Intelligent efficient high-pressure cleaning machine

A high-pressure cleaner and washing machine technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of low cleaning accuracy, inability to meet multiple varieties and specifications of products, and poor positioning effect. Achieve the requirements of ensuring cleanliness, improve the reuse rate, and prevent the mist from escaping the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

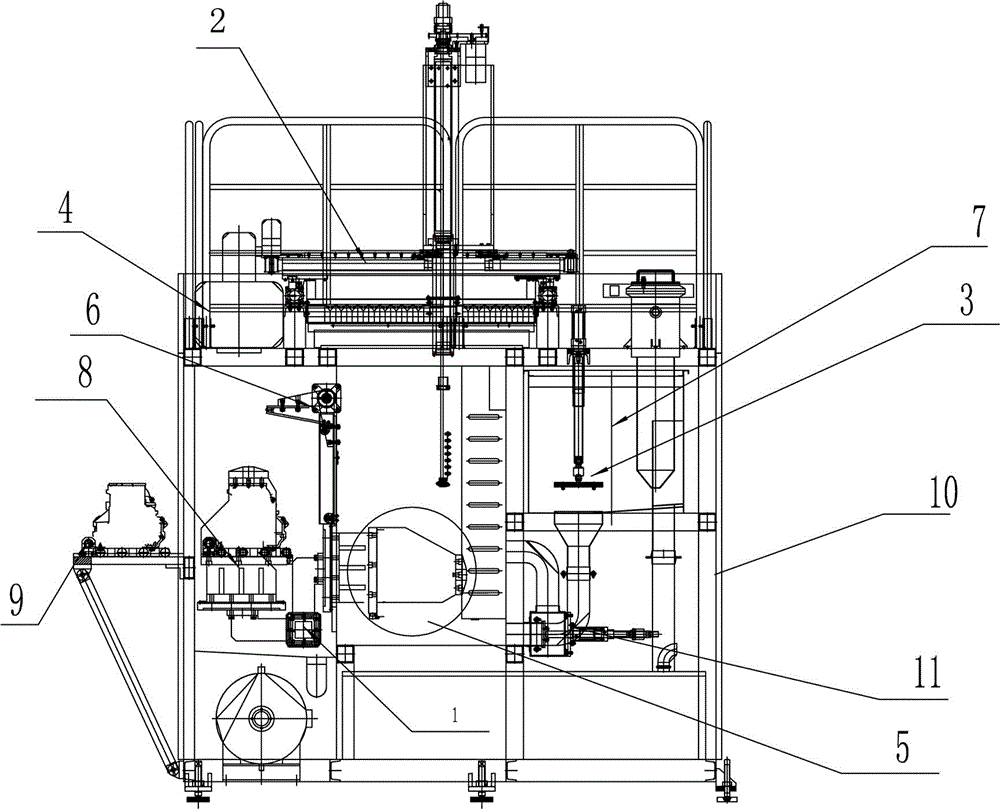

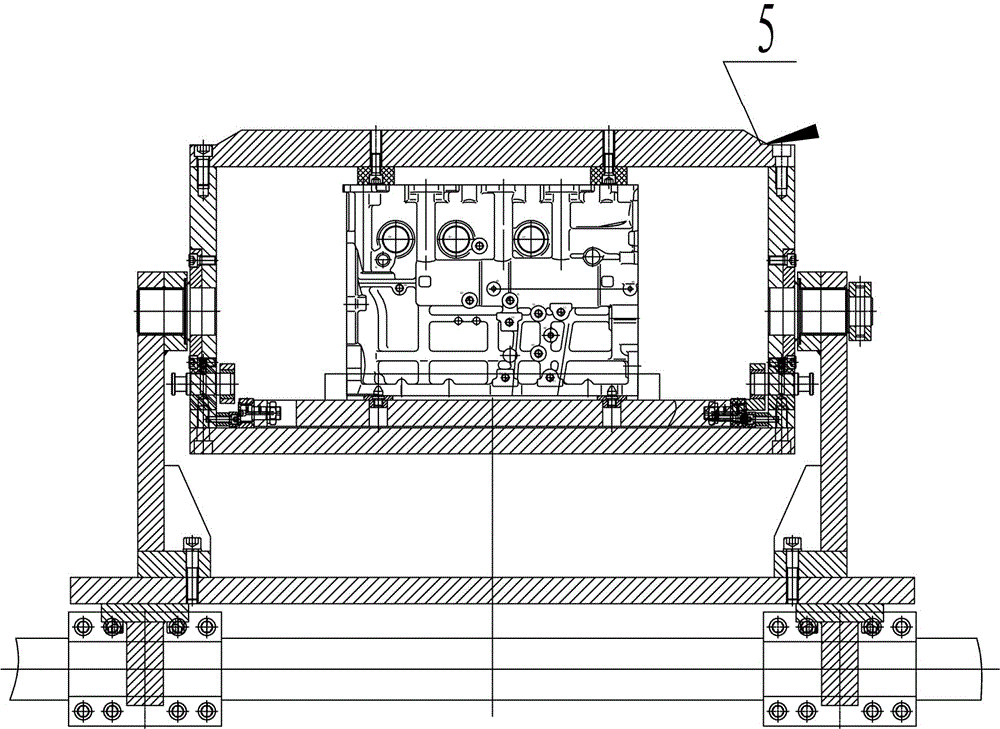

[0012] See attached Figure 1-2 As shown, an intelligent high-efficiency high-pressure cleaning machine includes a skeleton 10 and an electrical control system. The outer side of the skeleton is provided with a workpiece tray 9, and the upper end of the skeleton is provided with a manipulator system 2. Below the manipulator system is a cleaning room. There is a turning mechanism 1 and a washing room water retaining door 6. The turning mechanism is equipped with a turning cage 5 and a workpiece fixture 8. The turning mechanism turns the workpiece into the cleaning room through the washing room water retaining door. A water storage tank 7 is provided on the outside of the cleaning room. There is a surge control mechanism 3 inside, a cleaning chamber water discharge device 11 is provided outside the bottom of the cleaning chamber, and an imported mist exhaust system 4 is provided above the cleaning chamber. The electrical control system is used for automatic control of the cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com