Brake vale

A gate valve and valve stem technology, applied in the field of valves, can solve the problems of large opening and closing torque of the valve, easy damage to the sealing ring, and inability to automatically adjust the compression ratio, so as to reduce the opening and closing torque of the valve, prolong the life of parts, and facilitate disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

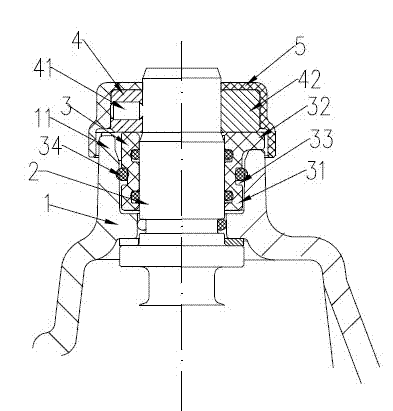

[0018] like figure 1 As shown, the gate valve provided by the present invention includes four parts: a bonnet 1, a valve stem 2 in the bonnet 1, a valve stem envelope 3 nested between the bonnet 1 and the valve stem 2, and a sealing dustproof Functional sealing mechanism4. The valve stem cover 3 is divided into two parts: a sleeve body 31 and a stepped portion 32. The sleeve body 31 of the valve stem cover 3 is a hollow cylinder, and the thickness of the sleeve body 31 is slightly smaller than the distance between the valve stem 2 and the valve stem cover. The body 31 is located between the valve stem 2 and the valve cover 1 . The stepped portion 32 is located at the top of the sleeve body 31 , and the stepped portion 32 is integrated with the sleeve body 31 . The step portion 32 and the sleeve body 31 form rounded corners, which can better make the step portion 32 fit t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com