Ceramic slide valve

A technology of ceramic valve seat and ceramic valve core, which is applied in the direction of sliding valves, valve devices, engine components, etc., can solve problems such as poor sealing performance, flow channel erosion, and damage to the sealing surface of valve seats, so as to improve processing technology, Avoid erosion and cavitation and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

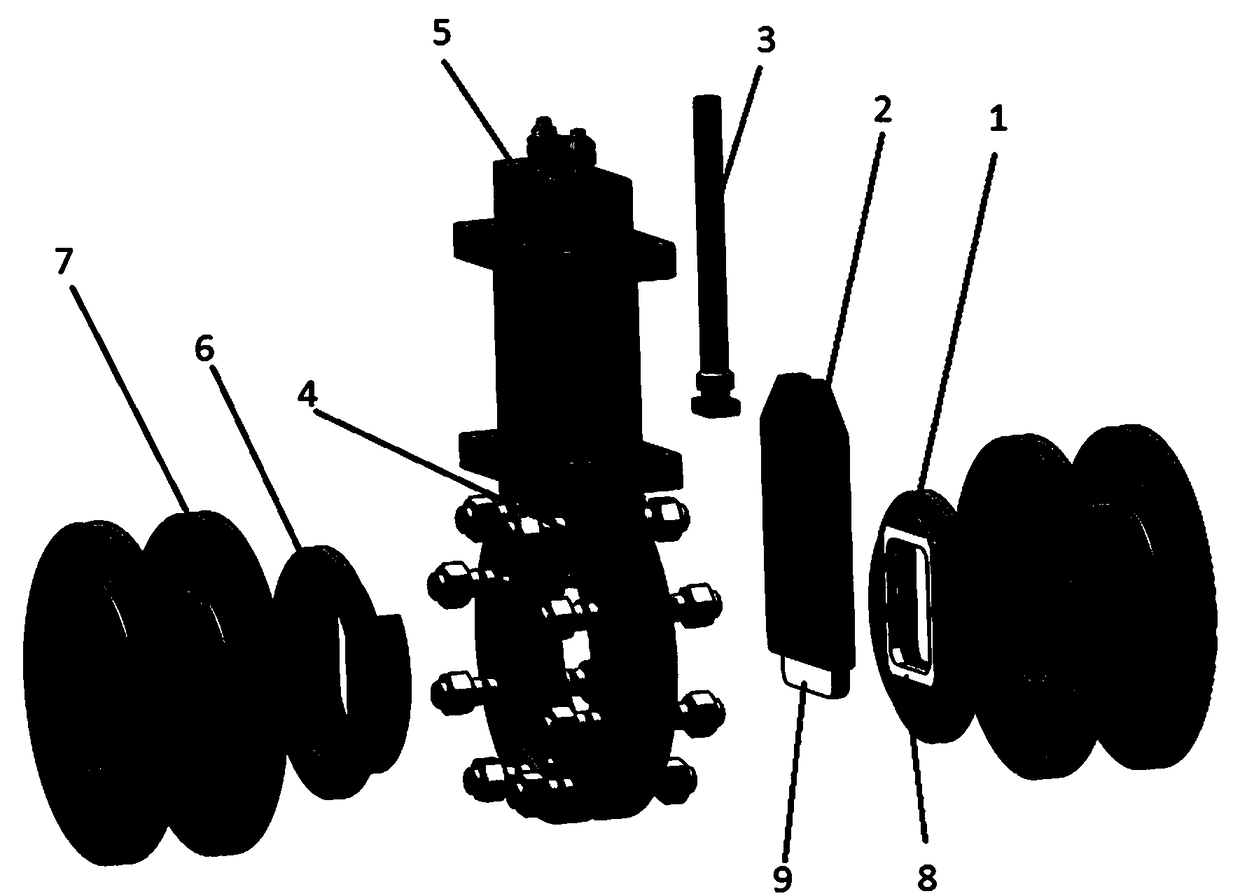

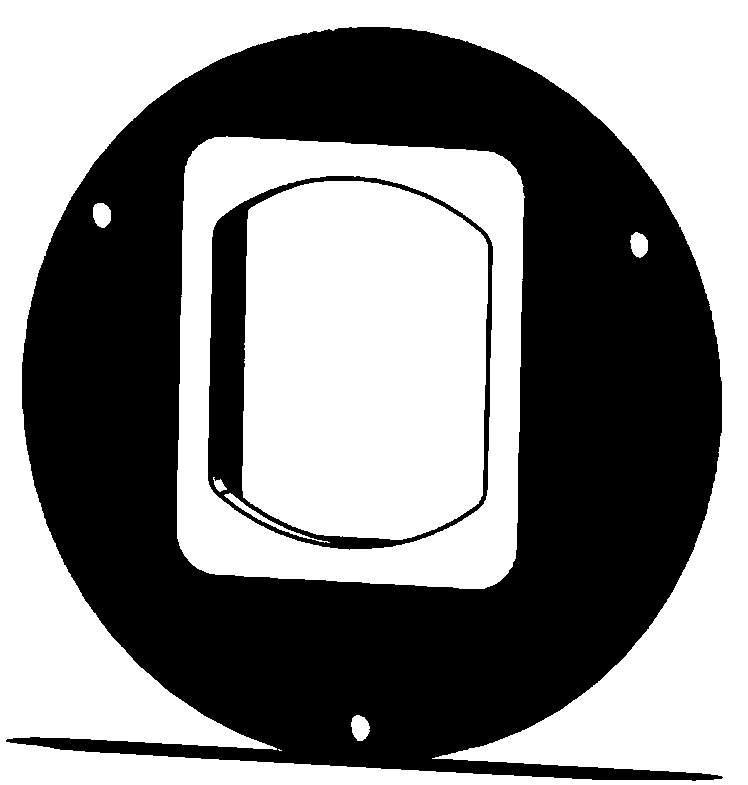

[0030] Such as figure 1 As shown, a ceramic slide valve includes a disc valve seat 1 and a slider 2, a valve stem 3, a valve body 4, an upper platform 5, a valve inner lining 6, and a flange 7; There is a valve inner lining 6; the lower end of the valve stem 3 is connected with the