Multi-purpose self-return positioning door shaft

An automatic return and multi-purpose technology, which is applied in door/window accessories, switches with braking devices, buildings, etc., can solve the problem that the hydraulic oil viscosity of the floor spring is greatly affected, the rotating shaft device cannot be realized, and the use effect is not enough Ideal and other problems, to achieve the effect of prolonging the service life, solving the problems of hydraulic oil leakage and cam wear, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

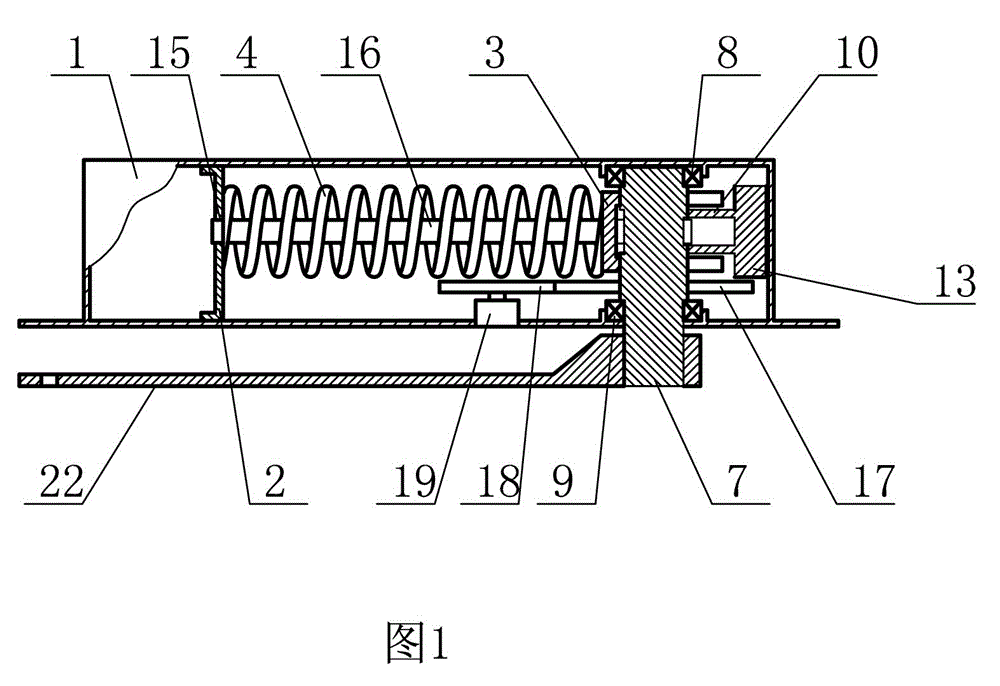

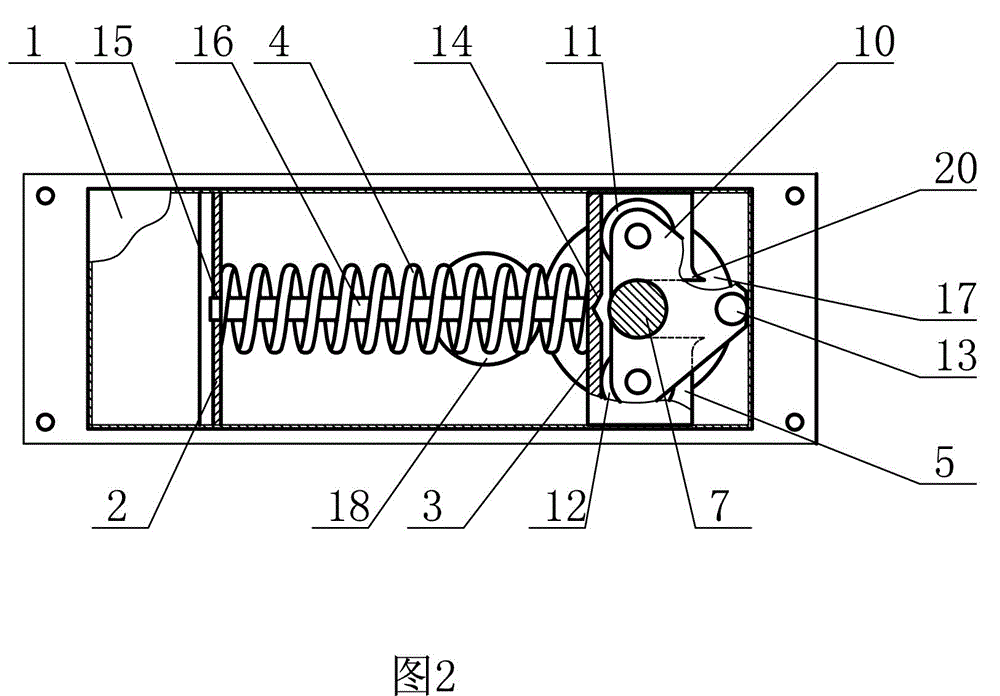

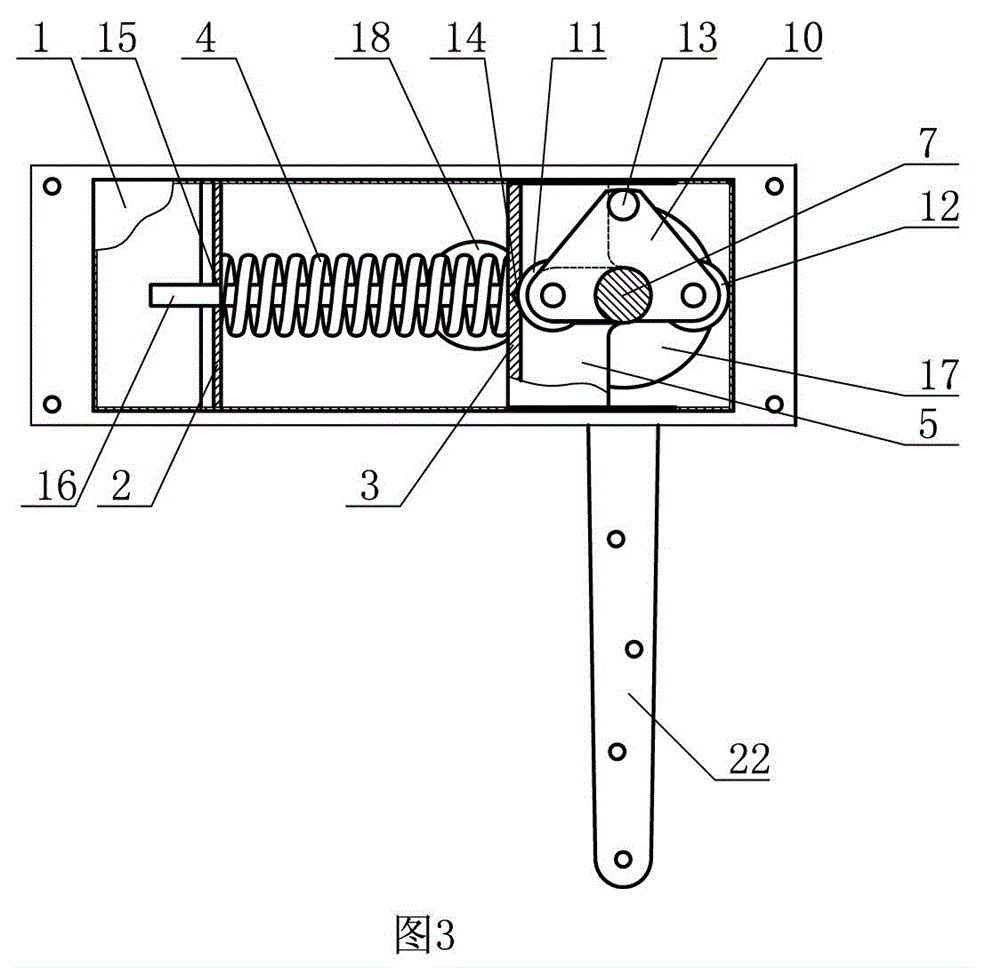

[0007] The multi-purpose automatic return positioning door shaft of the present invention includes a housing 1, a fixed seat 2 and a movable plate 3 are installed in the housing 1, a spring 4 is installed between the fixed seat 2 and the movable plate 3, and the movable plate 3 and the guide device connection, a positioning groove 14 is set on the movable plate 3, a side plate 5 is installed on the movable plate 3, a through groove 6 is set on the side plate 5, the rotating shaft 7 is connected with the housing 1 through the first bearing 8 and the second bearing 9, and the first bearing 8 is located at one end of the rotating shaft 7, the second bearing 9 is located at the middle of the rotating shaft 7, the other end of the rotating shaft 7 passes out of the casing 1, a rotating bracket 10 is installed on the rotating shaft 7, and a first roller 11, a second roller 12 and Boss 13. The present invention can be installed on the top of the door body as the upper door shaft of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com