Patents

Literature

39results about How to "Easy misalignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

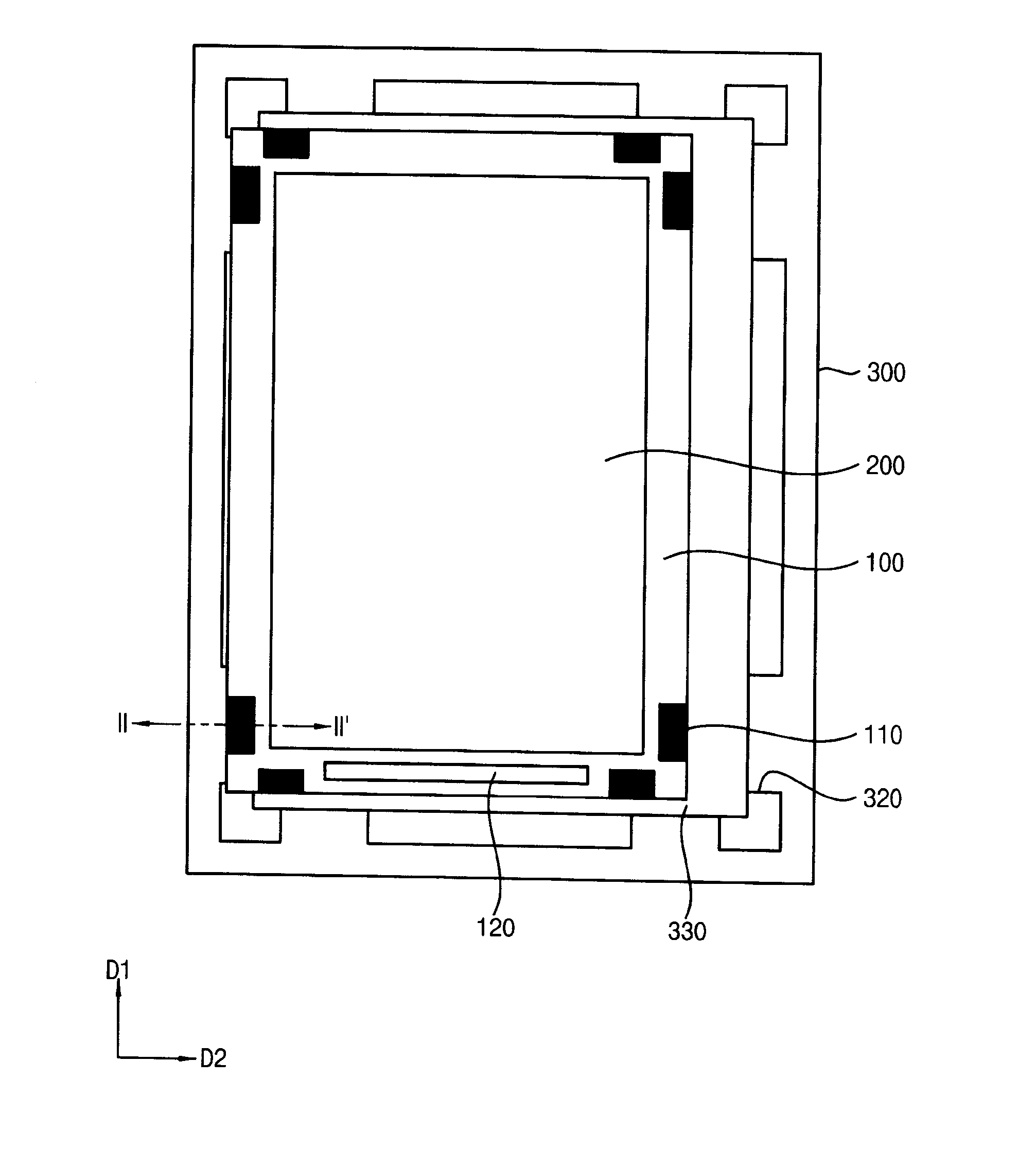

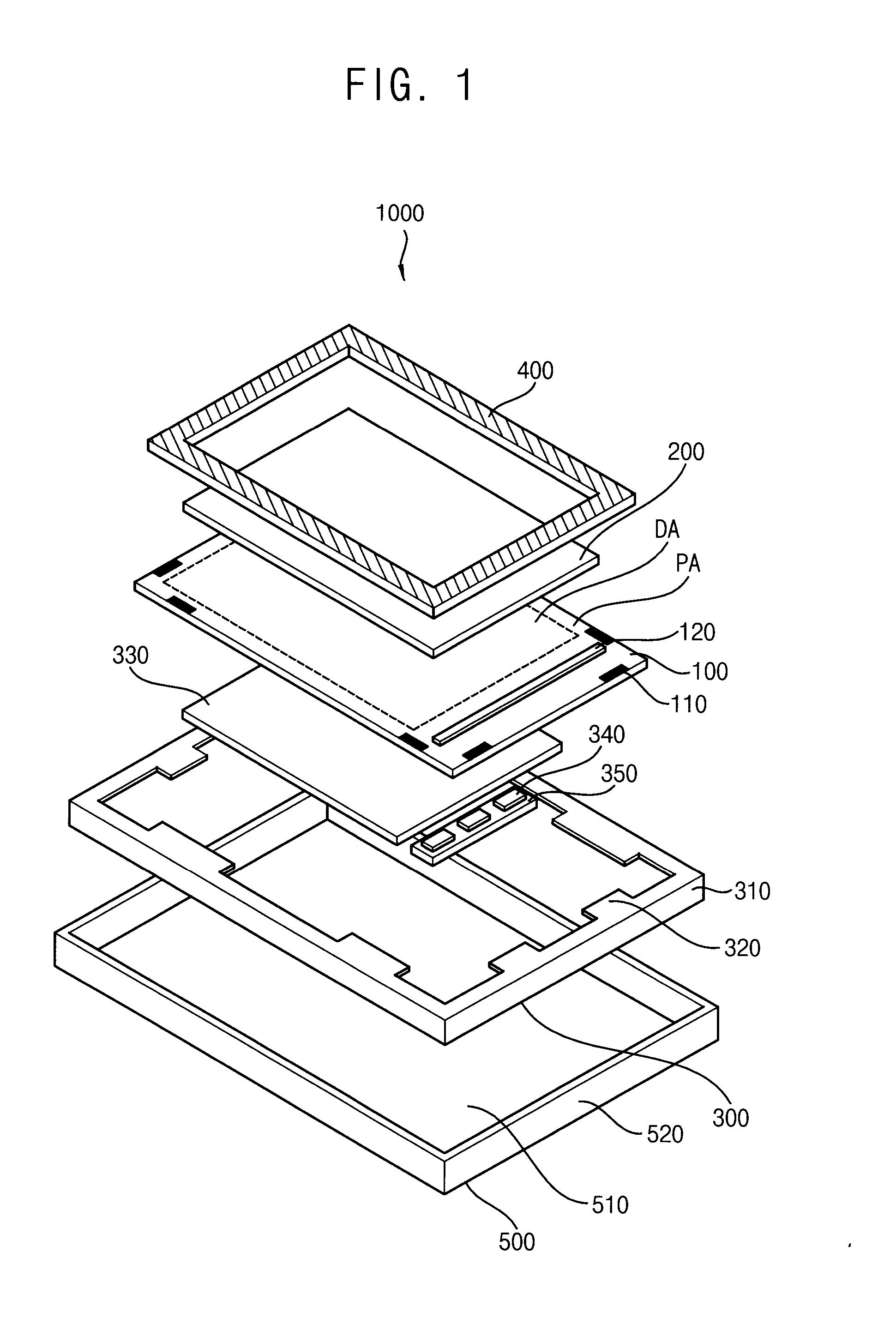

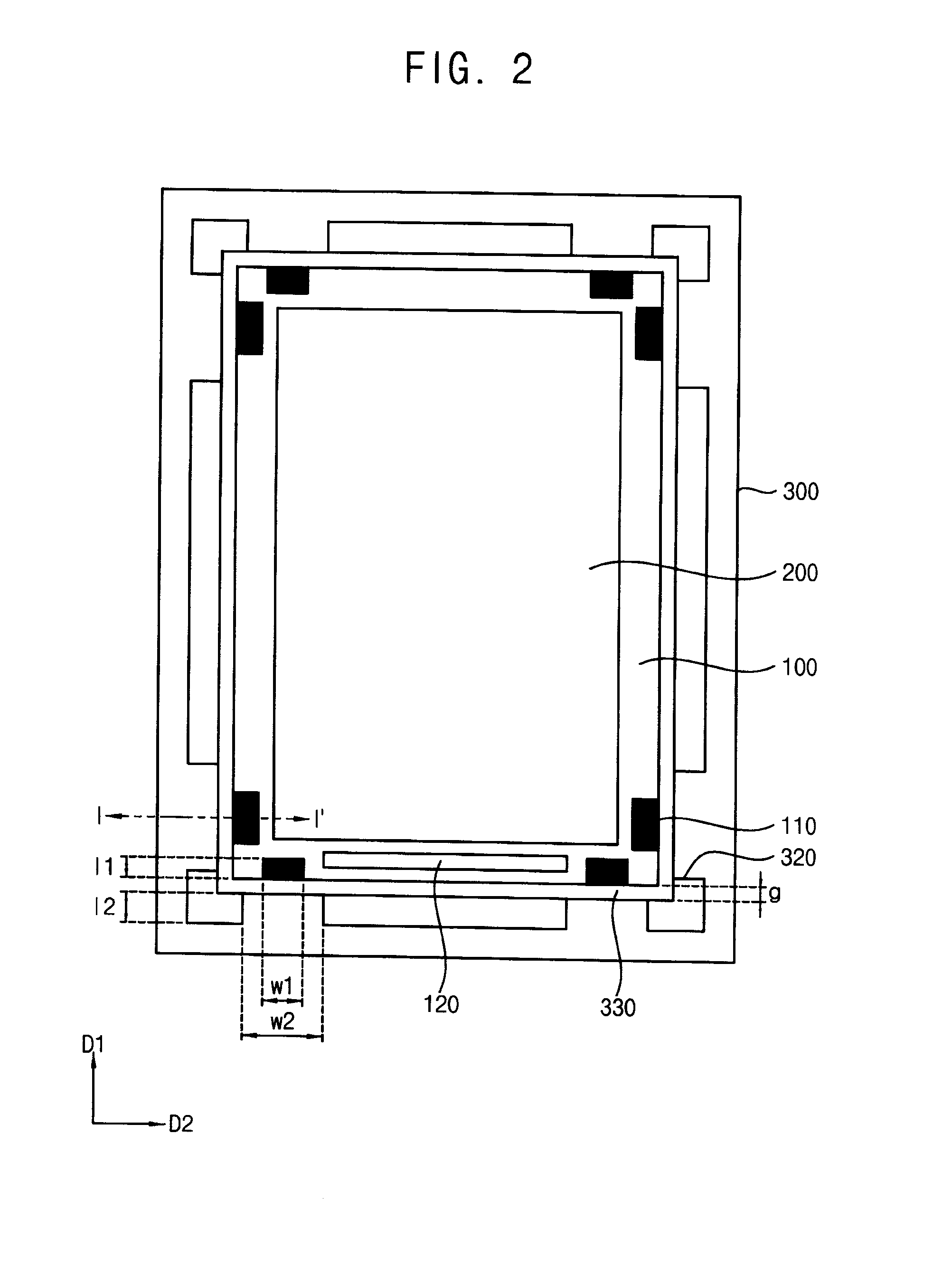

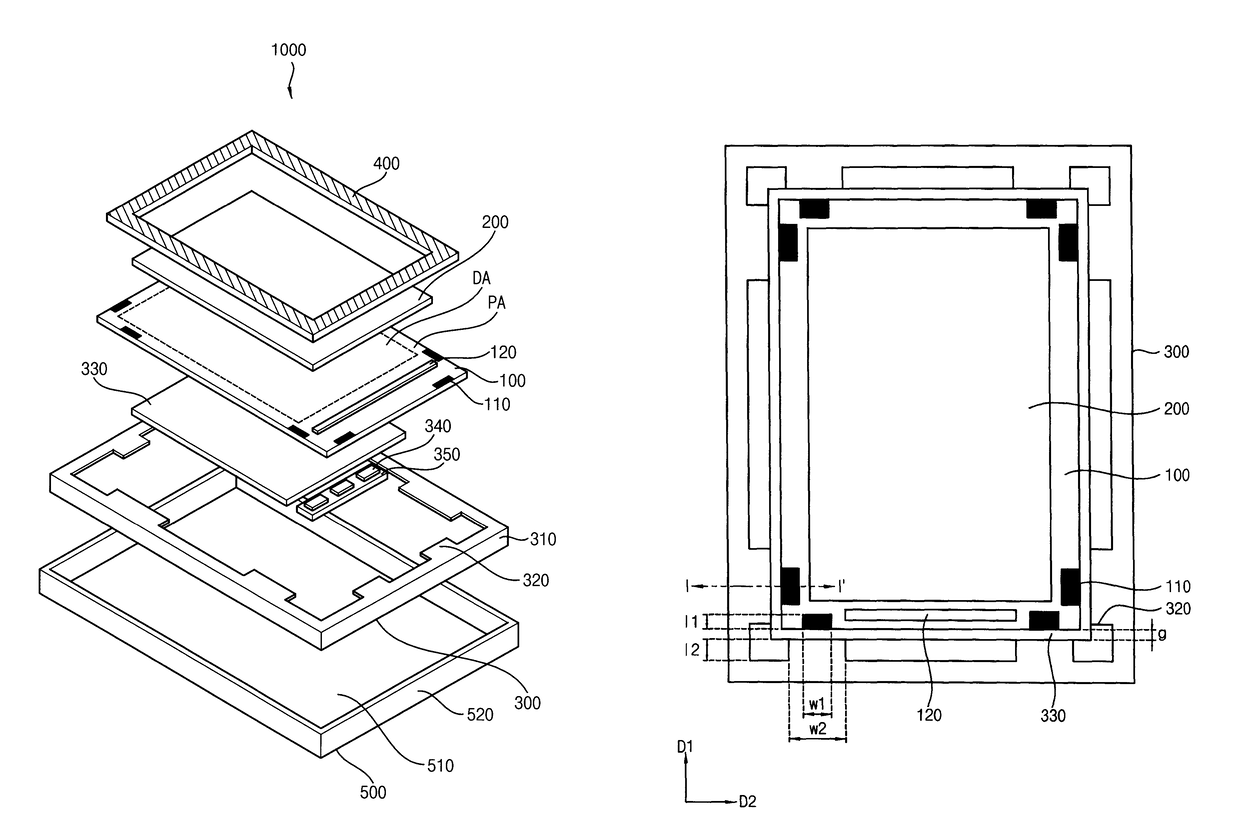

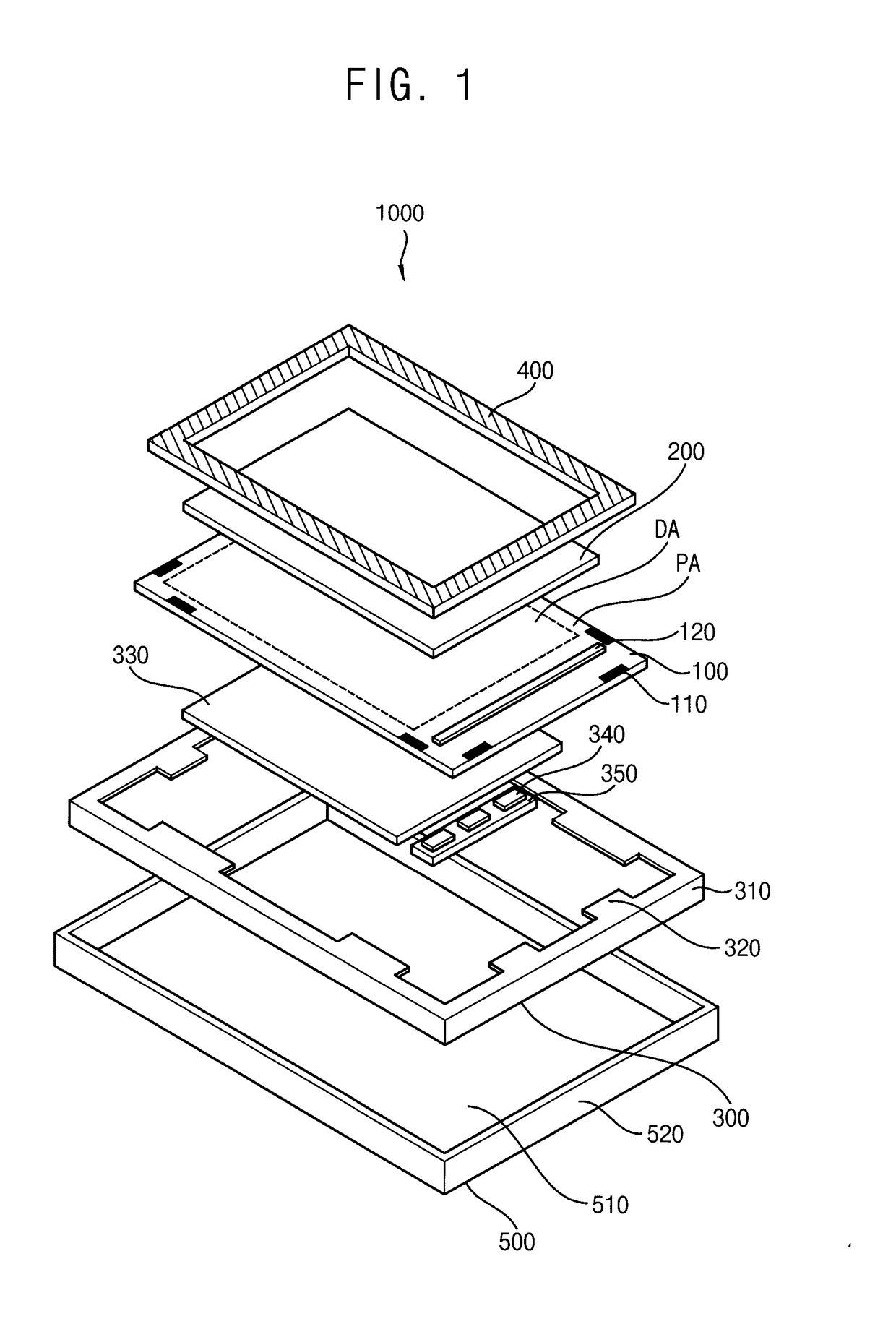

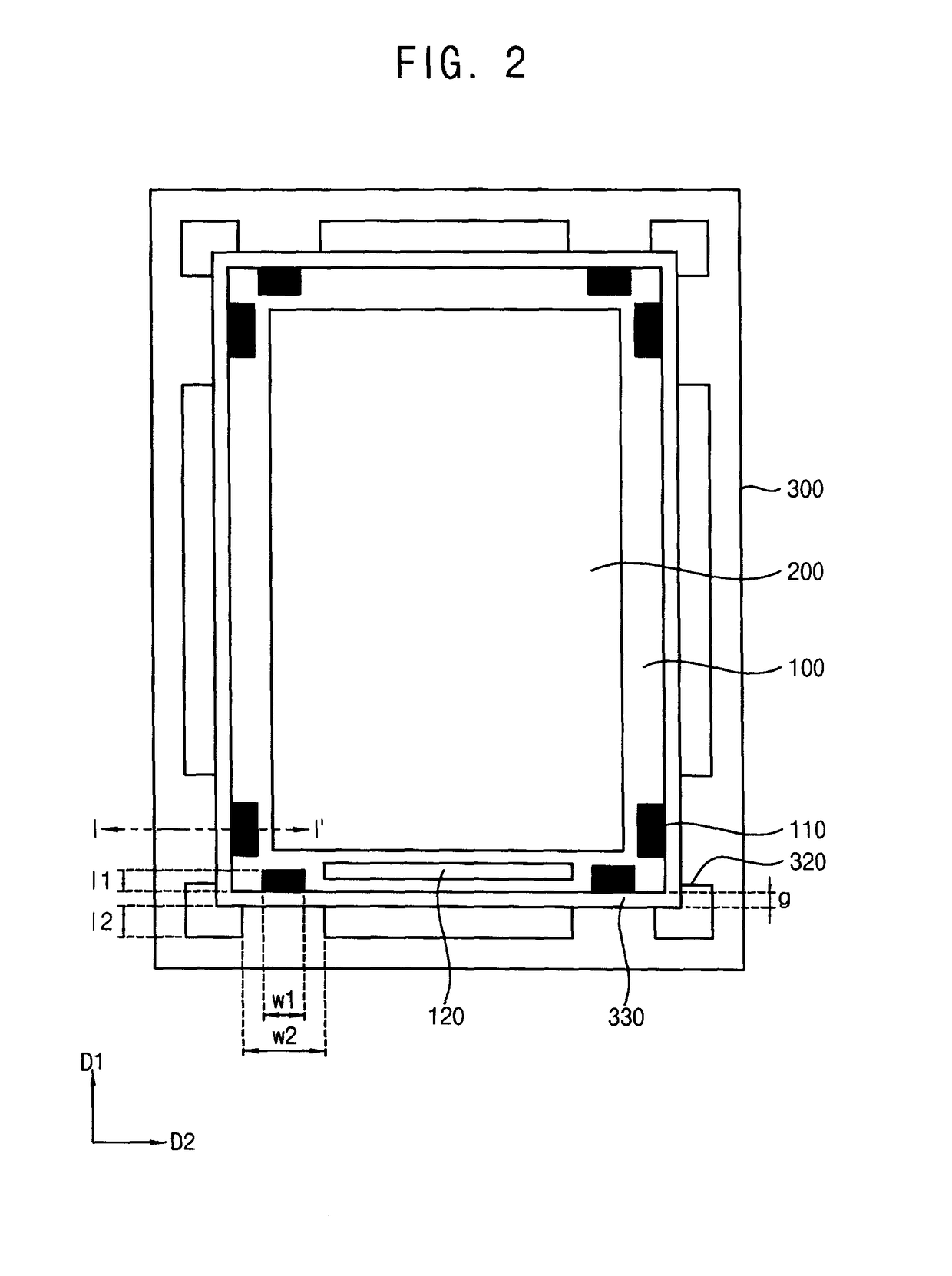

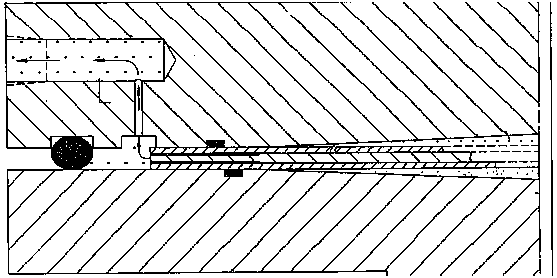

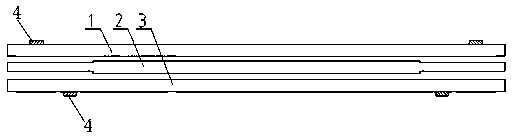

Display apparatus and method of manufacturing the same

InactiveUS20150131023A1Reduce misalignmentReduce display defectsVessels or leading-in conductors manufactureNon-linear opticsEngineering

A display apparatus includes a display panel and a mold frame. The display panel includes a display area, a peripheral area surrounding the display area, an alignment mark on the peripheral area, and a cover element overlapping the alignment mark to cover the alignment mark. The mold frame has a frame shape configured to receive the display panel. The mold frame includes a panel guide protrusion protruding from an inner surface of the mold frame, and the panel guide protrusion is adjacent to the alignment mark.

