Cake oven with split structure

An opening and closing structure, the technology of the scones machine, which is applied in the direction of the roaster/barbecue grid, kitchen utensils, household utensils, etc., can solve the problem of low processing efficiency, long baking time, unfavorable batch production and mass production and other problems, to achieve the effect of convenient use, easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

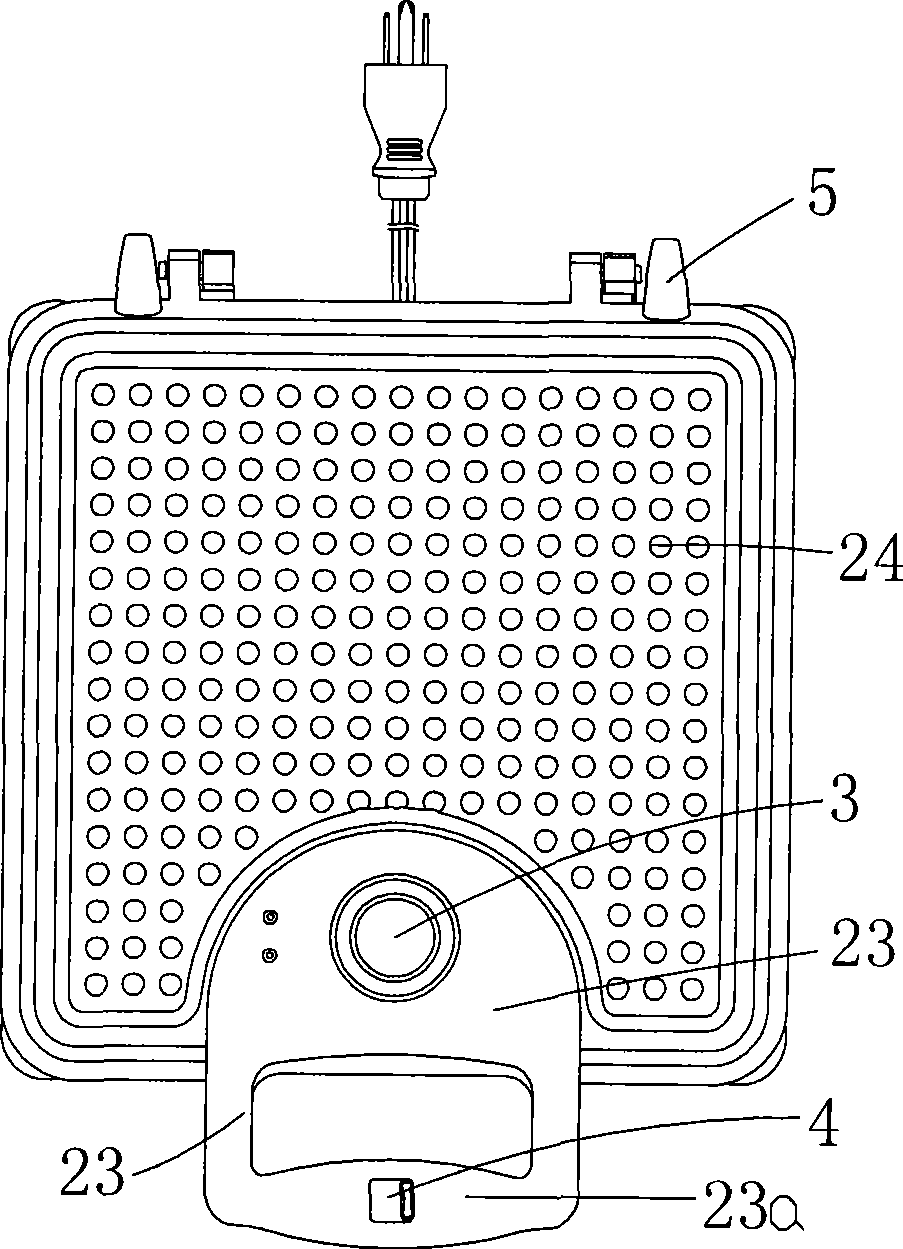

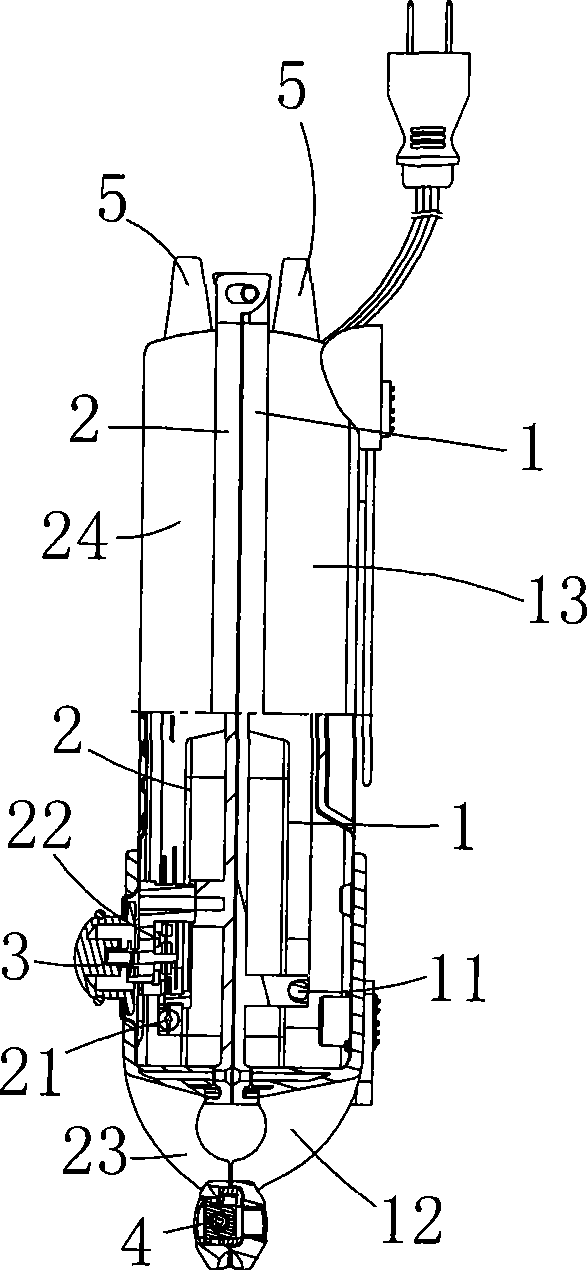

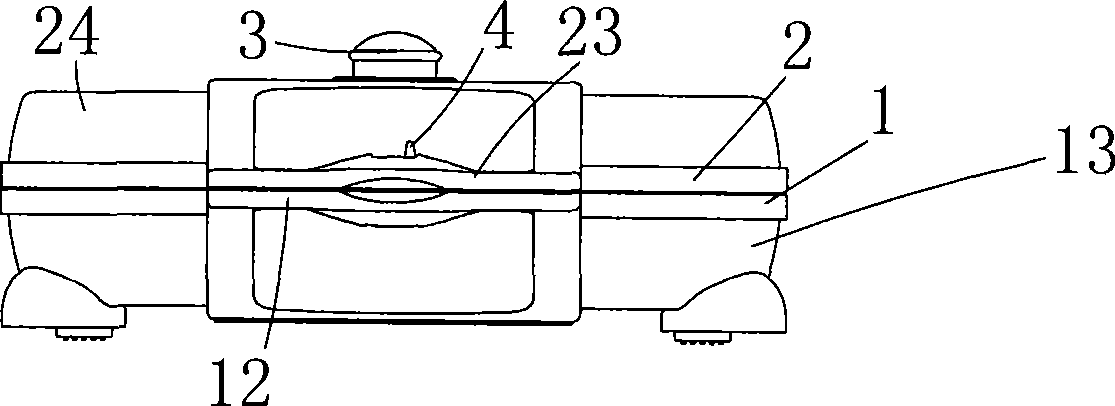

[0022] Such as Figure 1 to Figure 5 As shown, the symbol numbers are explained as follows: disk base body 1, first heat pipe 11, first handle body 12, first handshake edge 12a, first locking hole 12b, locking ring 12c, first cover body 13, first Install the handle surface 13a, the disc cover body 2, the second heat pipe 21, the temperature controller 22, the second handle body 23, the second handshake edge 23a, the second locking hole 23b, the second cover body 24, and the second installation handle Surface 24a, twist body 3, lock body 4, spring 41, side cover 42, handle cover 43, round foot body 5.

[0023] In the embodiment of the present invention, the biscuit machine with opening and closing structure includes a pan base body 1, a pan cover body 2 is hinged on the rear side of the pan base body 1, and a first heat pipe 11 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com