Horizontal automatic correction dynamic height variable adjusting device

An automatic correction and adjustment device technology, applied in the direction of motor vehicles, transportation and packaging, elastic suspension, etc., can solve the problems of insufficient adaptability and poor chassis passability, and achieve simple and convenient operation, easy control, improved passability and workability The effect of site adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

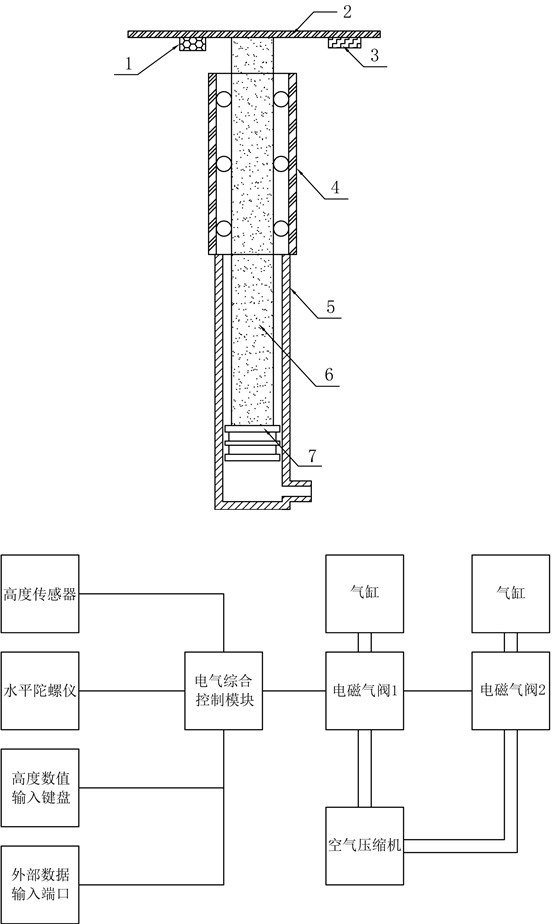

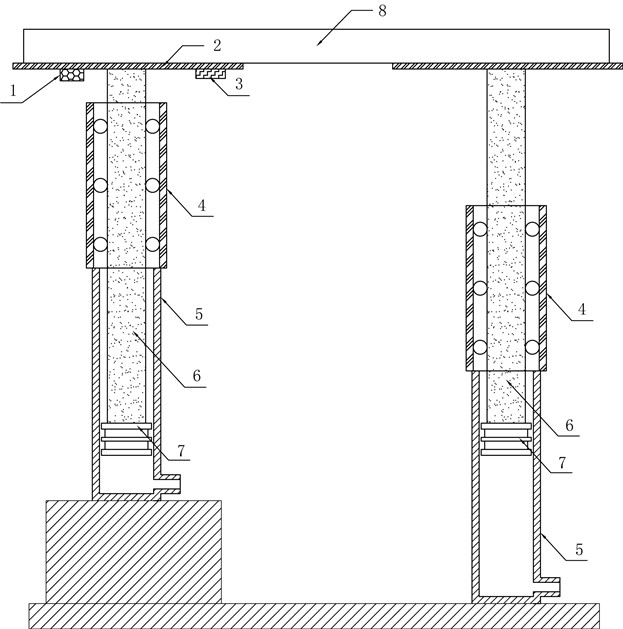

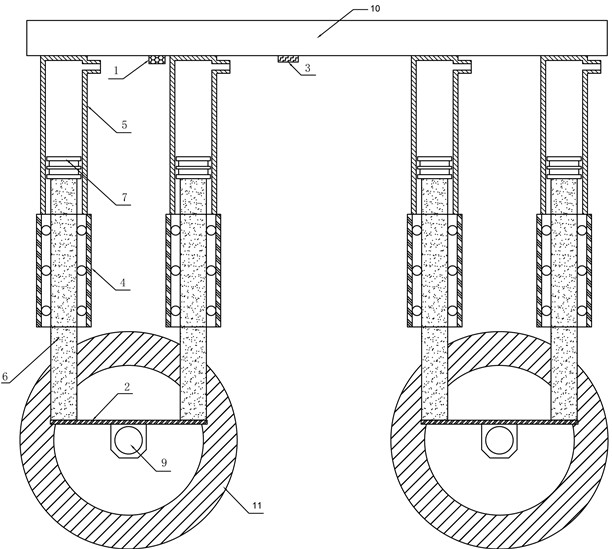

[0029] like figure 1 As shown in the figure, a horizontal automatic correction dynamic height variable adjustment device includes a cylinder 5, a piston 7, an electromagnetic valve, a linear bearing 4, an optical axis 6, a chassis platform 2, a horizontal gyroscope 3, a height sensor 1, and an electrical integrated control. Module, the piston 7 is fixed at one end of the optical axis 6 and can slide freely in the cylinder 5. The other end of the optical axis 6 is fixed on the chassis platform 2 through the linear bearing 4, and the upper part of the cylinder 5 is connected with the lower part of the linear bearing 4. , under the coordinated control of the horizontal gyroscope 3 and the height sensor 1, the electrical integrated control module controls the position of the piston 7 in the cylinder 5 through the solenoid valve, resulting in the effect of adjusting the height of the chassis platform 2.

[0030] The combined use of a plurality of the horizontal automatic correction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com