Owner:SAMSUNG DISPLAY CO LTD

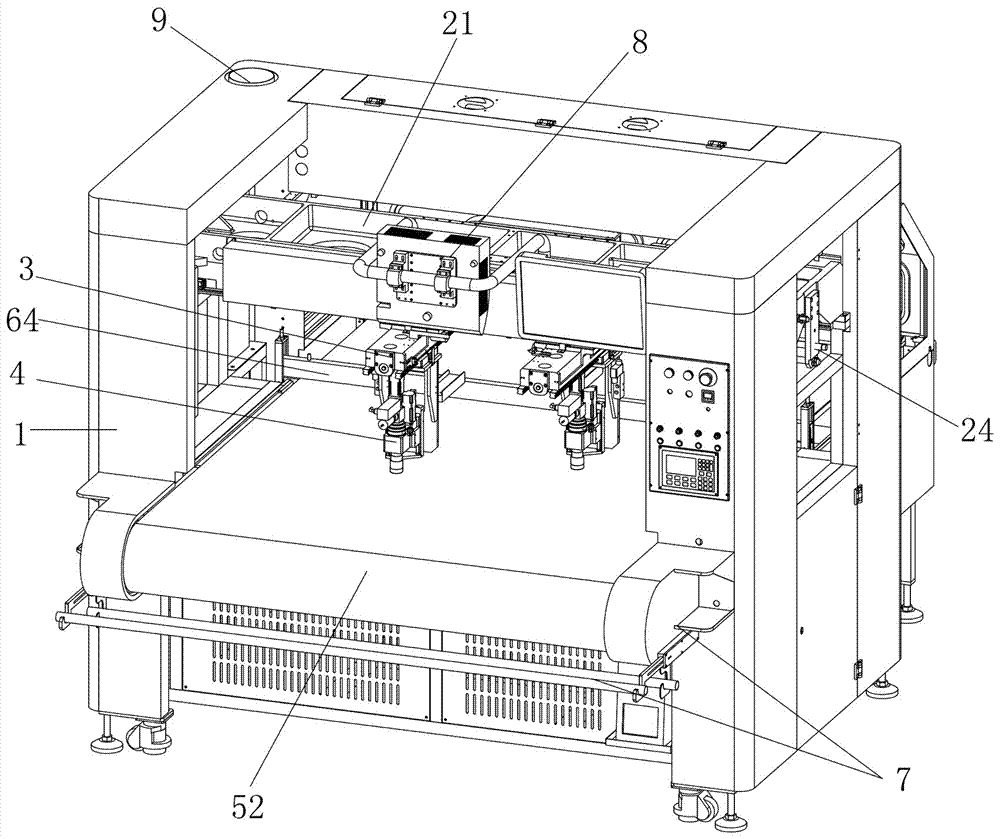

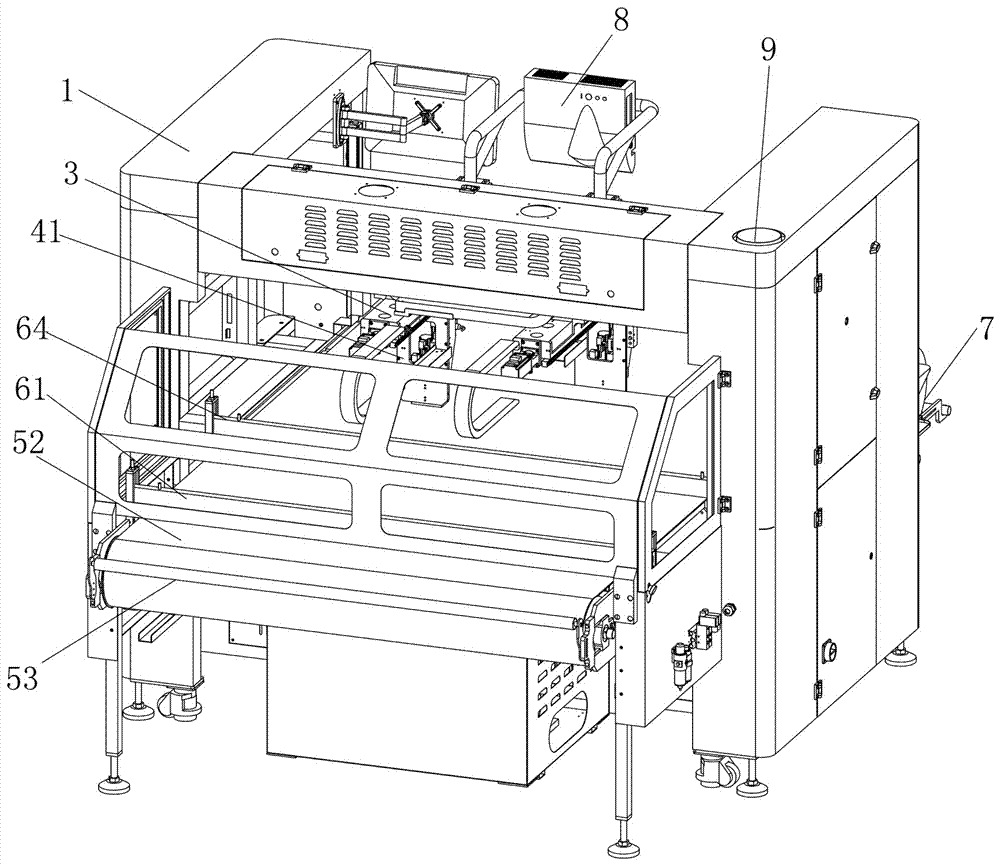

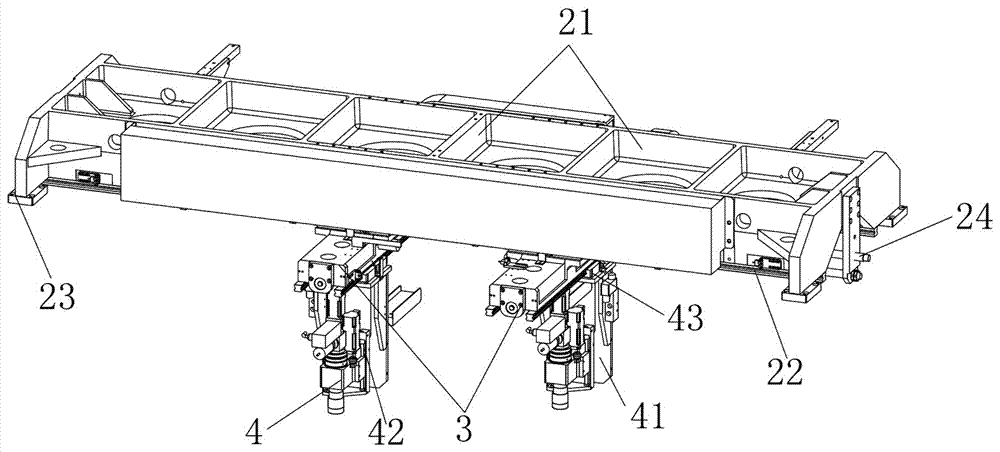

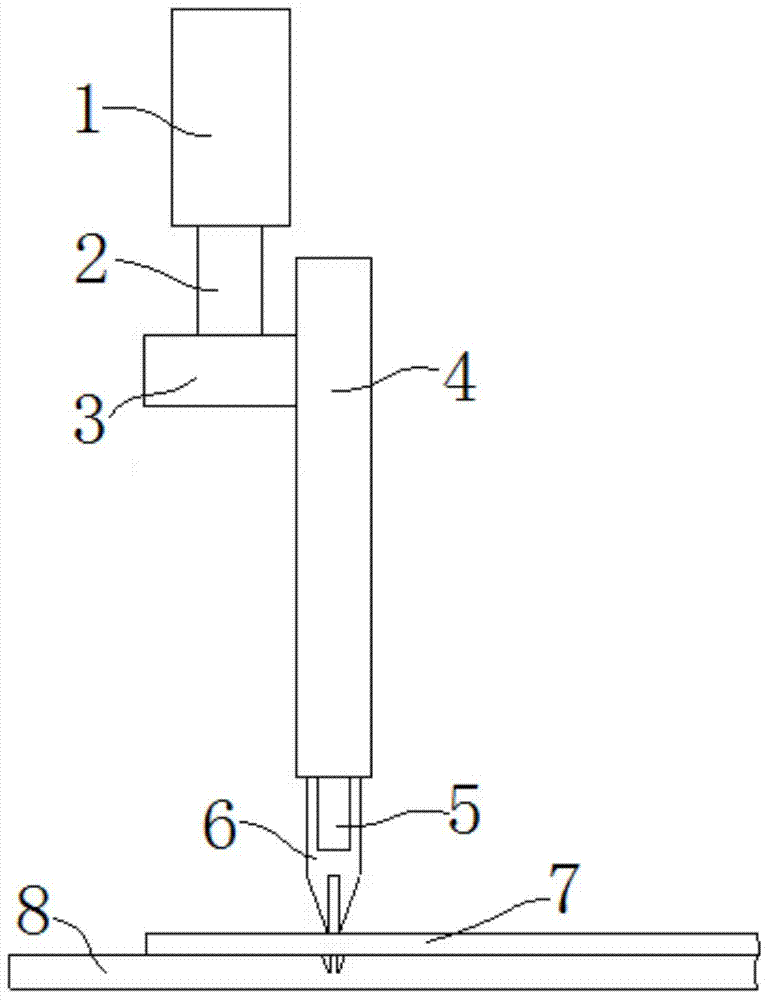

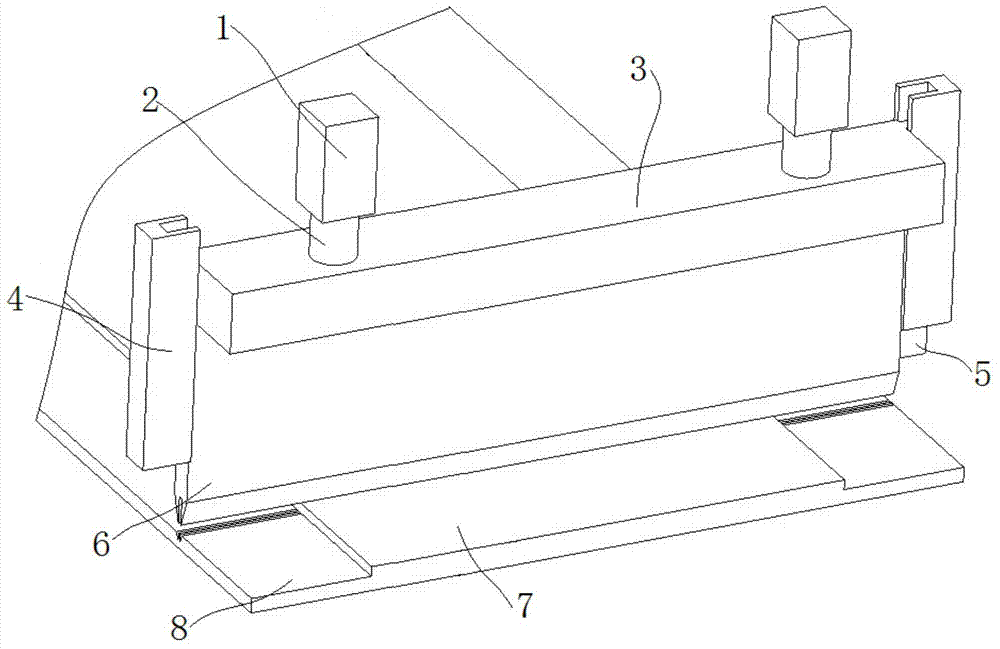

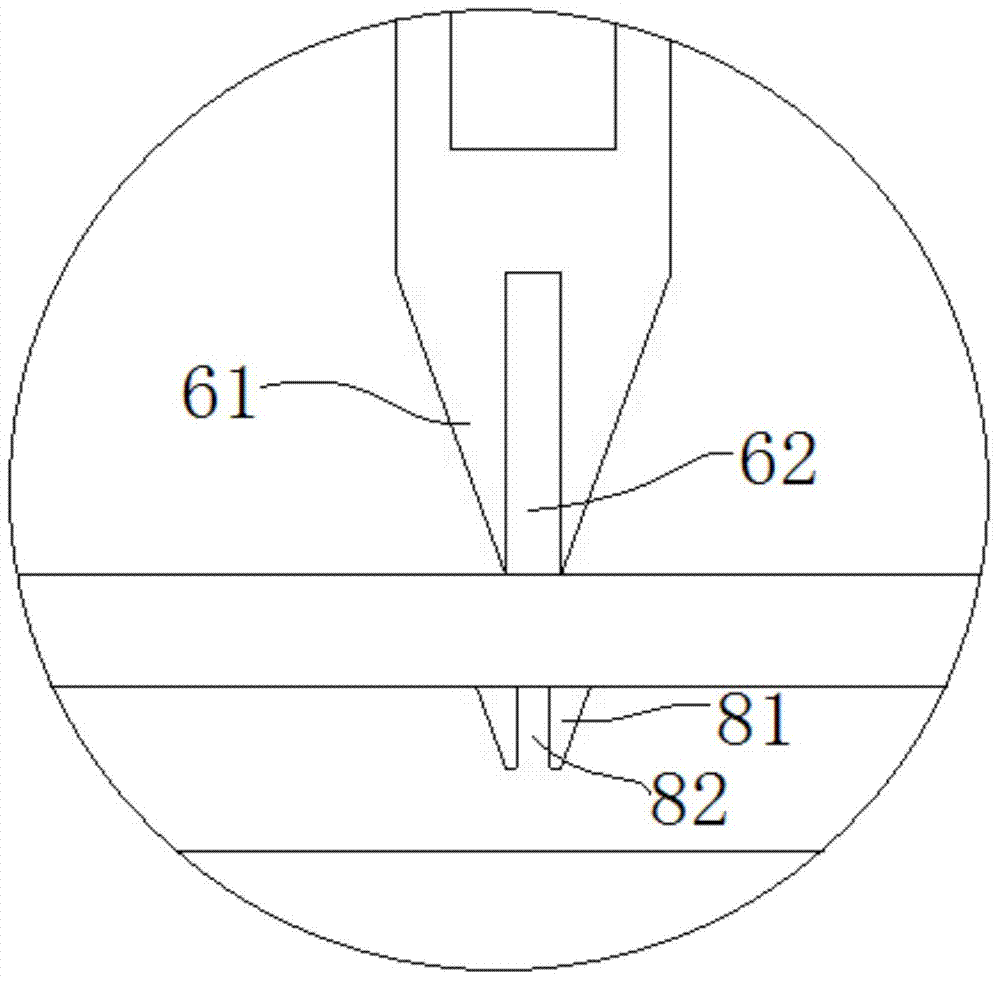

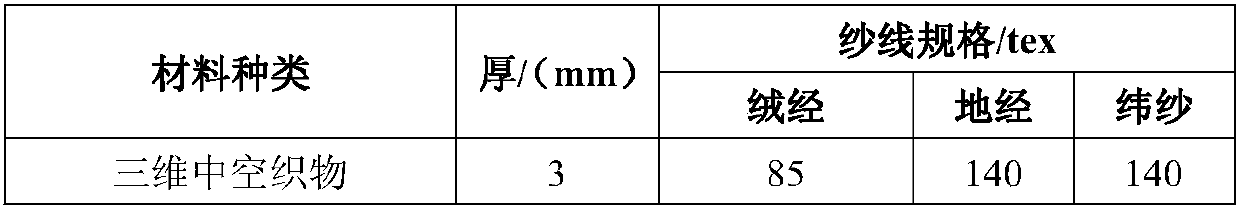

Cutting machine

InactiveCN106930092ANo misalignmentEnsure consistencySevering textilesThree-dimensional spaceEngineering

The invention discloses a cutting machine. The cutting machine comprises a frame and a feeding device which is arranged on the frame, wherein a feed inlet, a cutting station and a product collecting station are successively arranged on the frame along the feeding direction of the feeding device; a portal frame is arranged above the cutting station of the frame, the portal frame hoists at least one tool apron for mounting a tool, a mobile device which drives the tool apron to move in a three-dimensional space is arranged between the portal frame and the tool apron, and a traction material pressing device and a fixed pressing device are successively arranged along the feeding direction between the feed inlet and the cutting station. Cloth and a conveyor belt are clamped together and moved through the traction pressing device, so that the cloth in the transfer process is not staggered, and meanwhile, the cloth is tightly pressed to the conveyor belt through the fixed pressing device, so that the cloth cutting consistency and precision are guaranteed, and the problem that the cloth which is cut is easy to be staggered is solved.

