Bag filling, clamping and expanding mechanism with automatic bag loading function

A bag expanding mechanism and clamping technology, applied in packaging and other directions, can solve the problems of small clamping force, complex clamping mechanism structure and high failure rate, and achieve the effect of improving the clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

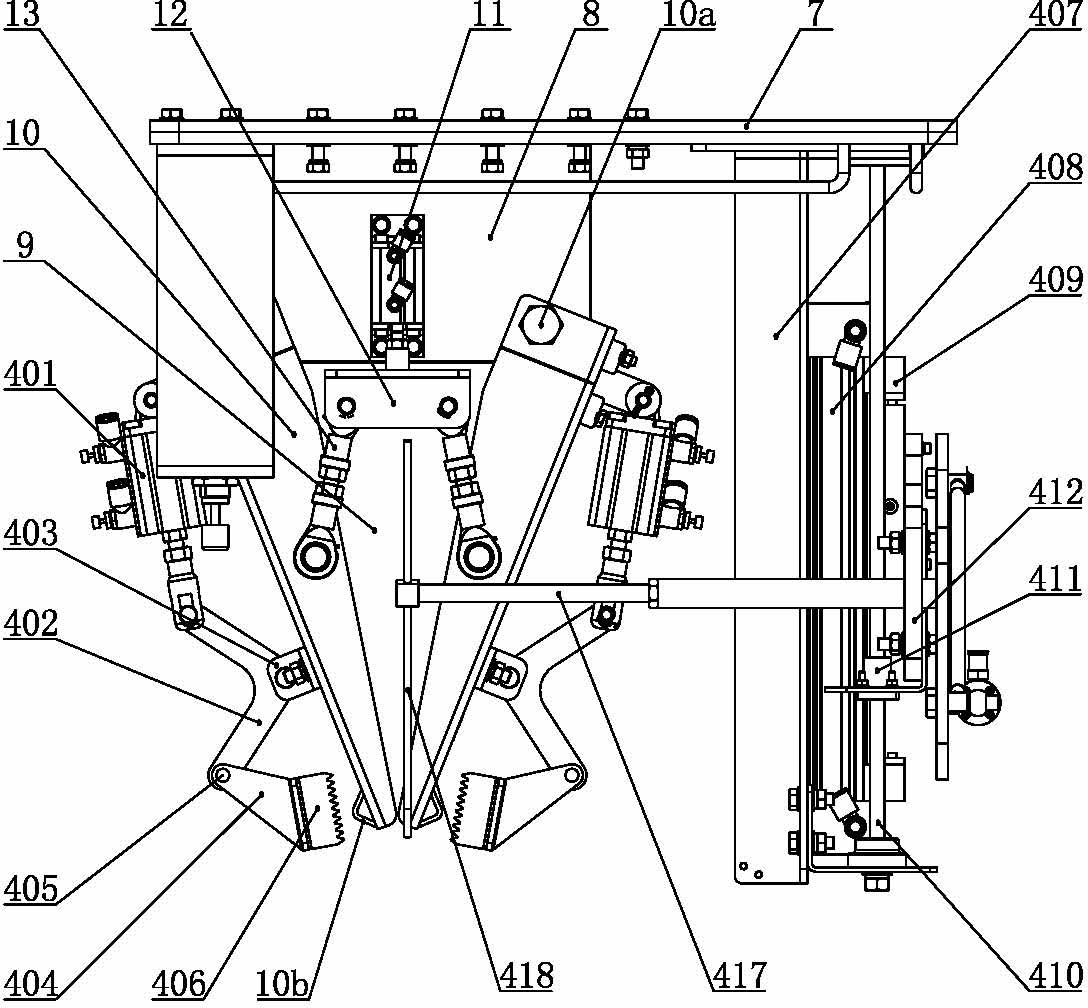

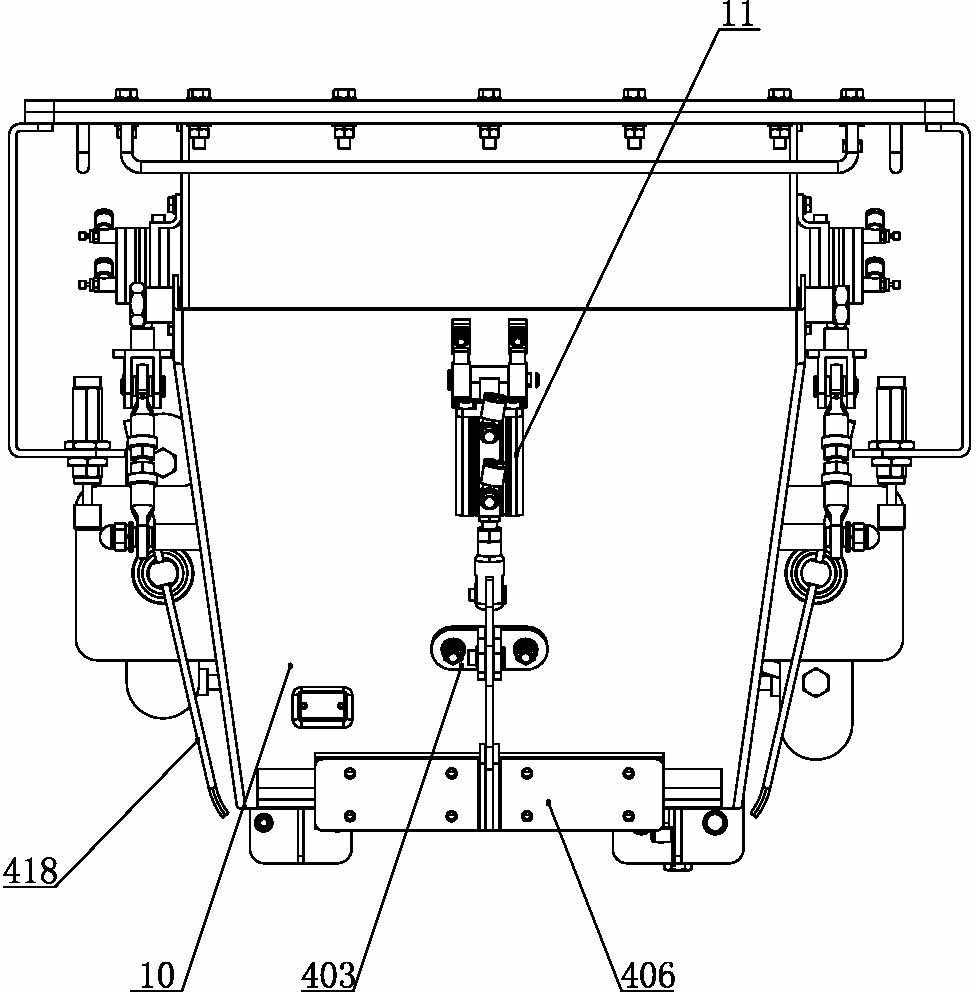

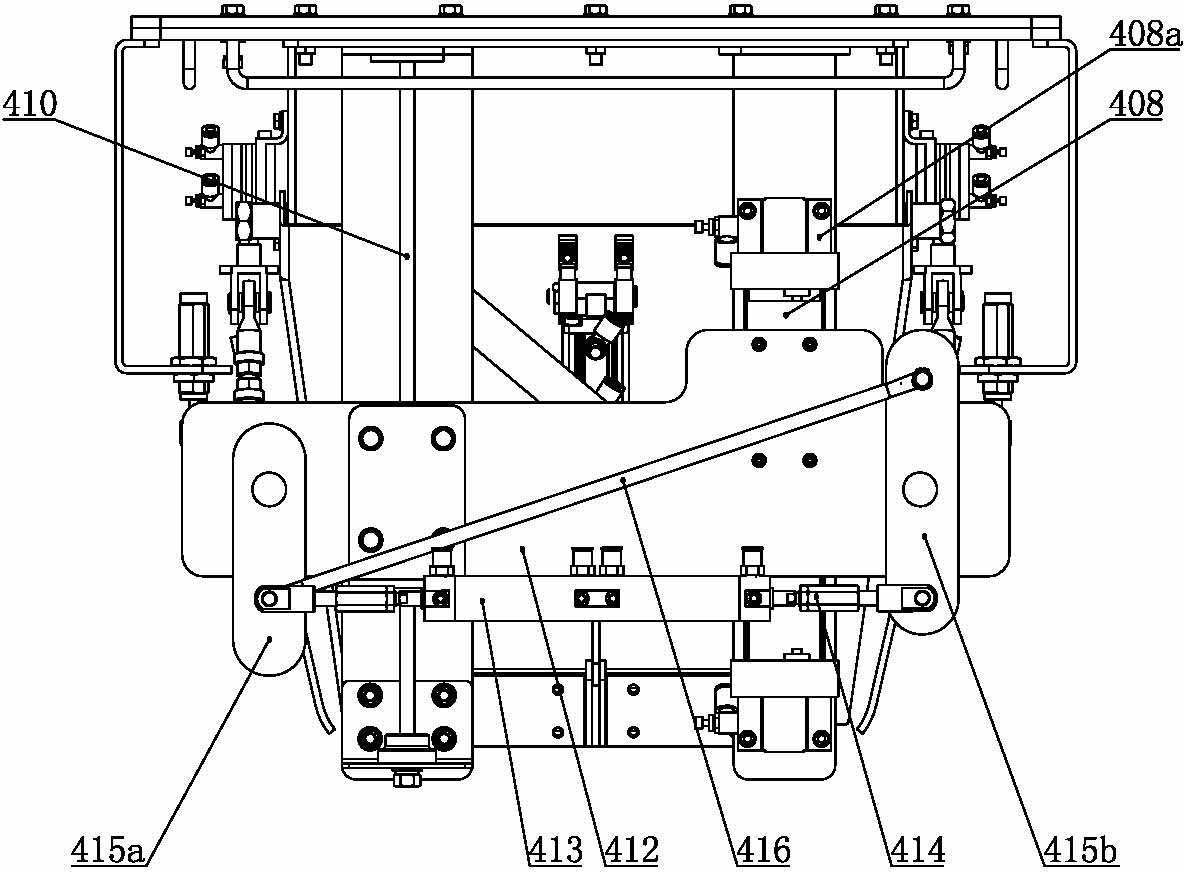

[0018] Such as Figure 1 to Figure 4 As shown, in the clamping and expanding bag mechanism for automatic bagging of the present invention, the blanking cylinder 8 is fixed below the blanking cylinder installation platform 7, and the front and rear sides of the lower port of the blanking cylinder are respectively provided with V-shaped blanking fixing plates 9, V The left and right sides of the shaped blanking fixed plate 9 are respectively provided with a blanking duckbill plate 10 which can be closed, and the upper ends of the blanking duckbill plate 10 are respectively hinged on the blanking barrel 8 through the blanking duckbill plate hinge seat 10a. The upper ends of the two V-shaped blanking fixed plates 9 are respectively fixed with vertically arranged blanking cylinders 11, the lower ends of the piston rods of the blanking cylinders 11 are respectively hinged with the middle part of the blanking connection pair 12, and the blanking connection pair 12 is horizontally arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com