Oil pipeline clamping fixture

A technology for clamping tooling and oil pipelines. It is used in packaging, transportation and packaging, and external frames. It can solve the problems of oil elbow shaking, pipeline damage, transportation difficulties, etc., and achieve impact mitigation, long service life, and opening and closing. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

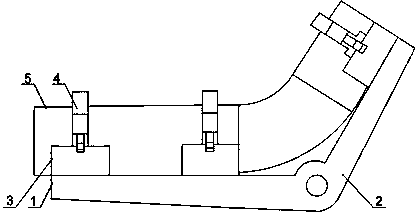

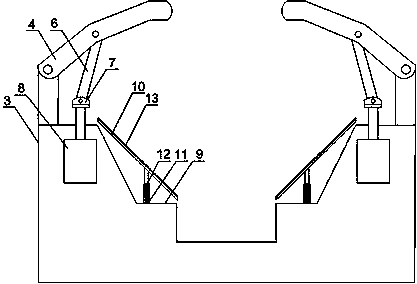

[0022] Such as Figure 1 to Figure 2 As shown, the oil pipeline clamping tooling of the present invention includes a base plate 1 and an adjusting plate 2, the end of the base plate 1 is hinged to the end of the adjusting plate 2, and clamping devices are installed on the base plate 1 and the adjusting plate 2. Block 3, the clamping block 3 is connected with the base plate 1 and the adjusting plate 2 through bolts, and also includes a pressure claw 4 and a connecting rod 6, the pressure claw 4 is connected with the upper end of the clamping block 6, and in the clamping block 3 A hydraulic cylinder 8 is installed, one end of the connecting rod 6 is hinged with the middle part of the pressure claw 4, the other end of the connecting rod 6 is hinged with the connecting block 7, and the telescopic end of the hydraulic cylinder 8 is connected with the bottom of the connecting block 7; The clamping block 3 is provided with a placement groove, and a boss 9 is arranged in the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com