Owner:GBOS LASER INC

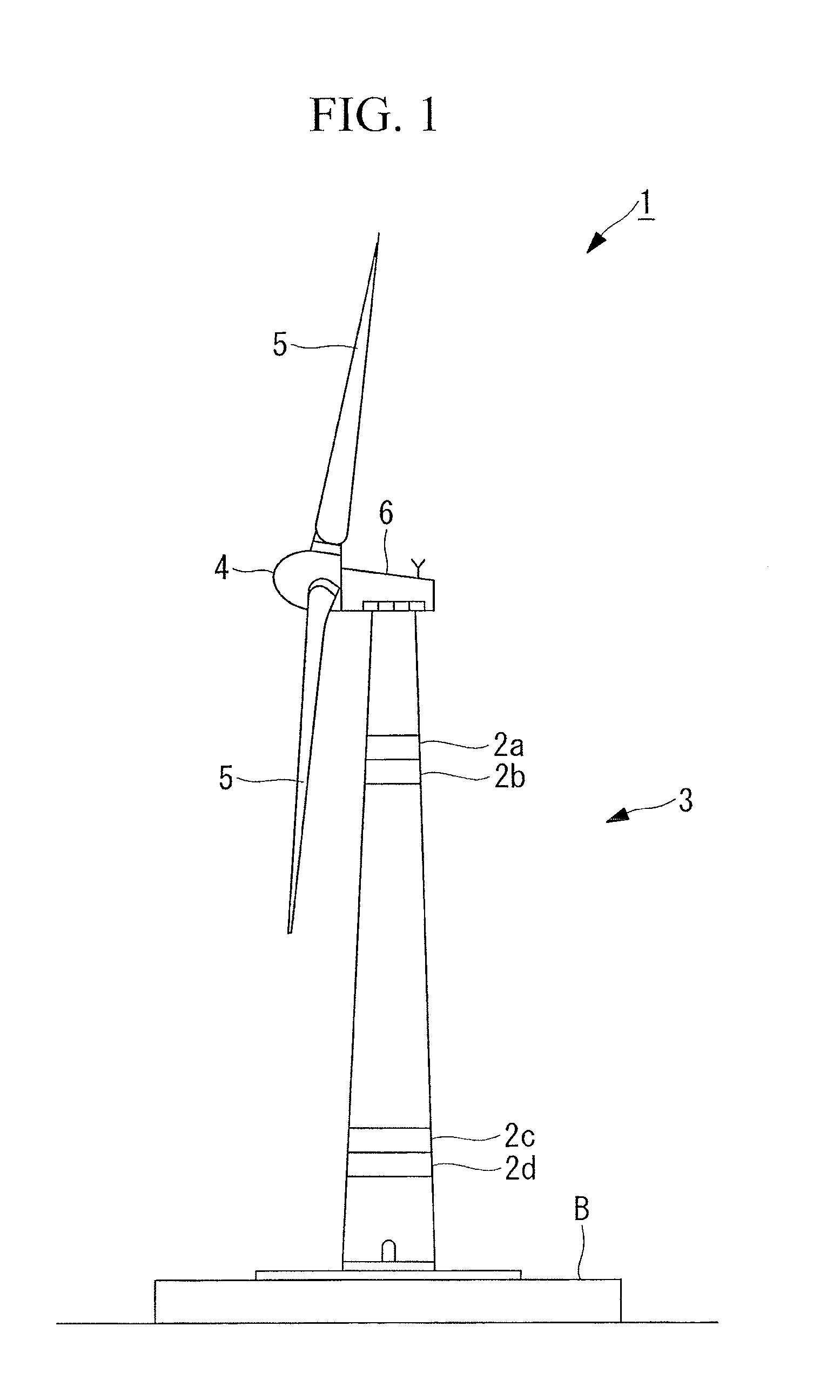

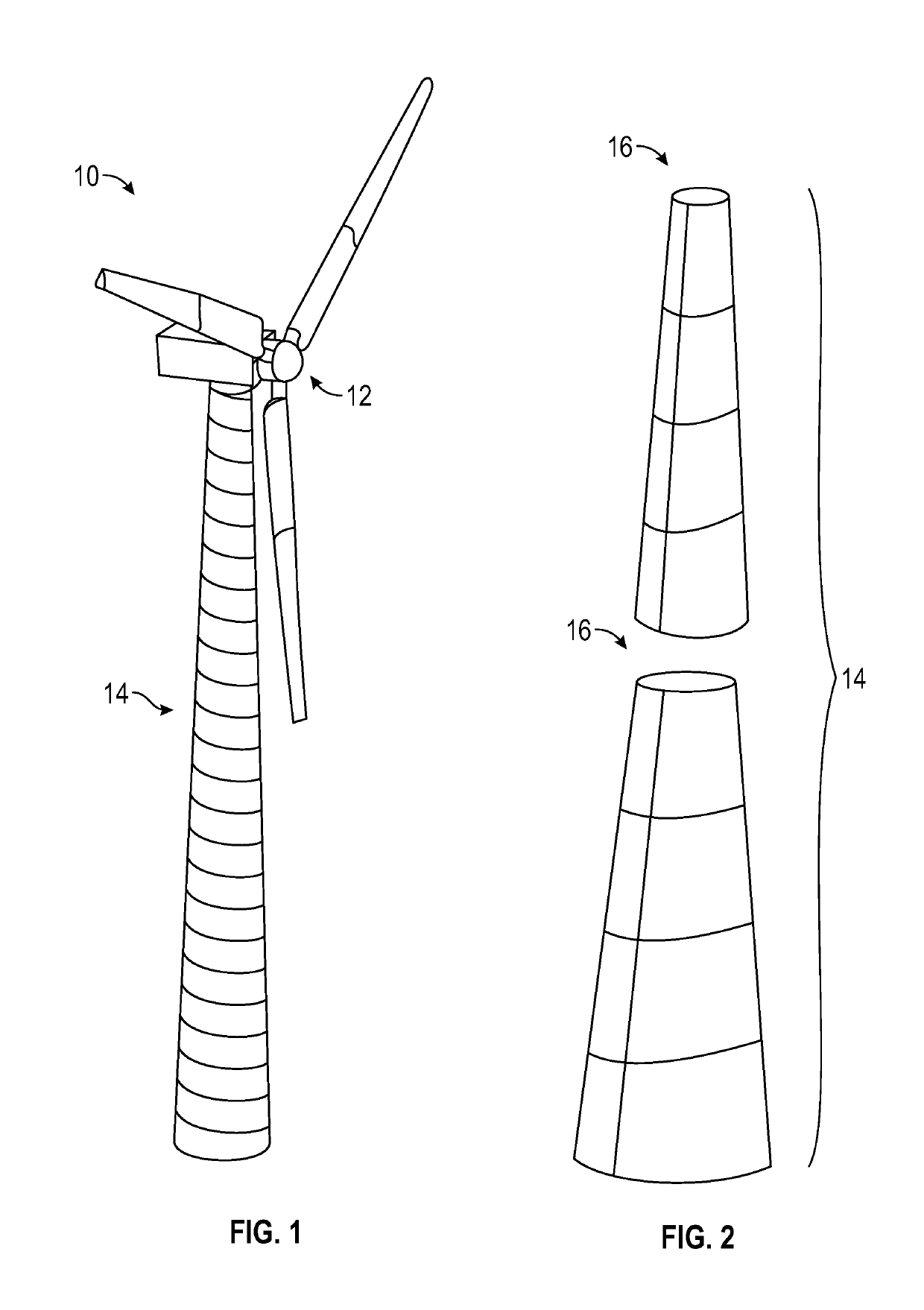

Tower and wind turbine generator having the same

InactiveUS20130205686A1High manufacturing accuracyLower manufacturing requirementsTowersBuilding reinforcementsMarine engineeringTower

Provided are a tower that has a sufficient yield strength and enables connection between tower sections without requiring a high manufacturing accuracy of the tower sections, and a wind turbine generator having the tower. The tower includes a plurality of tower sections formed by dividing the tower along planes that are parallel to a horizontal plane, and is constituted by connecting end surfaces of the tower sections to each other. The tower further includes a tensile member that has one end supported by a first supporting part at a first tower section among the tower sections, has another end supported by a second supporting part at a second tower section among the tower sections or at a tower base on which the tower is vertically installed, and is stretched along an inner wall of the tower sections so as to have a predetermined tensile force.

Owner:MITSUBISHI HEAVY IND LTD

Carton mark pressing device with cartons pasted accurately

InactiveCN103879028AEasy misalignmentWide range of applicationsPaper-makingBox making operationsDislocationEngineering

The invention discloses a carton mark pressing device with cartons pasted accurately and belongs to the field of carton mark pressing devices. The carton mark pressing device with cartons pasted accurately comprises an air cylinder, a piston rod, a fixed connecting piece and an upper mark pressing plate. The air cylinder is connected with the fixed connecting piece fixedly installed on the side face of the upper mark pressing plate through the piston rod. Two pairs of sharp edges are symmetrically arranged at the bottom of the upper mark pressing plate, and a cavity with the cross section being rectangular is defined by the two pairs of sharp edges. A lower mark pressing plate is arranged below the upper mark pressing plate. Grooves are formed in the positions, corresponding to the two pairs of sharp edges, on the lower mark pressing plate, the grooves are matched with the sharp edges, a convex rib with the cross section being rectangular is formed between the two grooves, and the convex rib is matched with the cavity. The carton mark pressing device with cartons pasted accurately not only can solve the problem that cartons are prone to dislocation in the carton pasting process and guarantee that the cartons are formed accurately but also can avoid that different sinking degrees need to be adjusted because of different kinds of corrugated paper, and is wide in application range.

