Full-automatic cleaning oil-coating device

A fully automatic cleaning and oiling technology, applied in coatings, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of not being able to achieve fully automatic, high-efficiency cleaning and anti-rust effects, and improve reuse High efficiency, guaranteed cleanliness requirements, convenient opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

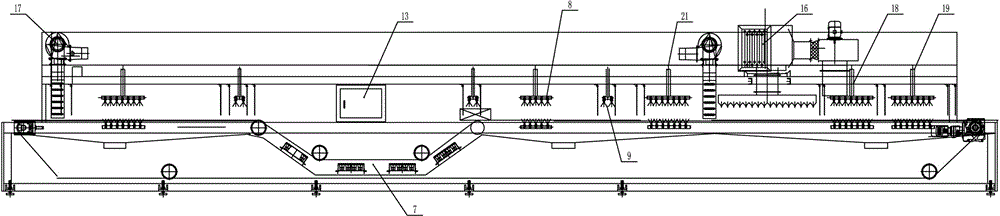

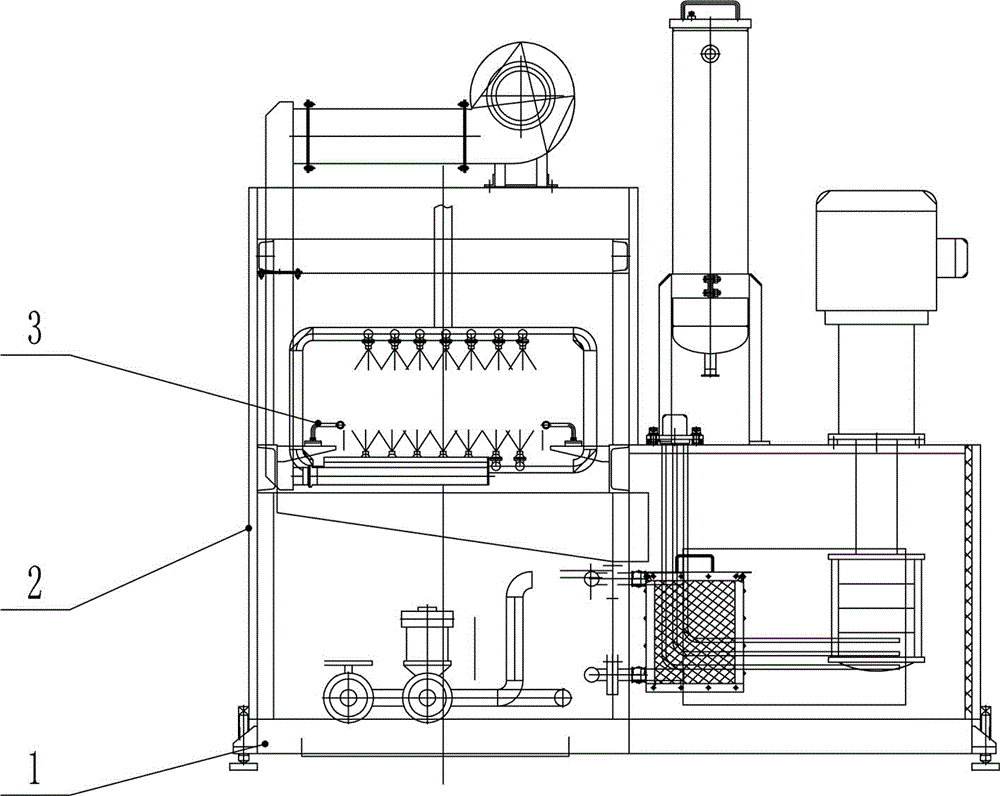

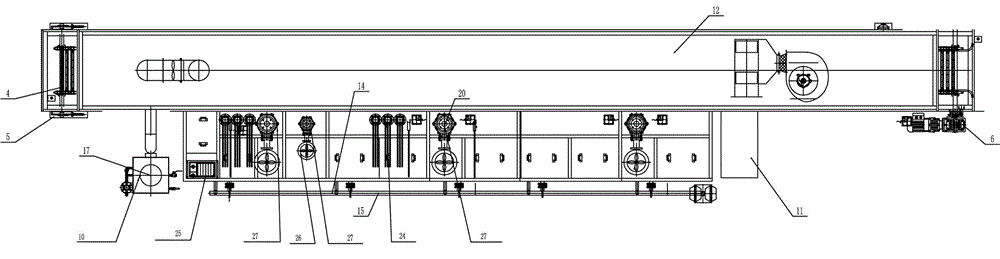

[0014] See attached Figure 1-3 As shown, a fully automatic cleaning and oiling equipment, which includes a machine base 1, a frame 2 and an electrical control device 12 are arranged on the machine base, guide rails 3 and stainless steel conveyor chains 4 are arranged on the top of the frame, and stainless steel conveyor chains It has a mesh belt chain tensioning device 5 and a chain stepless speed regulation conveying system 6. The upper part of the stainless steel conveying mesh chain is provided with a sealing cover 13, and the sealing cover is sequentially provided with a spray cleaning device 22, a first water cutting air knife 23, an ultrasonic Cleaning system 7, second water cutting air knife 9, spray rinsing device 8, third water cutting air knife 10, compressed air blowing device 21, wind drying system 16, oiling device 18 and deoiling device 19, machine There is a cleaning fluid filtration system on the side of the rack.

[0015] Preferably, the cleaning and oiling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com