Ball valve

A technology for ball valves and spherical valve bodies, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., which can solve the problems of inflexible opening and closing of ball valves, leakage service life, etc. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

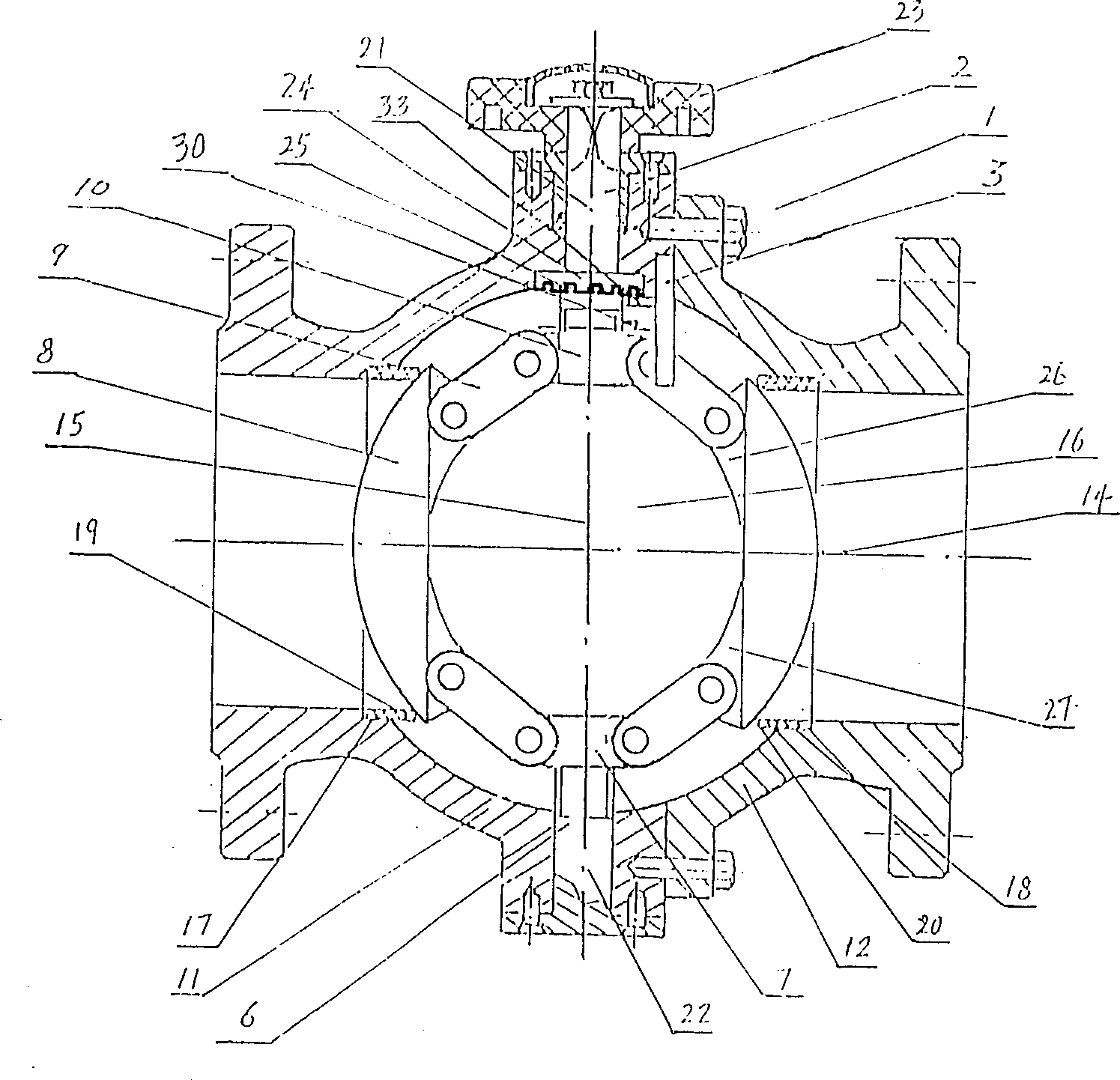

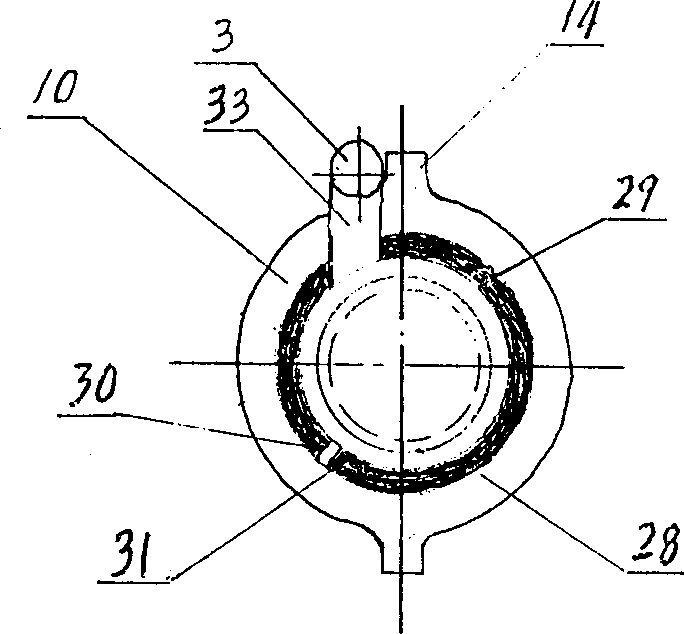

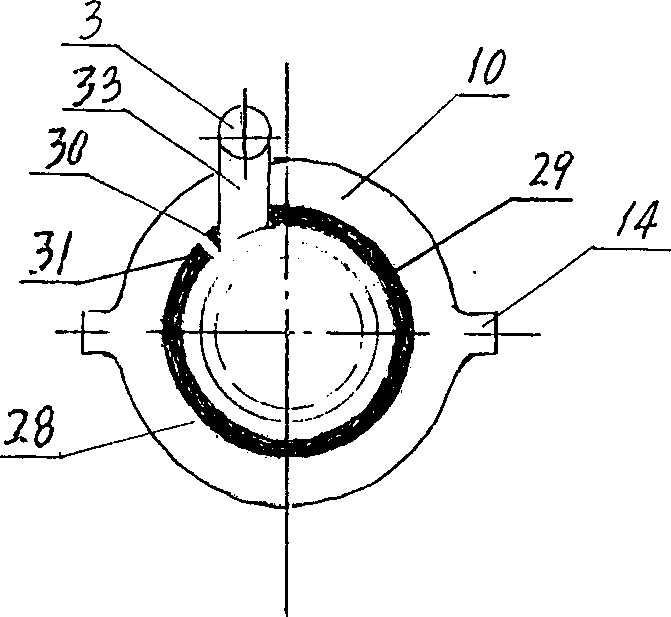

[0009] Specific embodiments of the ball valve of the present invention will be described in detail below with reference to the accompanying drawings.

[0010] Such as figure 1 As shown, the ball valve of the present invention has two substantially hemispherical half shells 11 and 12, which are fixedly connected by bolts to form a hollow spherical valve body 1.

[0011] The spherical valve body 1 has a horizontal central channel 14 , a vertical central hole 15 from top to bottom and a valve chamber 16 .

[0012] The two half-shells 11 and 12 respectively have annular valve seats 17 and 18 on the horizontal central channel of the spherical valve body 1, on which a sealing member 19 and 20 is mounted respectively.

[0013] The vertical central hole 15 includes a vertical central hole 21 at the top of the spherical valve body 1 and a vertical central hole 22 at the bottom of the spherical valve body 1 .

[0014] A valve stem 2 is rotatably installed in the vertical central hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com