Owner:江苏东方印务有限公司

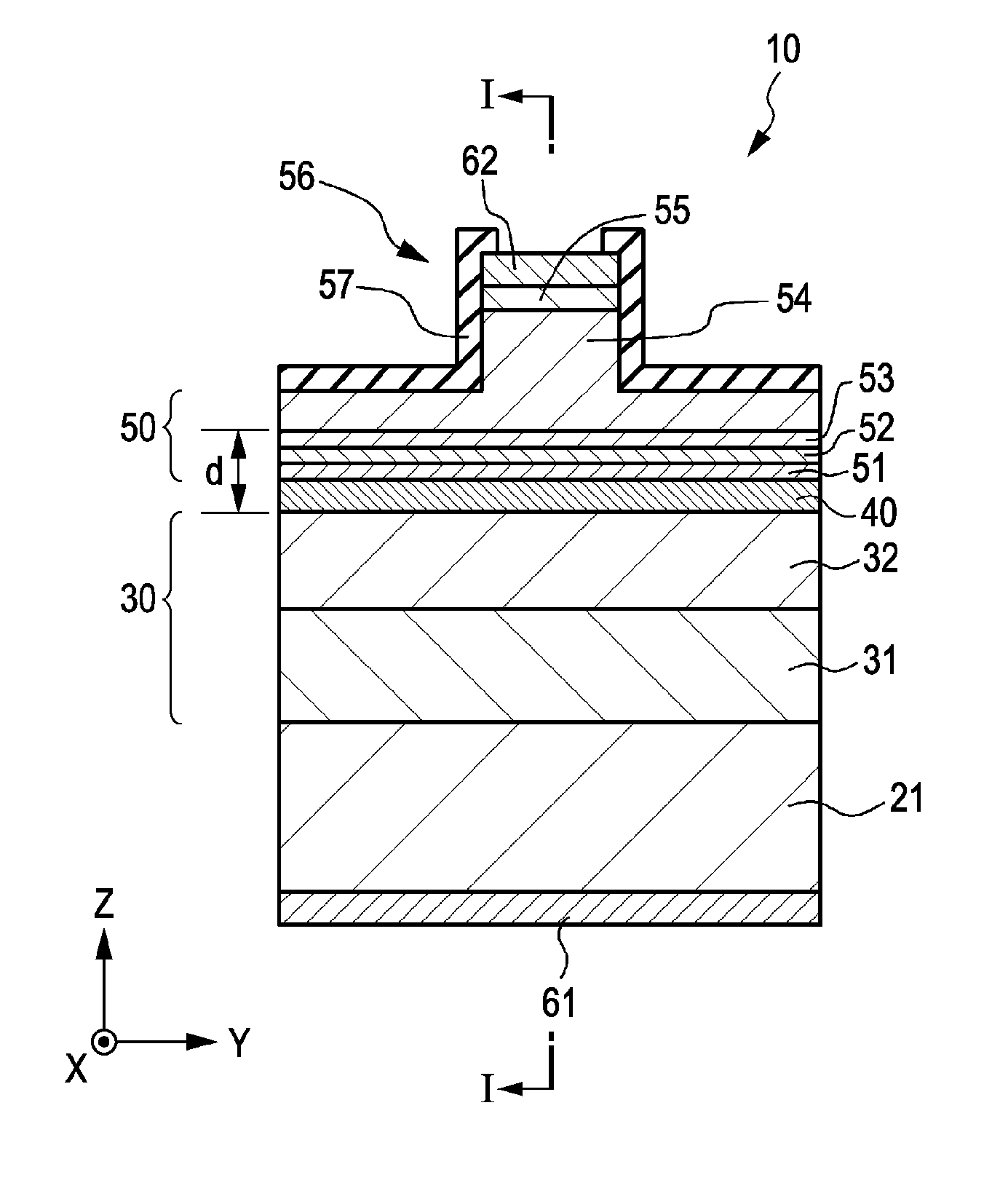

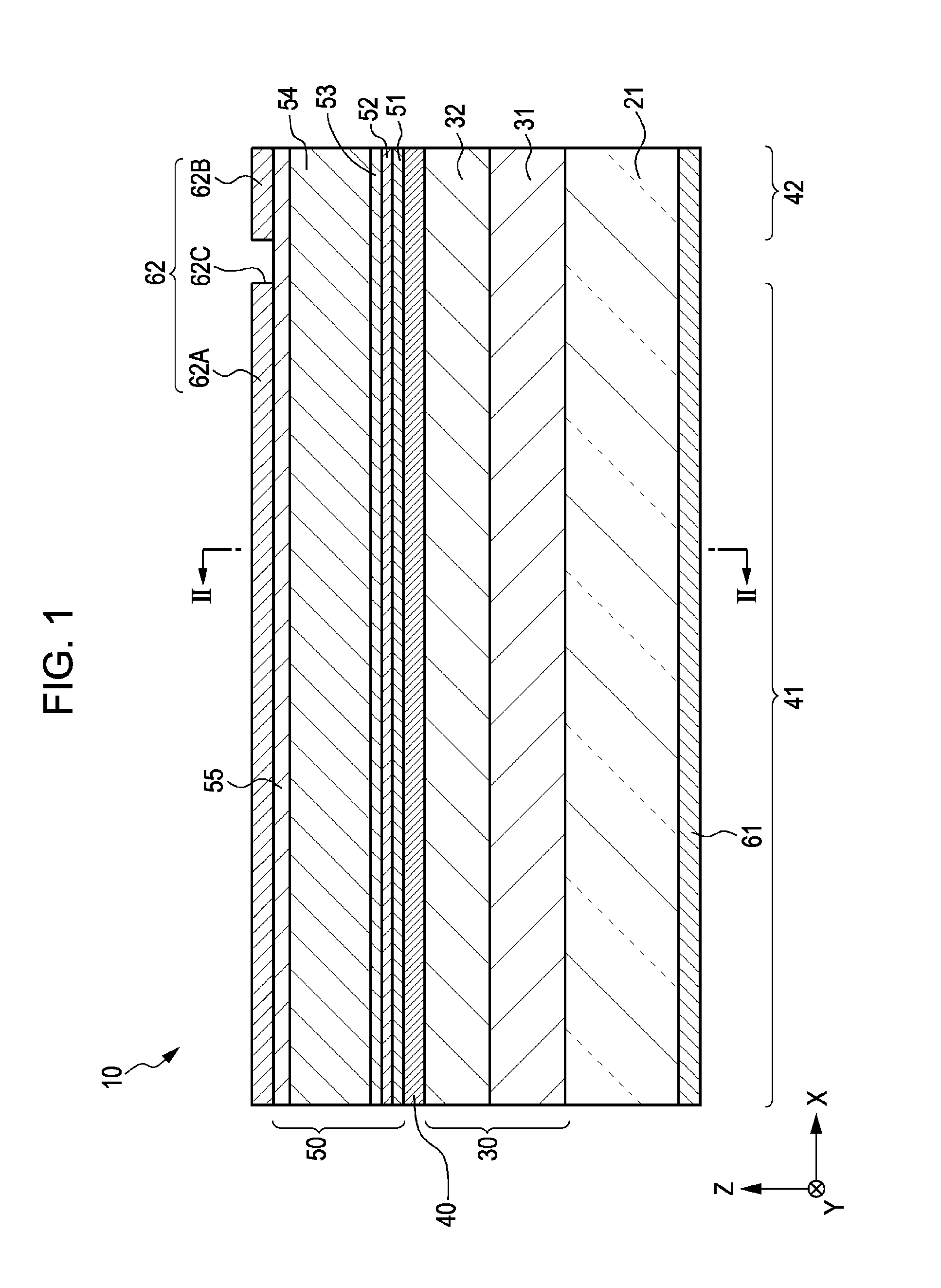

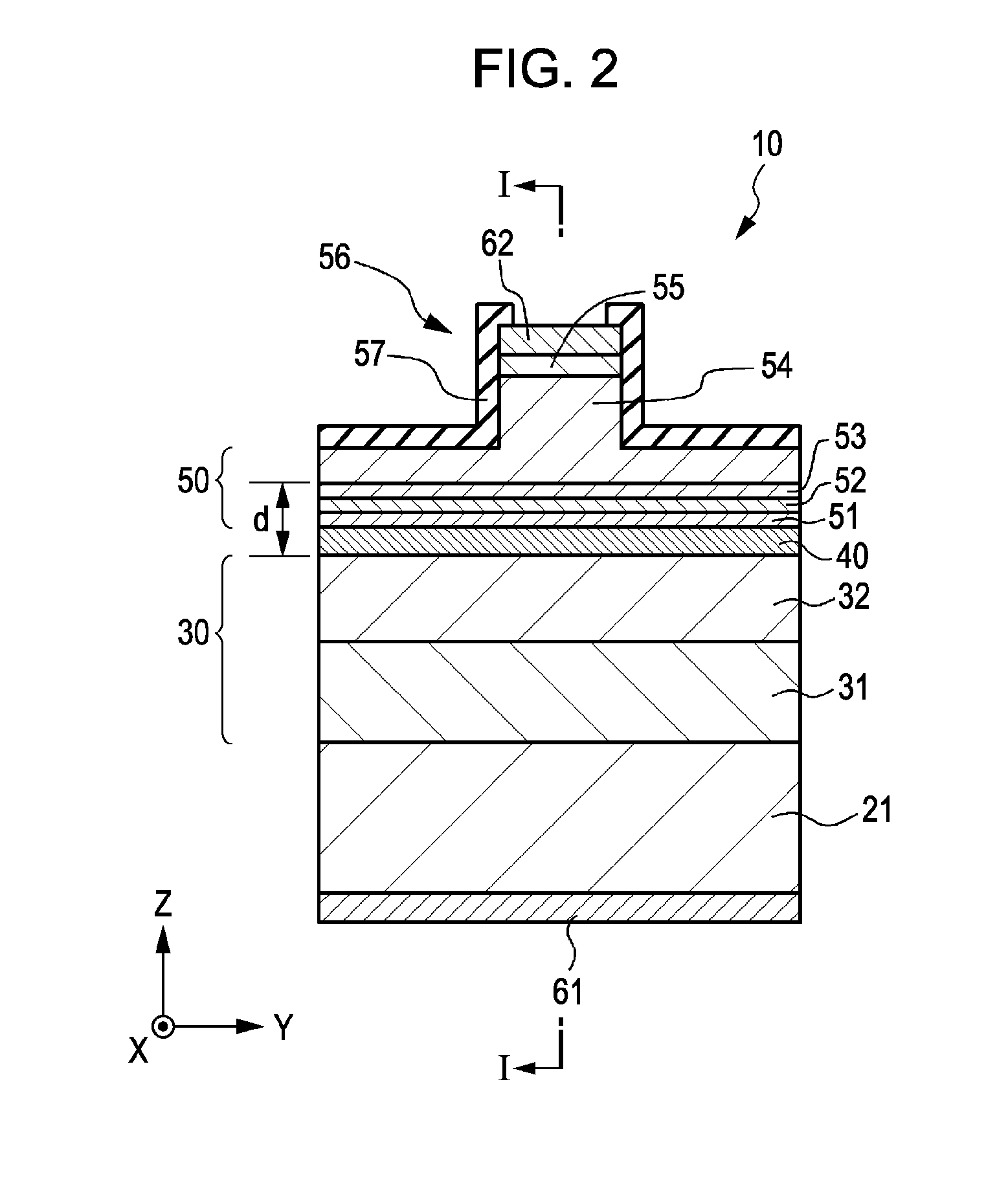

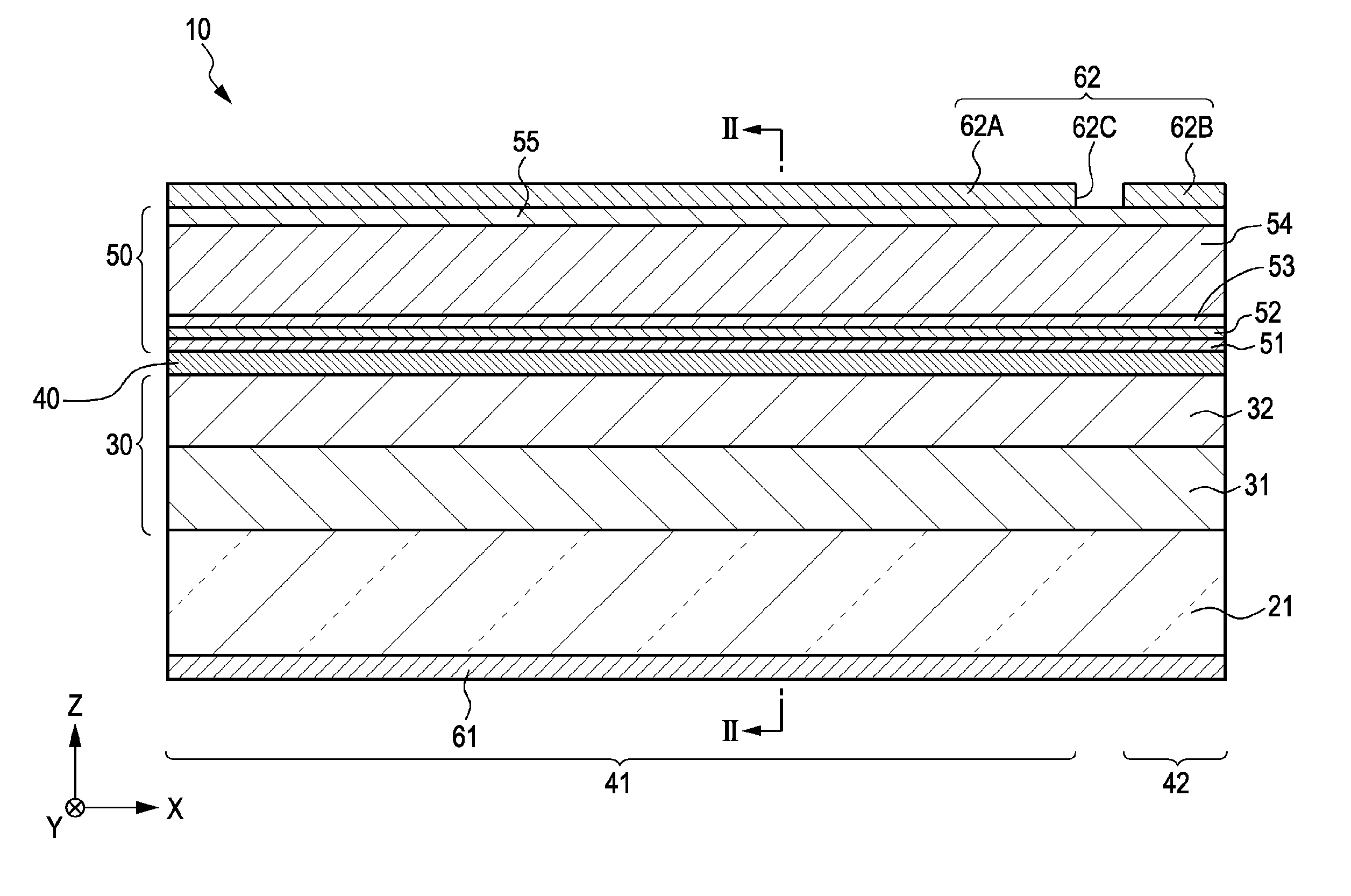

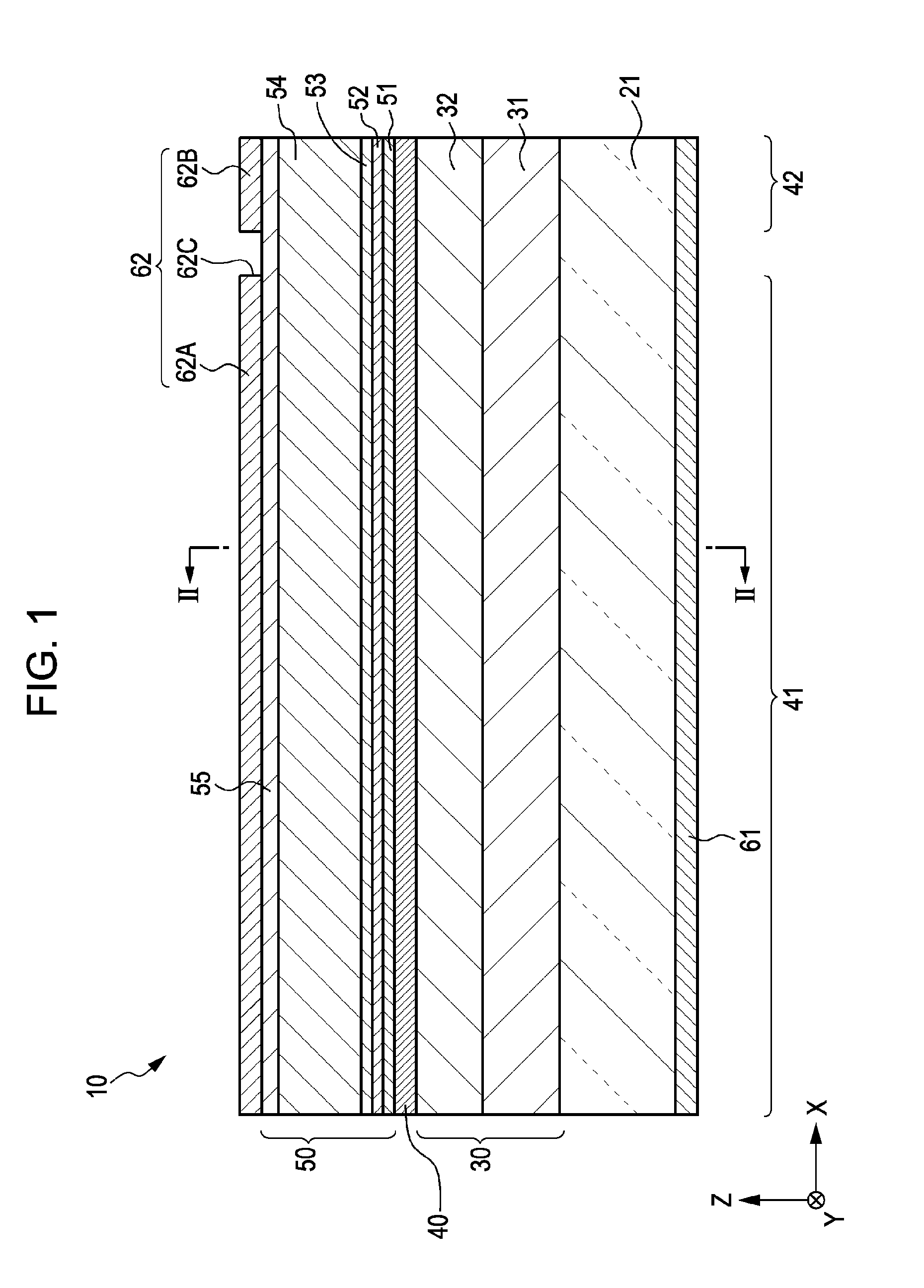

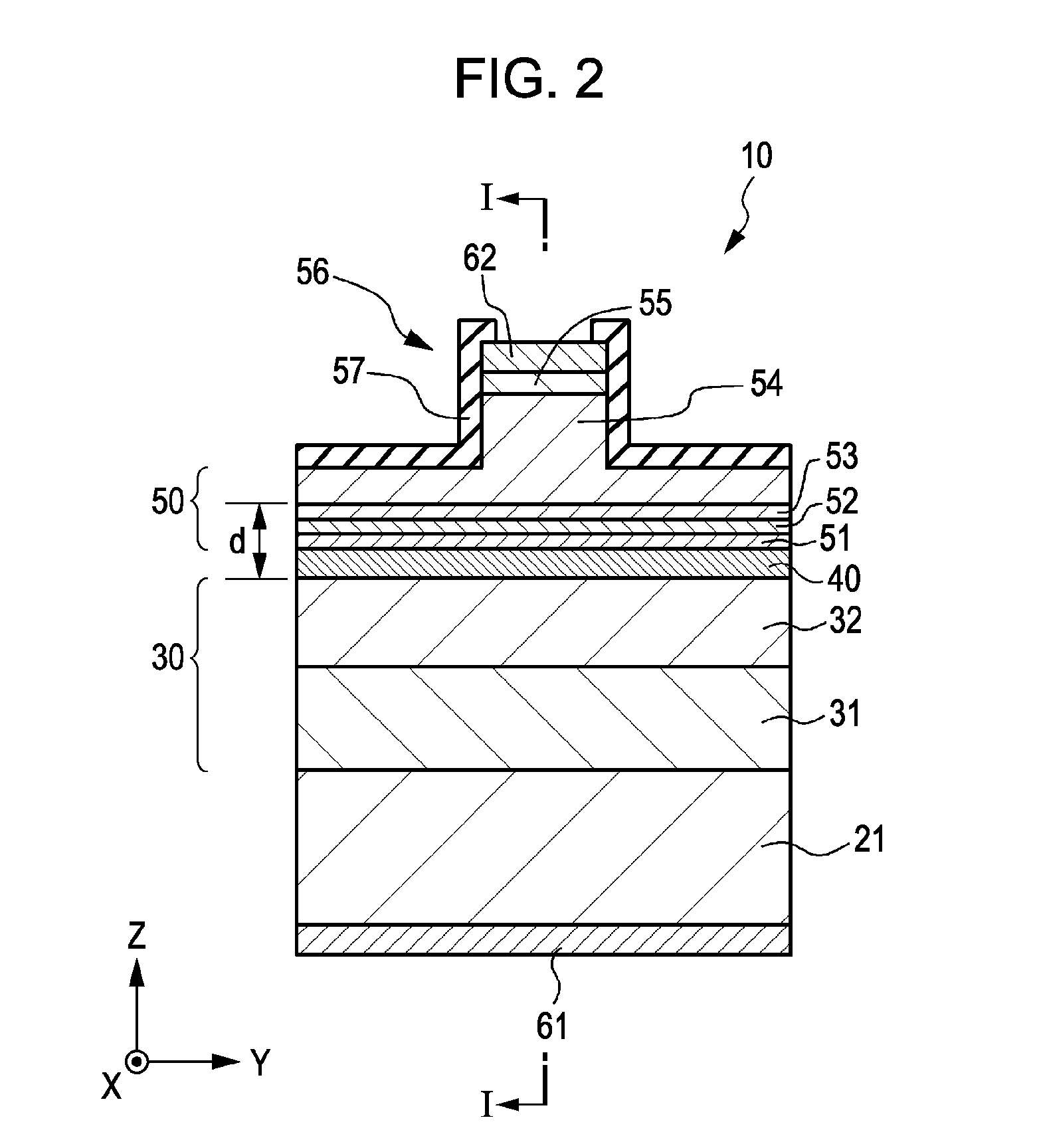

Bi-section semiconductor laser device, method for manufacturing the same, and method for driving the same

ActiveUS20100246622A1Characteristic be suppressedDegradation of optical be suppressedOptical wave guidanceLaser detailsResistEtching

A method for manufacturing a bi-section semiconductor laser device includes the steps of (A) forming a stacked structure obtained by stacking, on a substrate in sequence, a first compound semiconductor layer of a first conductivity type, a compound semiconductor layer that constitutes a light-emitting region and a saturable absorption region, and a second compound semiconductor layer of a second conductivity type; (B) forming a belt-shaped second electrode on the second compound semiconductor layer; (C) forming a ridge structure by etching at least part of the second compound semiconductor layer using the second electrode as an etching mask; and (D) forming a resist layer for forming a separating groove in the second electrode and then forming the separating groove in the second electrode by wet etching so that the separating groove separates the second electrode into a first portion and a second portion.

