Improved piston-type control valve

A control valve and piston-type technology, which is applied in the field of improving piston-type control valves, can solve the problems affecting the service life of the valve body and the damage of communication holes, etc., and achieve the effects of compact structure, reduced number of parts, and reduced noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, the present invention will be further described with reference to the accompanying drawings and specific implementations, so as to more clearly understand the technical ideas claimed by the present invention.

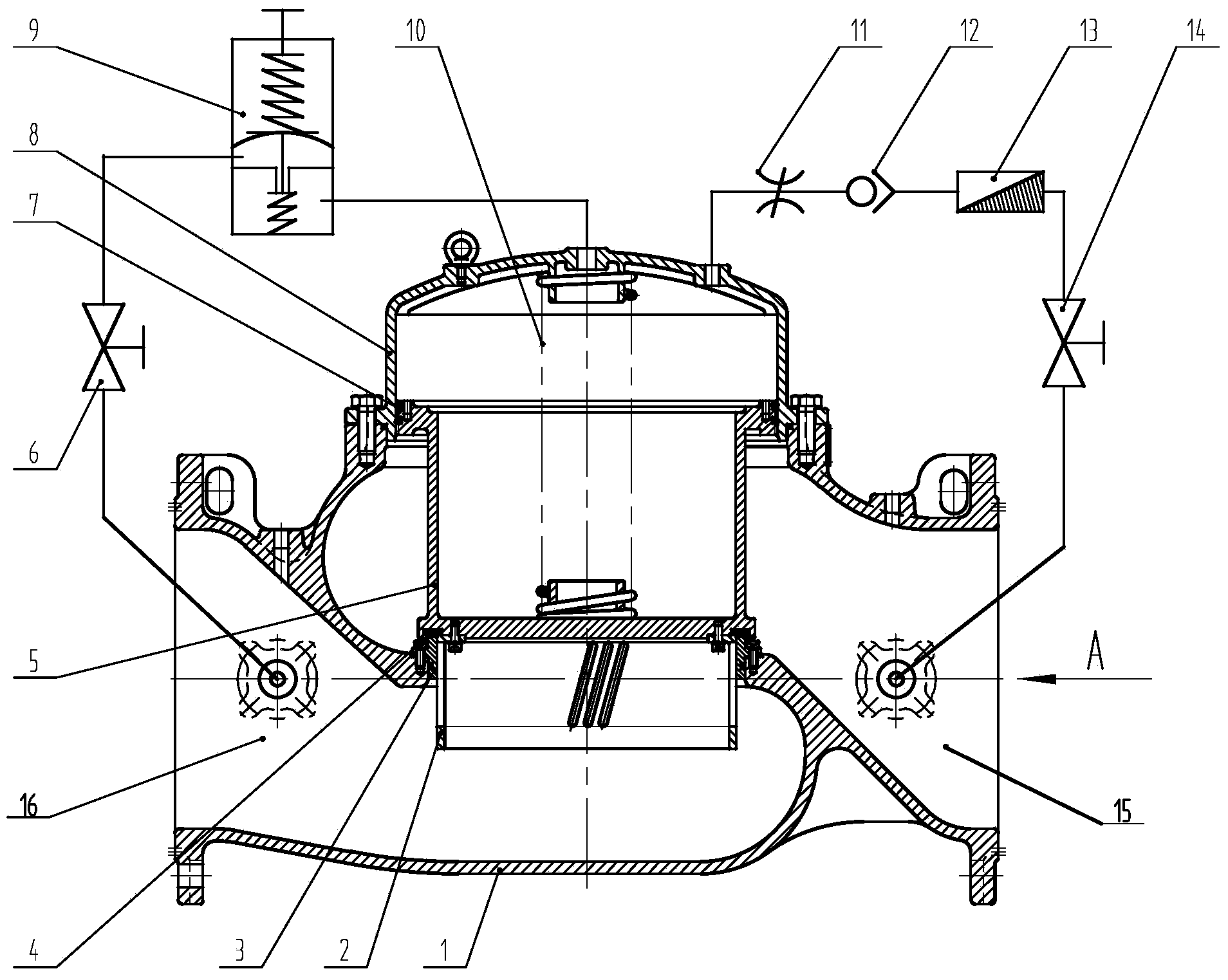

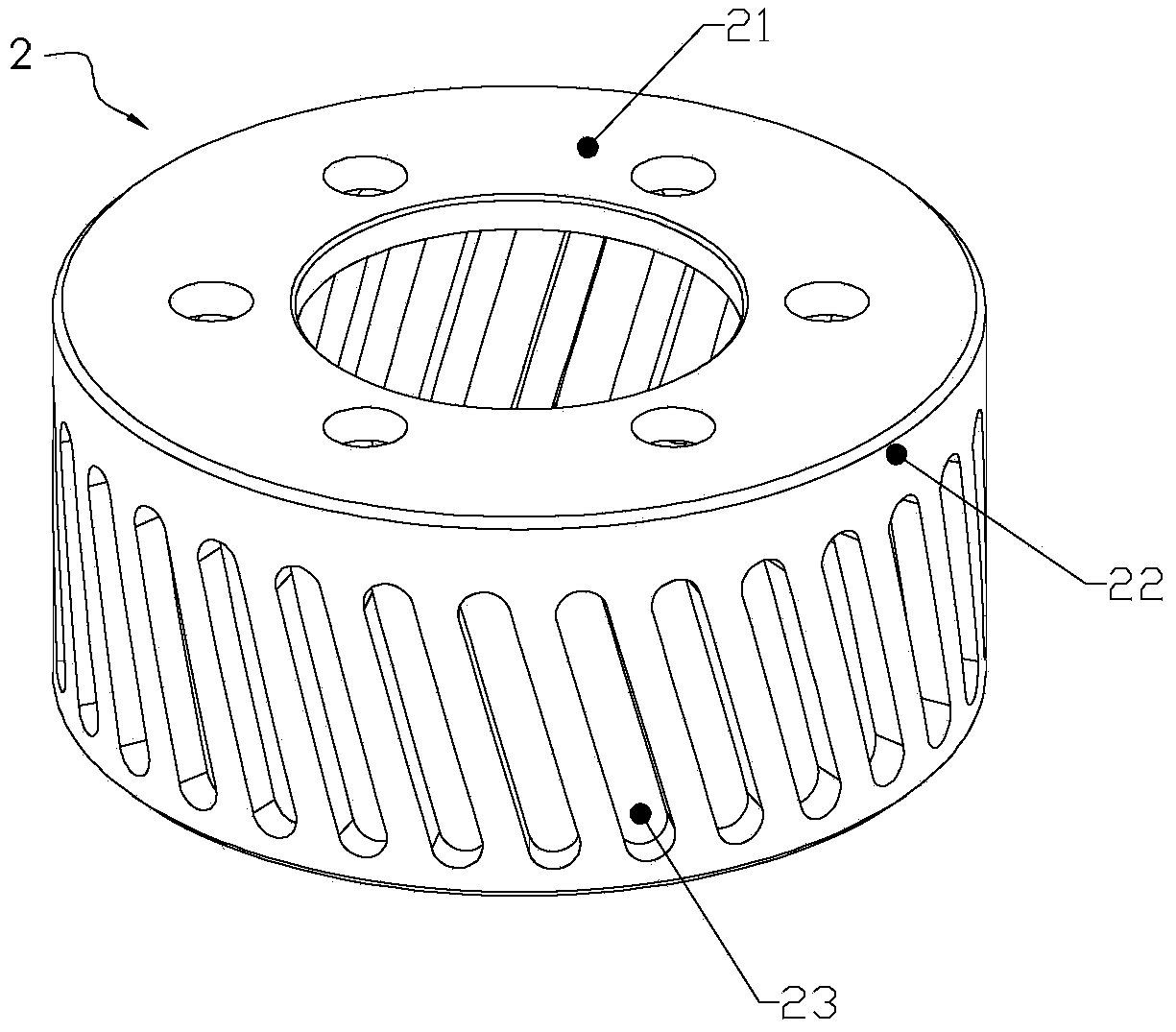

[0021] Such as figure 1 , 2 Shown here is an improved piston control valve of the present invention, including a valve body 1, a piston cylinder 8, a piston 5, and a spring 10 mounted on the valve body 1; the valve body 1 is formed with a liquid inlet channel 15 and The liquid outlet channel 16 is provided with a communication hole between the liquid inlet channel 15 and the liquid outlet channel 16; the upper end of the piston 5 and the piston cylinder 8 are dynamically sealed and matched, and the piston 5 and the piston cylinder 8 cooperate to form a movable cavity The piston 5 can move between the closed position that blocks the opening of the upper end of the communicating hole and the open position away from the communicating hole; the spring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com