upper end of the slider 2; Moving up and down, it forms a plane seal with the edge of the flow channel hole of the disc valve seat 1, and realizes throttling, opening and closing of the fluid.

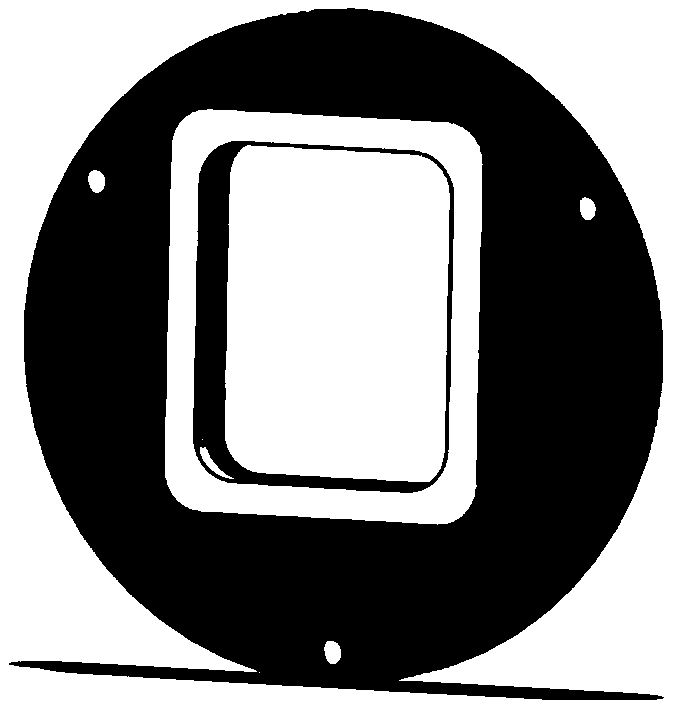

[0031] The disc valve seat 1 is in the shape of a disc and is fixed on the valve body 4 . The disc valve seat 1 adopts metal inlaid ceramic valve seat 8, and the edge of the flow channel hole and the main sealing surface of the disc valve seat 1 are all made of structural ceramic materials.

[0032] The combination of ceramic and metal is mechanical locking, gluing or mechanical gluing combination; the sealing surface of the flow channel hole is made of ceramic wear-resistant material.

[0033] The up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com