Valve shaft sealing device

A sealing device and valve shaft technology, applied in shaft sealing, valve device, valve details and other directions, can solve the problems of pipeline pressure rise, pipeline circulation medium leakage, etc., to achieve small valve opening and closing torque, good sealing performance, and contact area. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

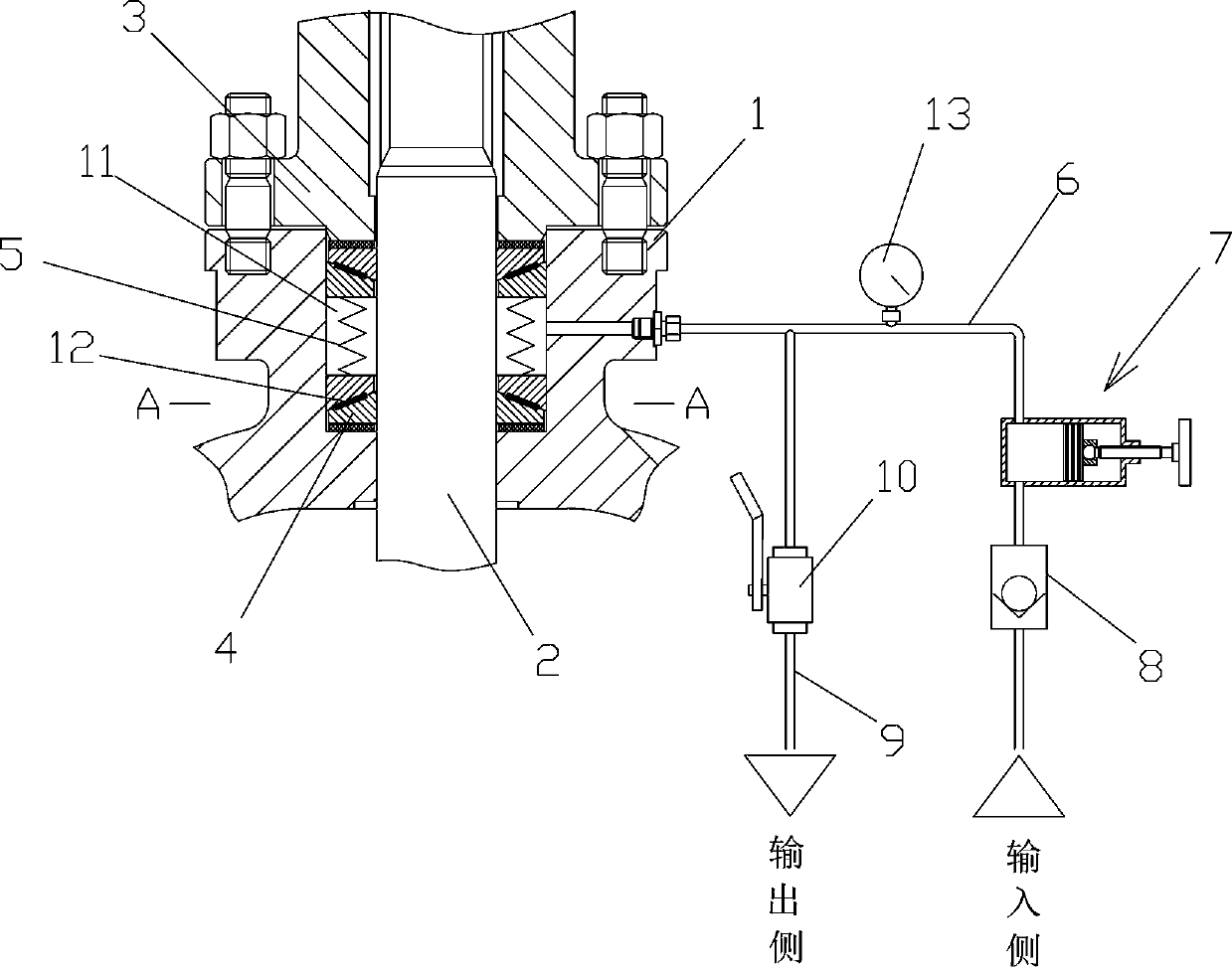

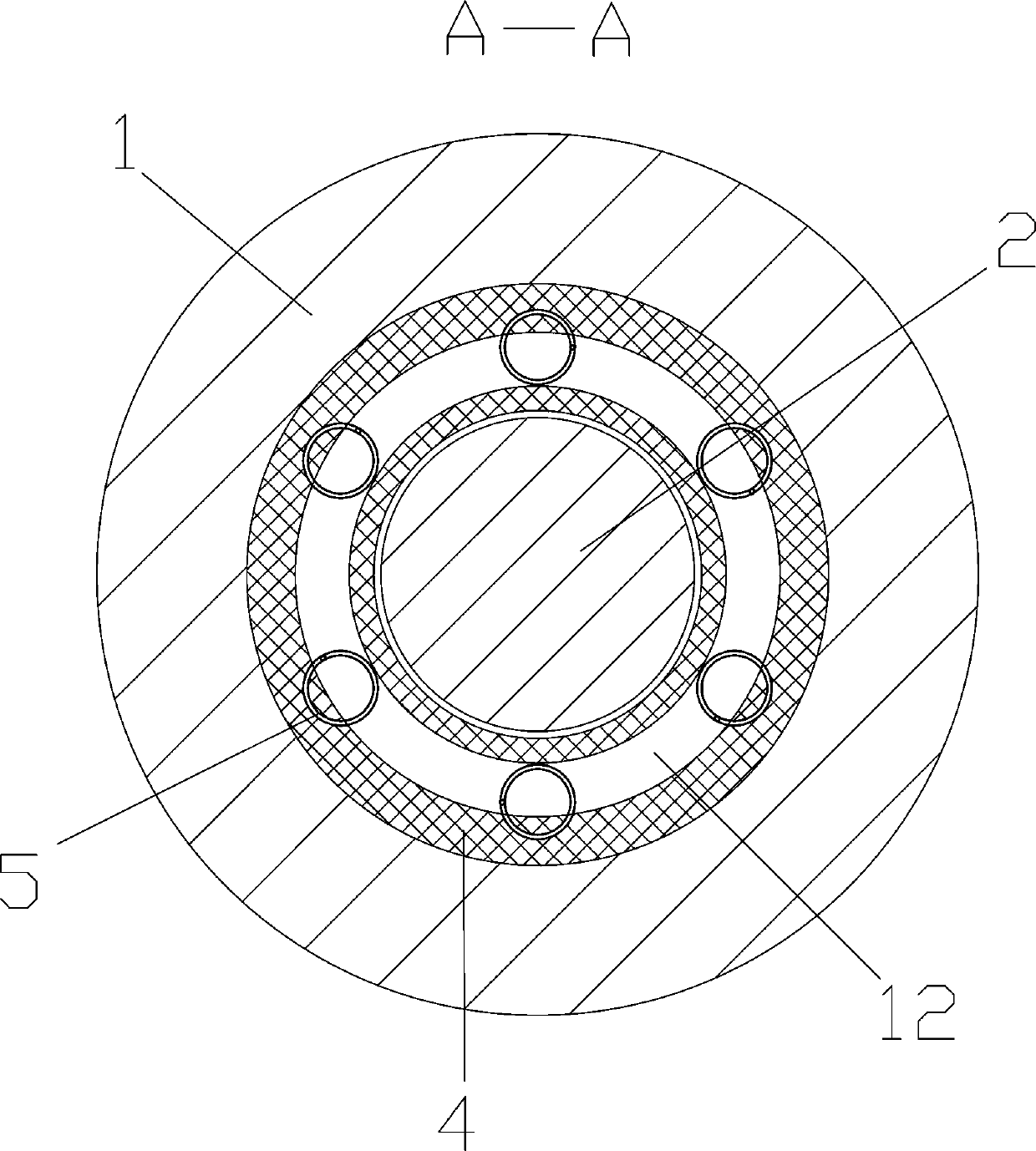

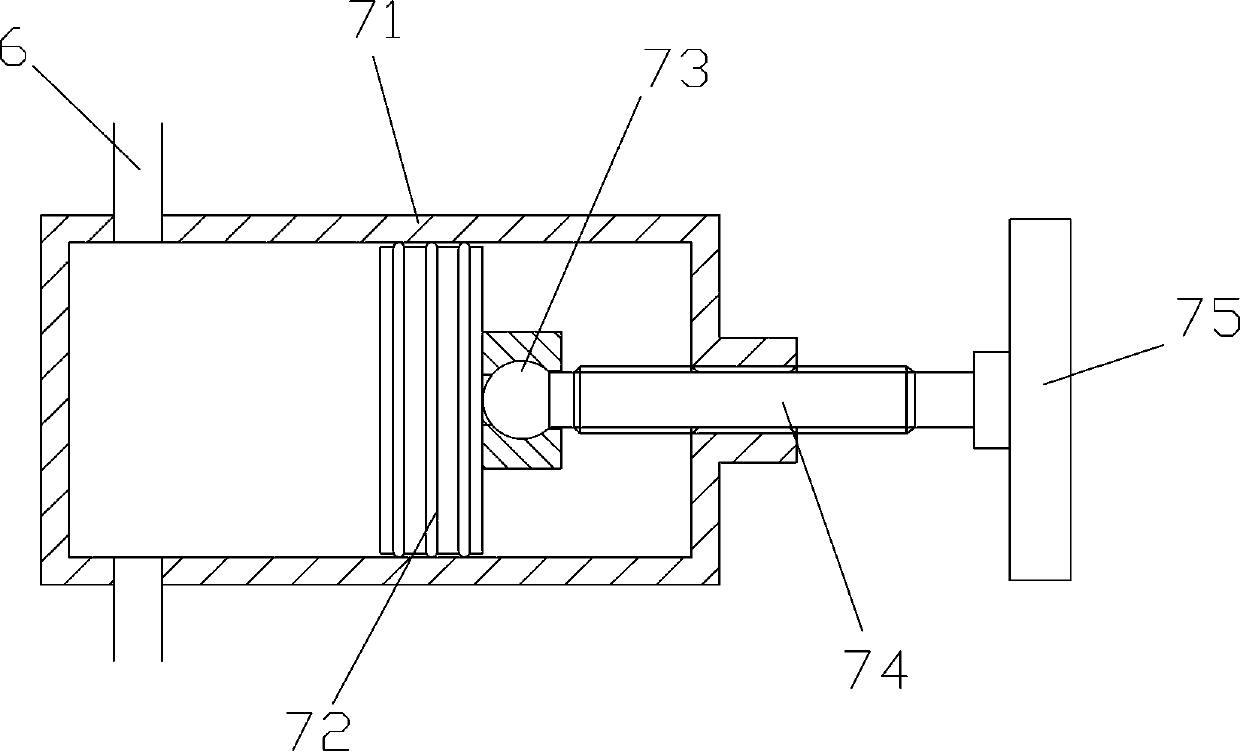

[0014] Such as figure 1 with 2 As shown, a valve shaft sealing device includes a valve body 1, a valve shaft 2 and a gland 3, an annular groove 11 is arranged in the valve body 1 around the valve shaft 2, and the gland 3 seals the upper opening of the groove 11 , There are two sets of expansion assemblies in the slot 11, the two sets of expansion assemblies pass through a plurality of springs 5, and each spring 5 is evenly distributed around the axis of the valve shaft 2, and the springs 5 push the two sets of expansion assemblies against the gland 3 and the The bottom surface of the cut groove 11, the cut groove 11 is connected to the input end of the valve body 1 through the liquid inlet pipe 6; the expansion assembly includes two rubber rings 4, and the end faces of the two rubber rings 4 in contact with each other are inclined surfaces.

[0015] The working principle of the present invention is: when the pressure of the pipeline where the valve is installed is at normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com