Owner:SONY CORP +1

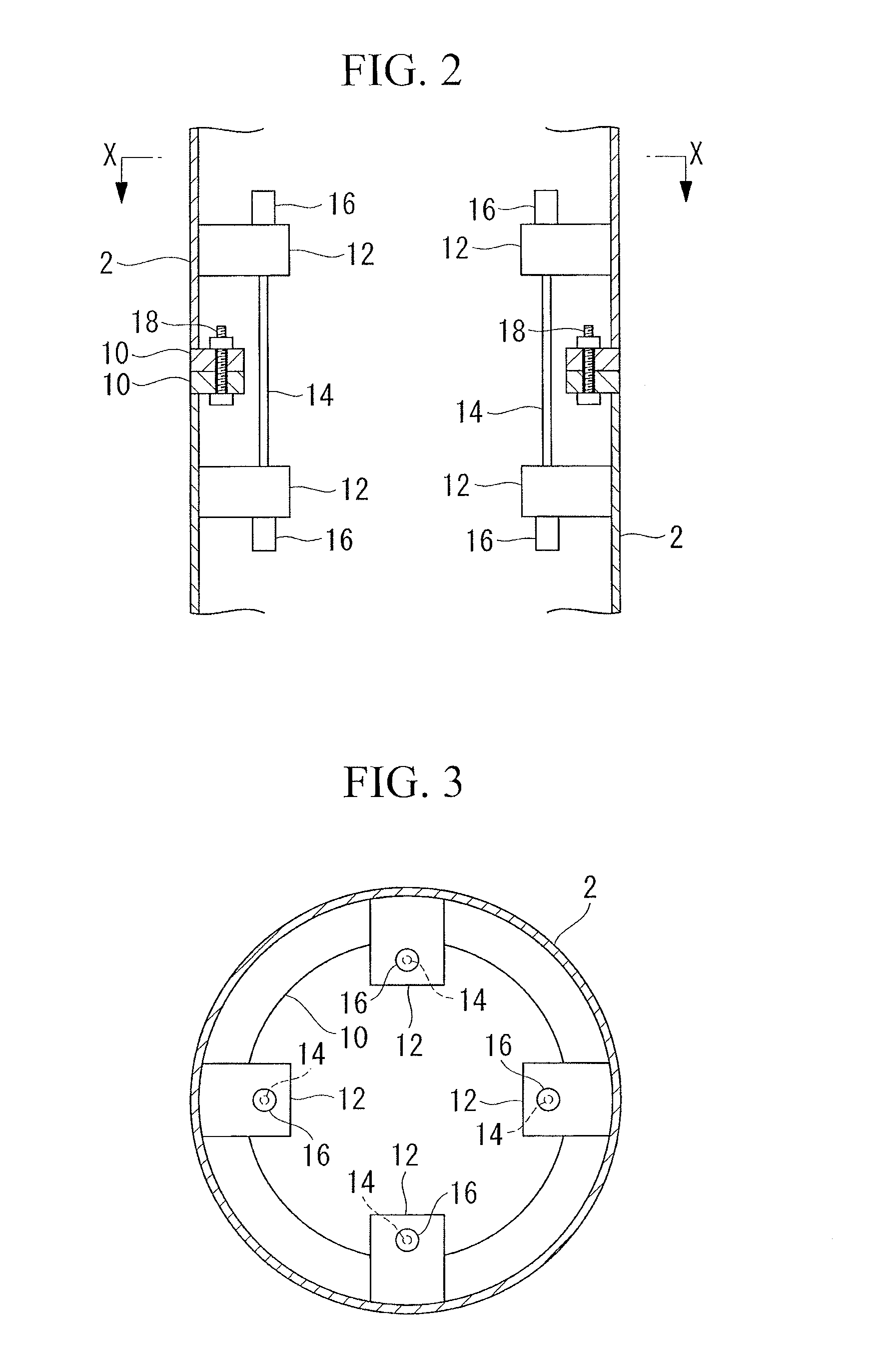

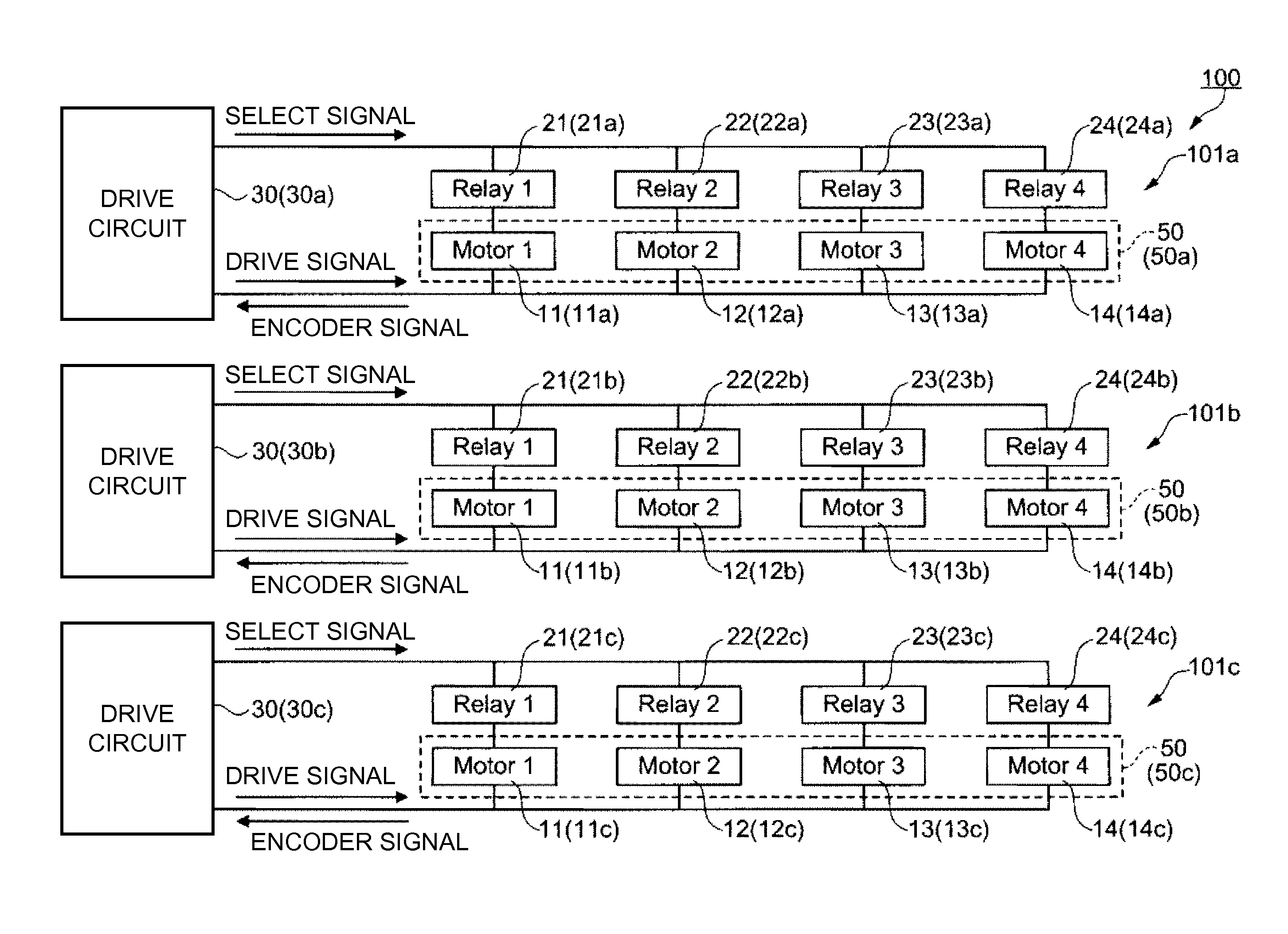

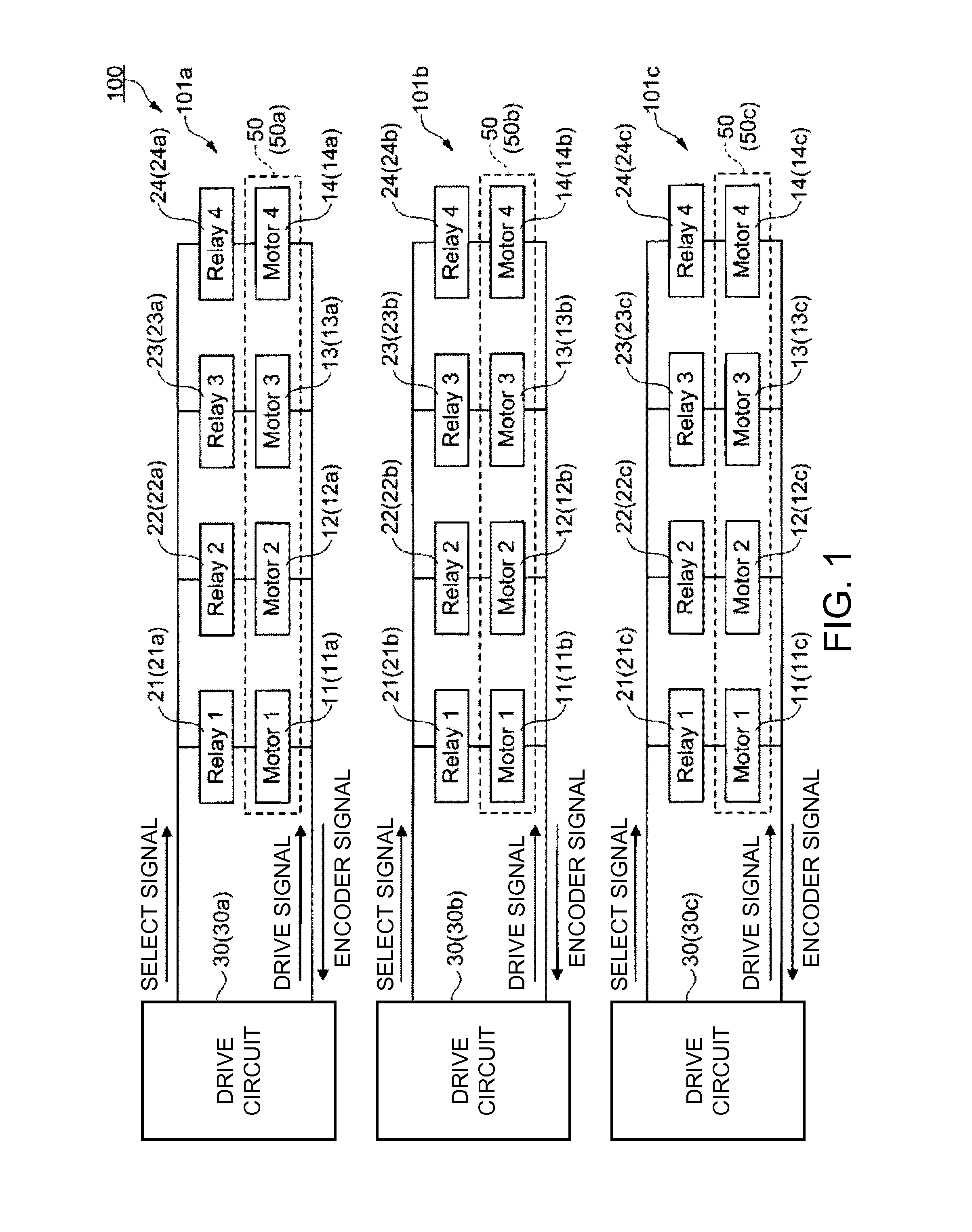

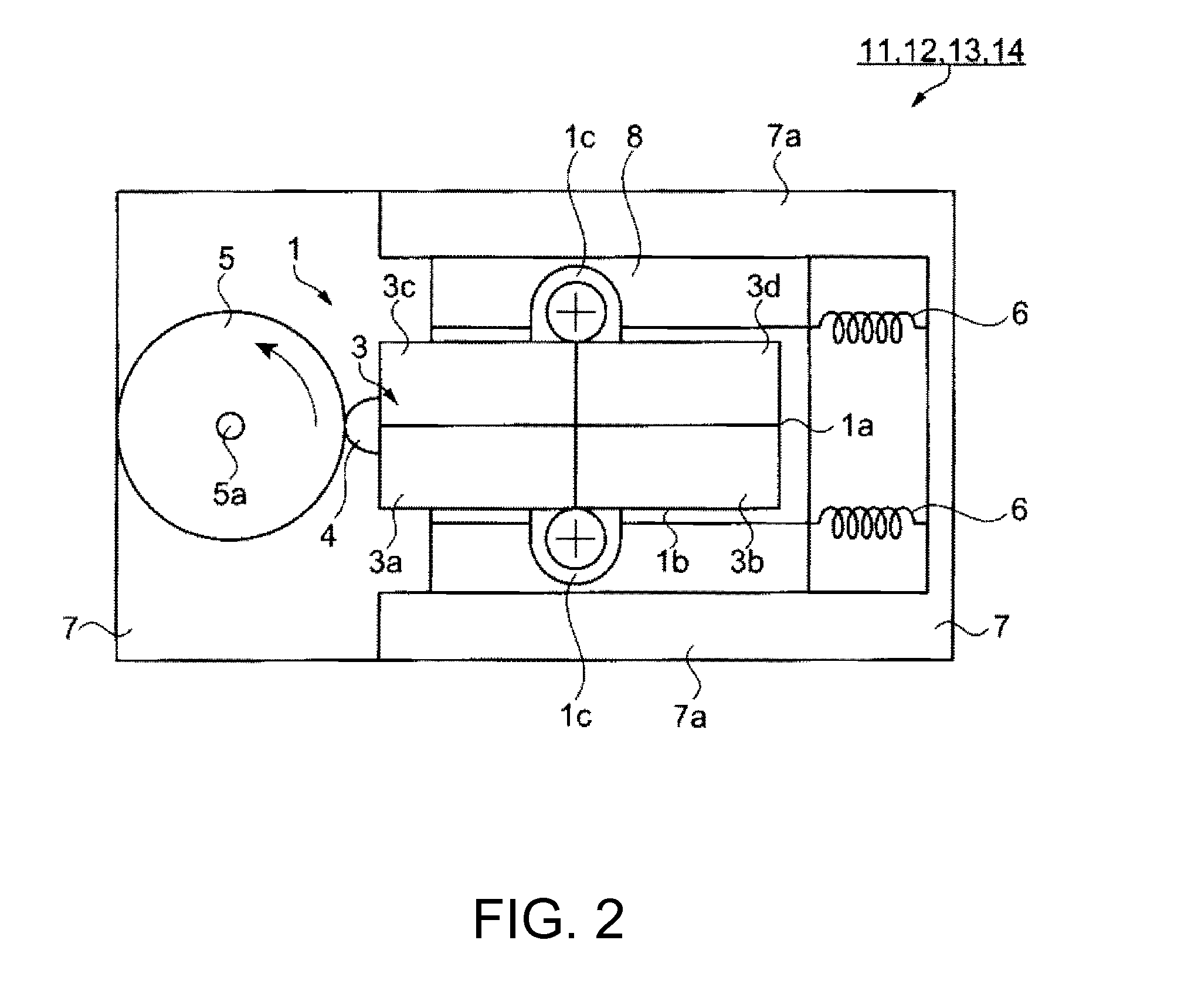

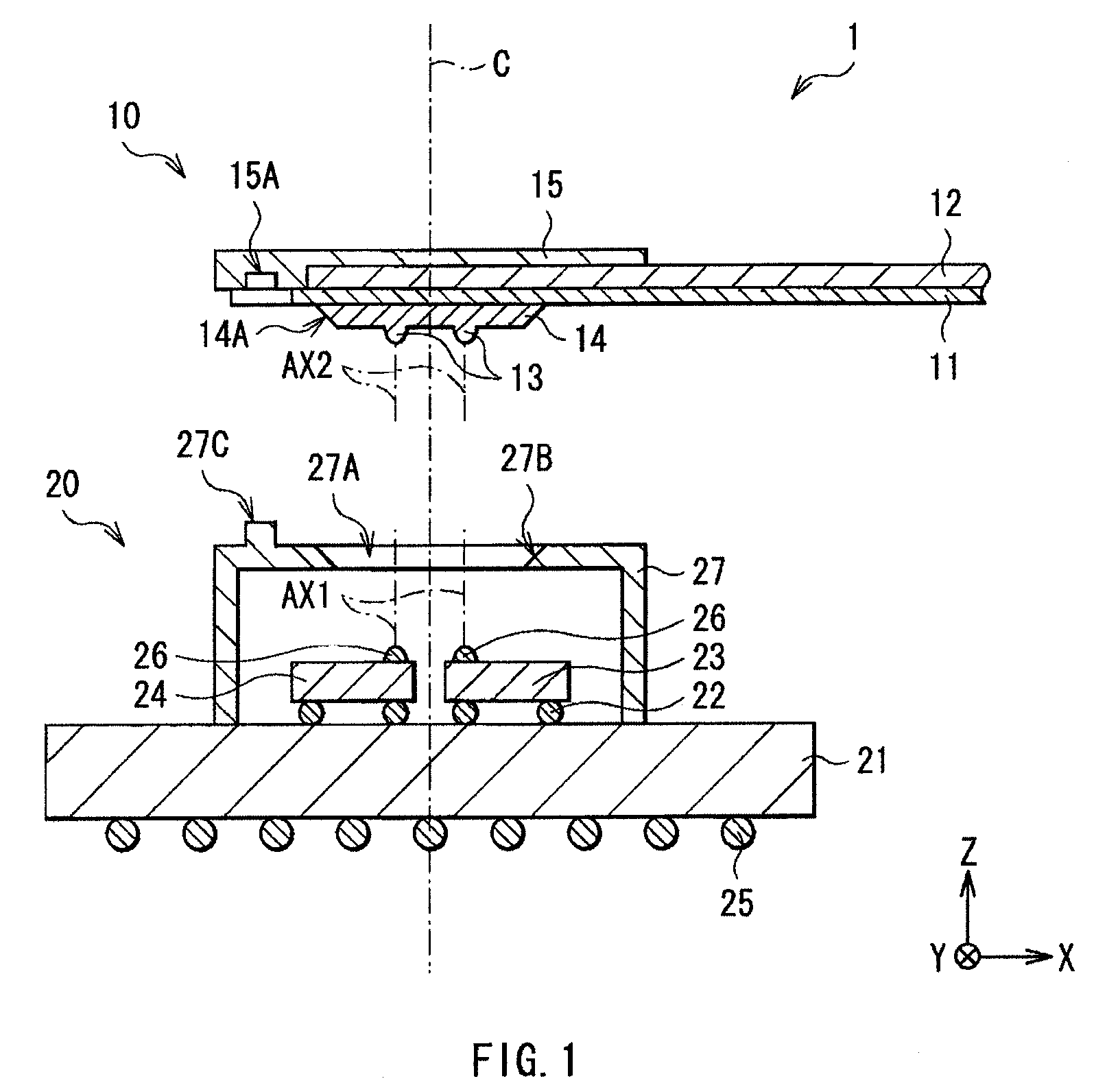

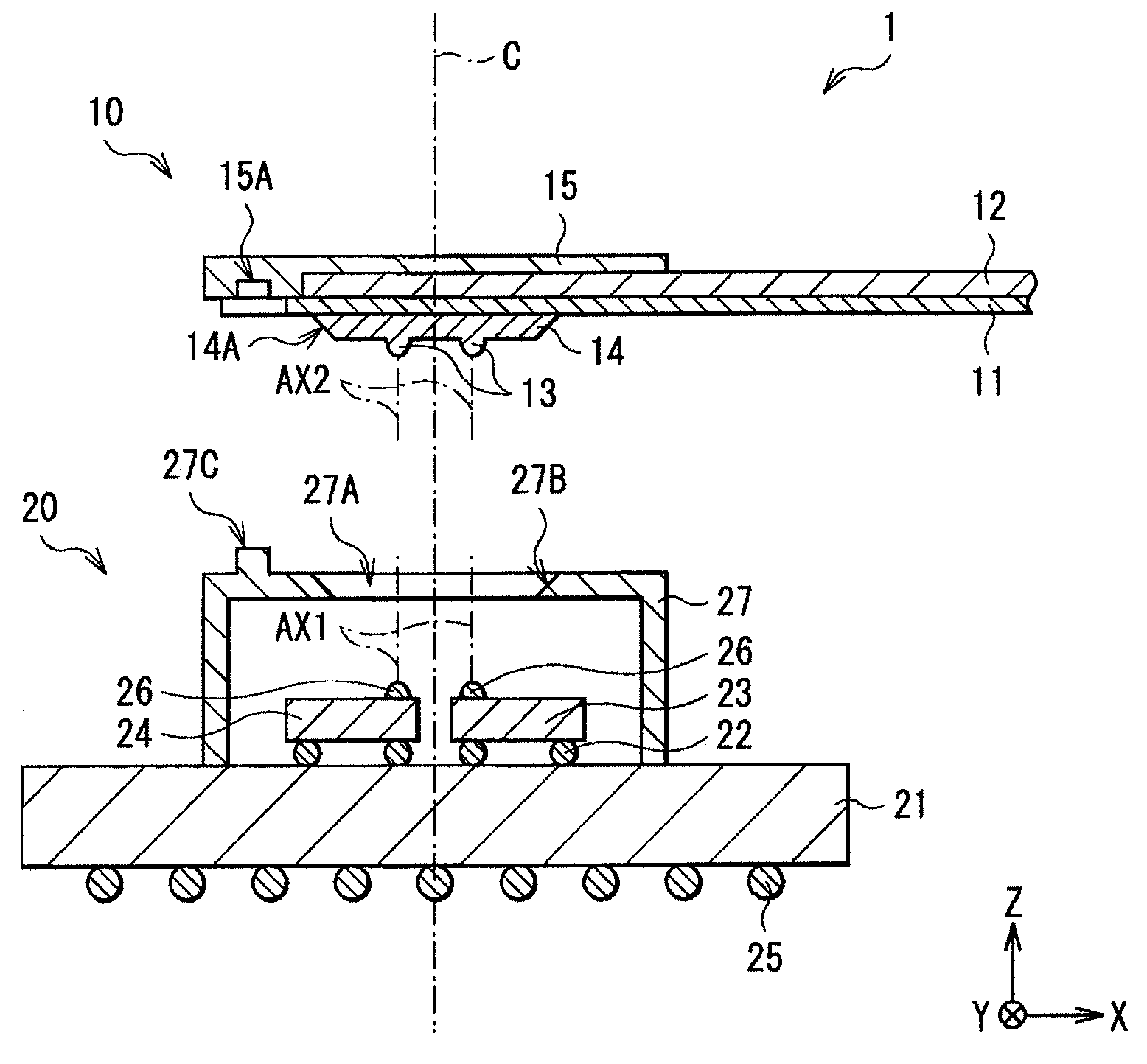

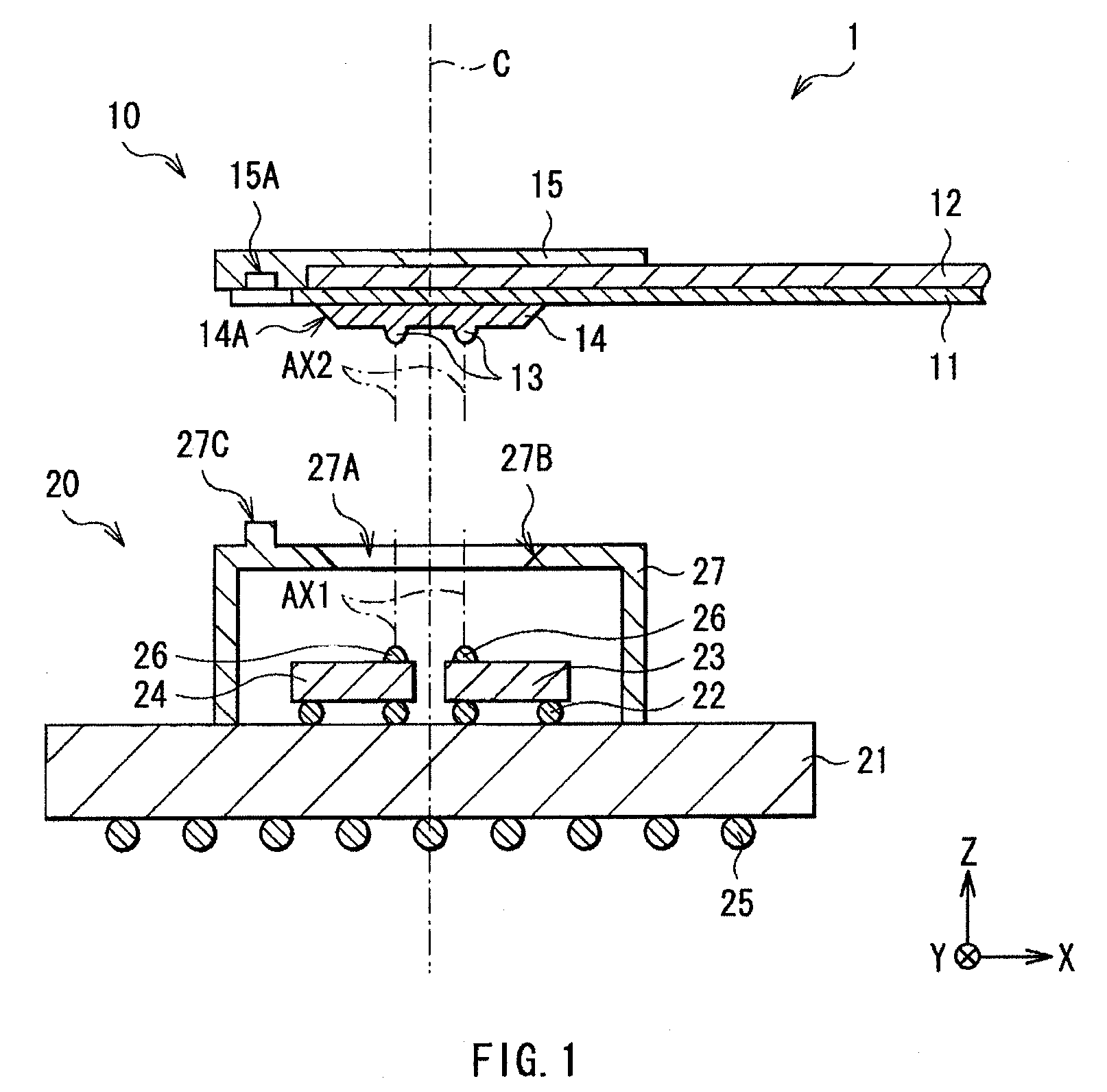

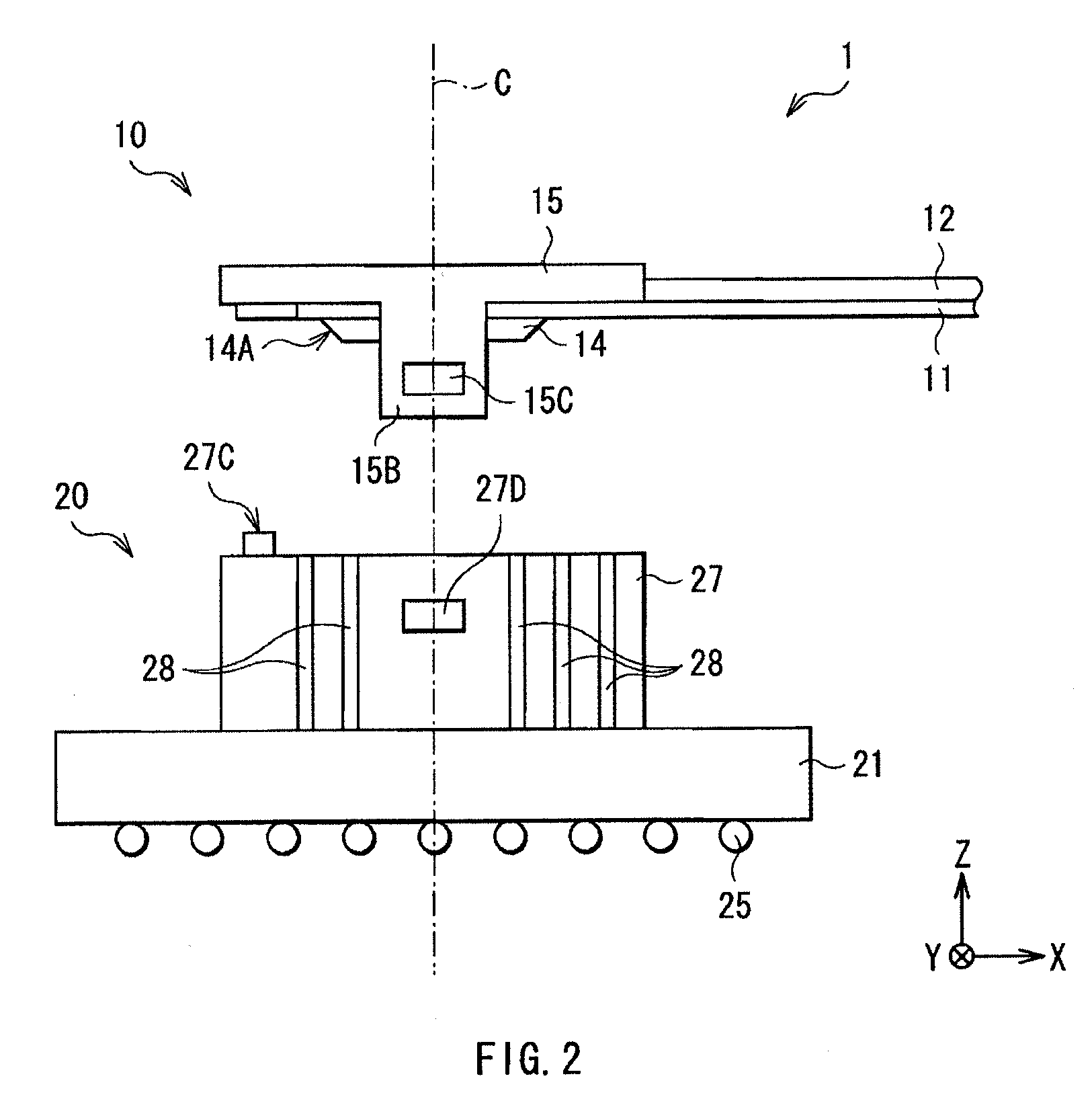

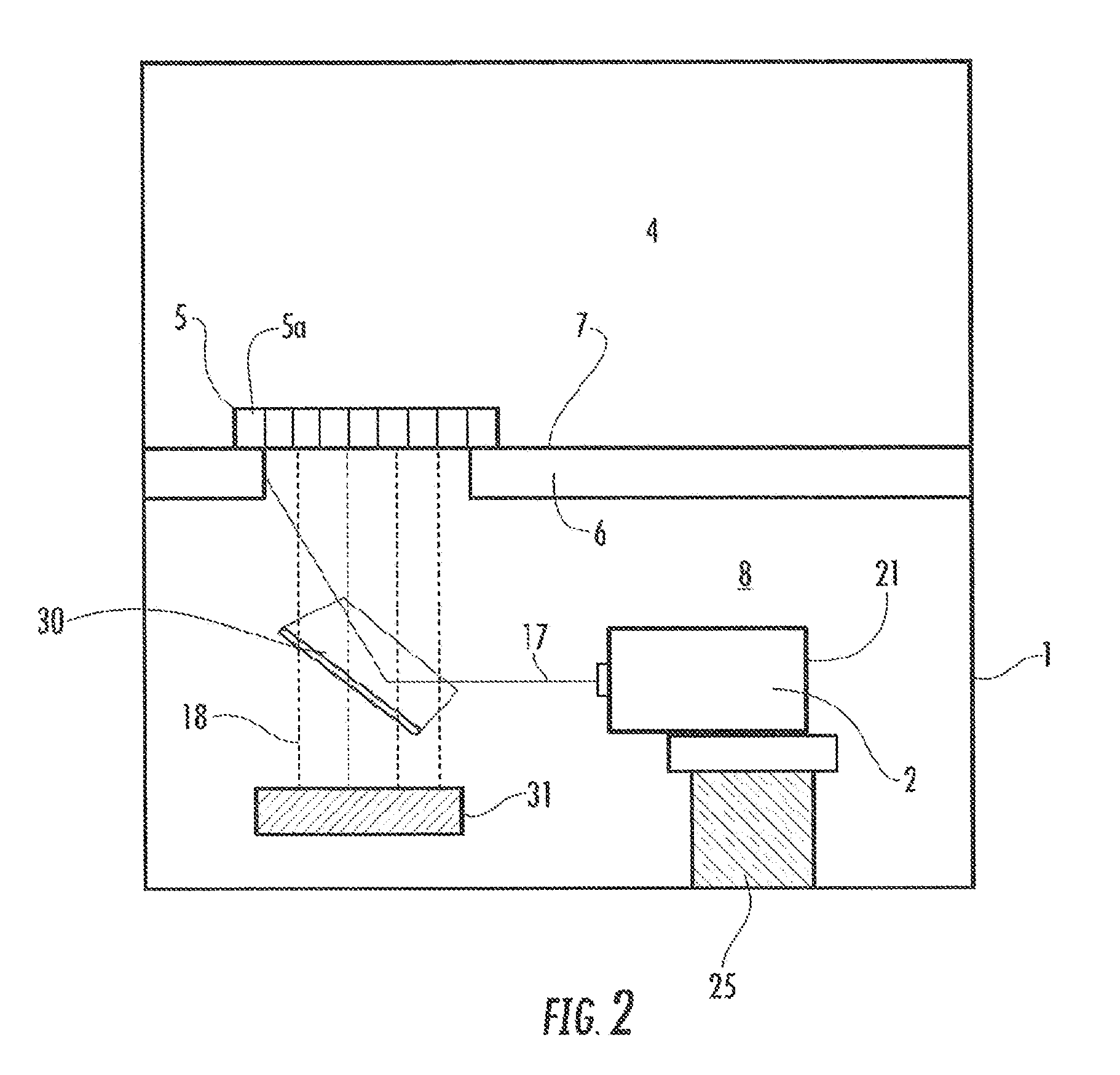

Drive device, electronic component carrying device, electronic component inspection device, robot hand, and robot

