1, the liquid storage drier 3, the impurity collector 5 and the weighing device 7, and connect the output end of the gas production device 1 to the storage liquid with the pipeline A2 The top of the filter layer 301 in the drier is connected, the bottom of the filter layer 301 in the liquid storage drier is connected with the bottom of the filter layer 501 in the impurity collector with the pipeline B4, and the top of the filter layer 501 in the impurity collector is connected with the pipeline C6. The outside world is communicated, and then the impurity collector 5 is placed on the weighing device 7 (see image 3 ).

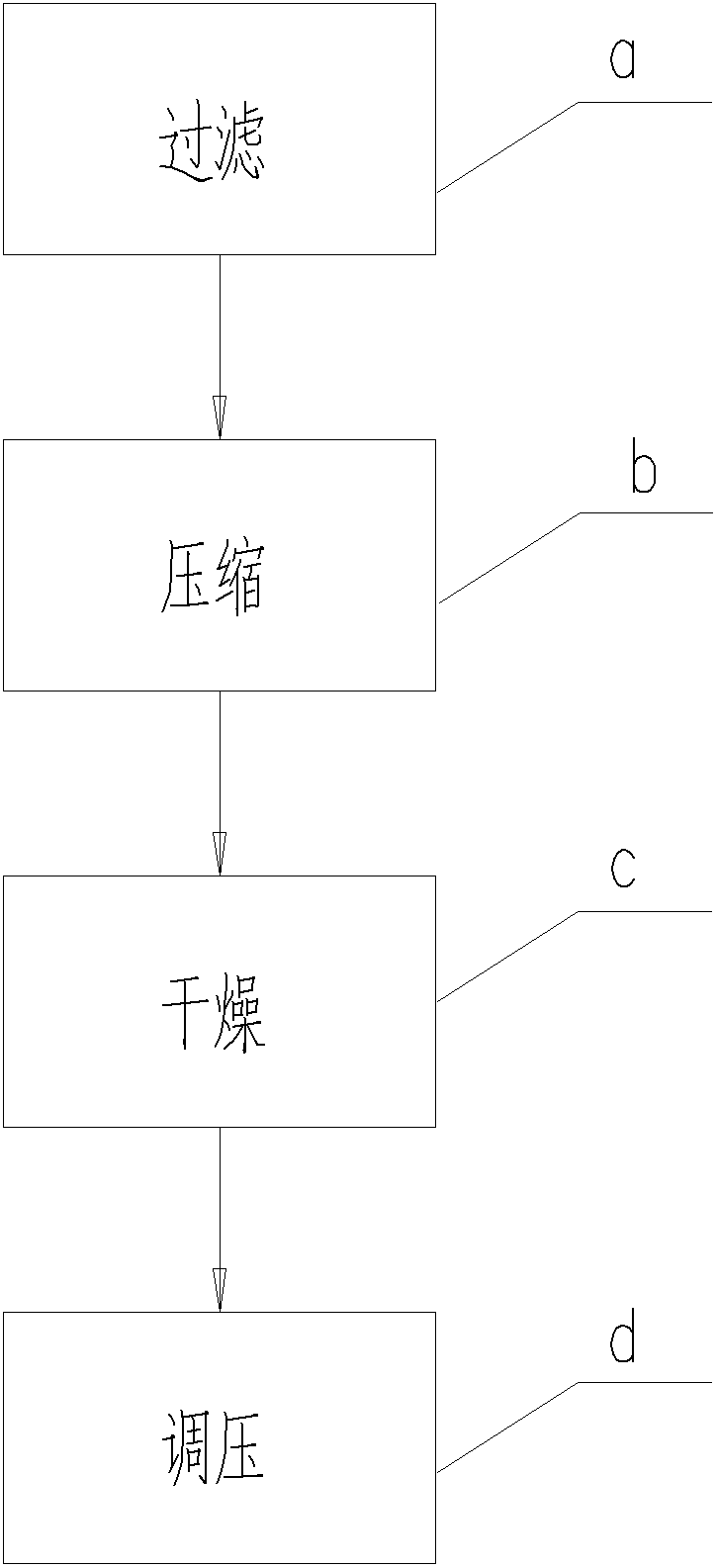

[0037] B. Gas production: produce clean compressed dry gas with a pressure of 1.0Mpa through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com