InactiveUS20140352459A1Reduction in size and weight and costReduce the numberMechanical apparatusMeasurement devicesRobot handElectronic component

Owner:SEIKO EPSON CORP

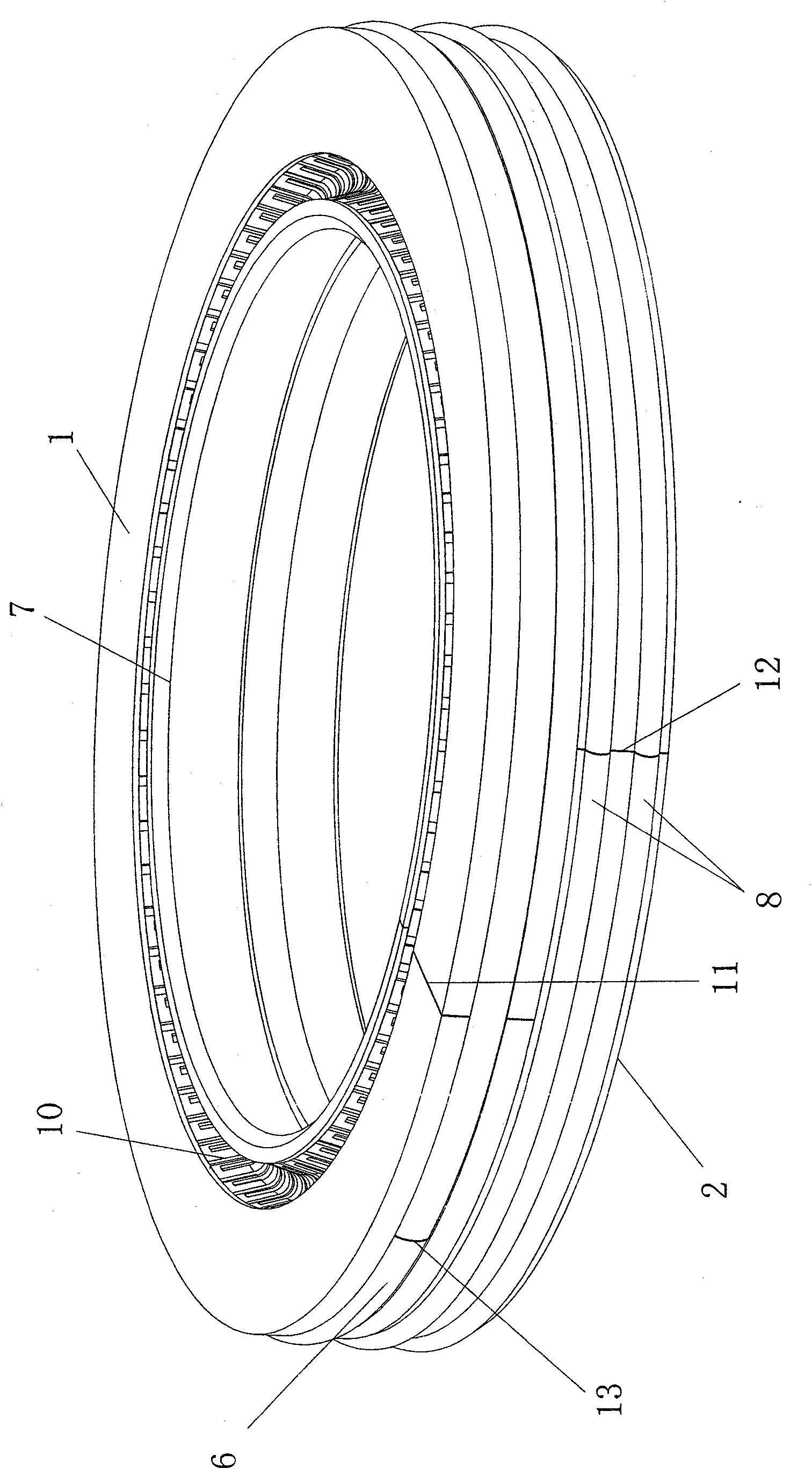

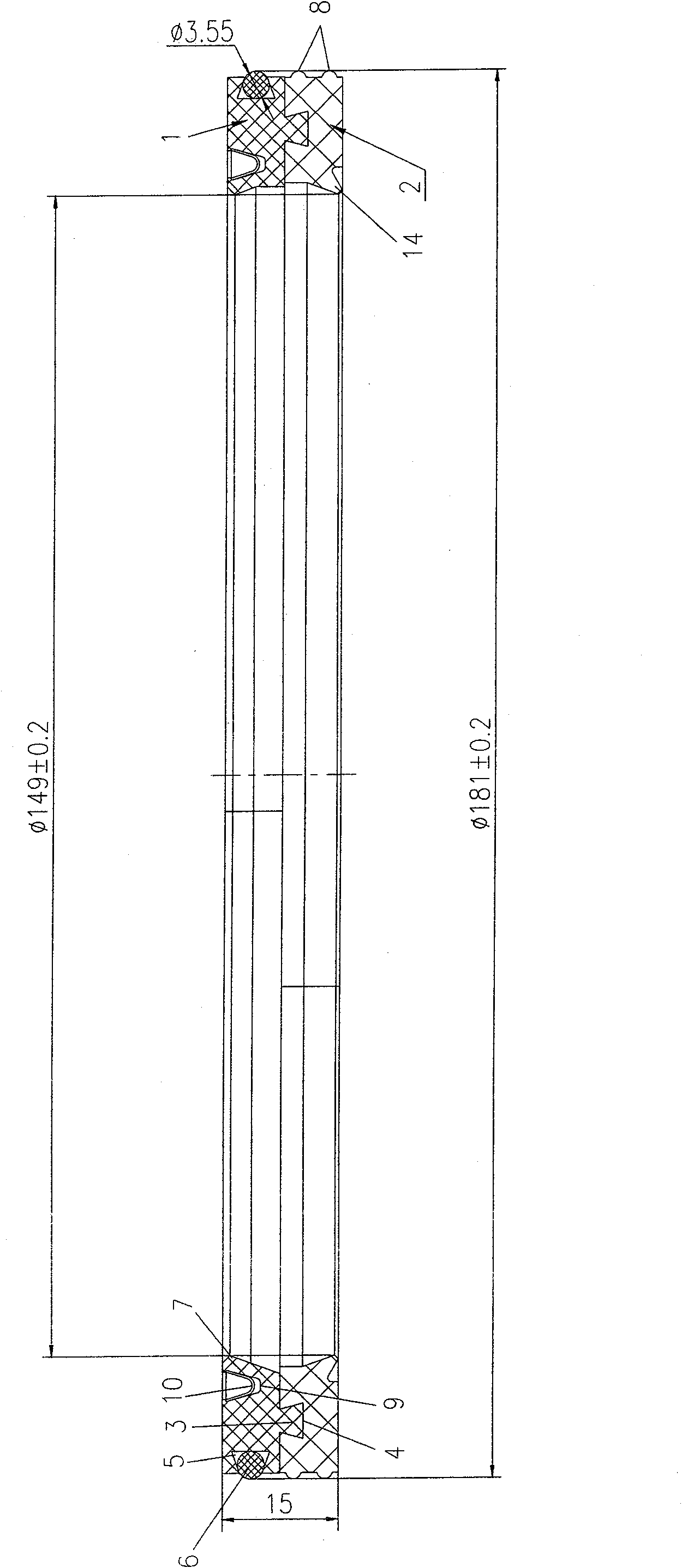

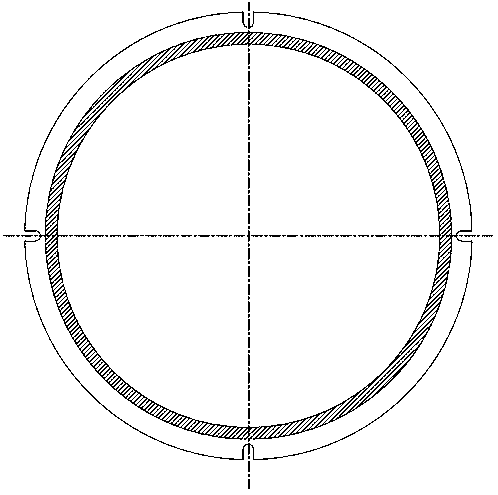

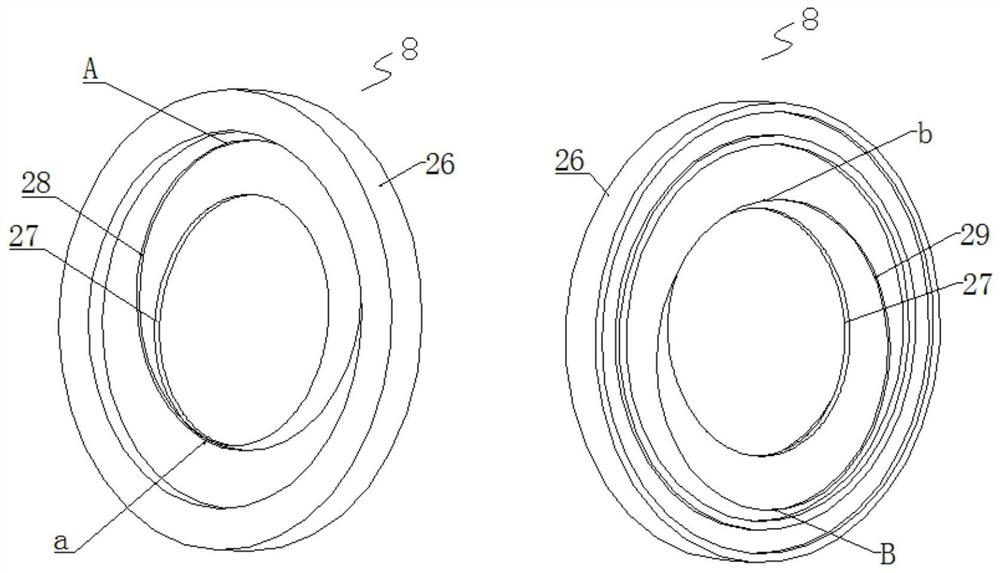

Rockwell sealing ring and production method thereof

The invention discloses a Rockwell sealing ring comprising a main sealing ring and a secondary sealing ring which are parallel to each other, wherein the main sealing ring is connected with the secondary sealing ring in an embedding mode. A groove is disposed at the outer peripheral surface of the main sealing ring, and an elastic ring is embedded in the groove. A sealing main lip is arranged on the inner peripheral surface of the main sealing ring. The invention also discloses a production method of the Rockwell sealing ring. With the advantages of simple structure and convenient processing, the Rockwell sealing ring can enhance processing efficiency and reduce processing cost.

Owner:GUANGZHOU MECHANICAL ENG RES INST

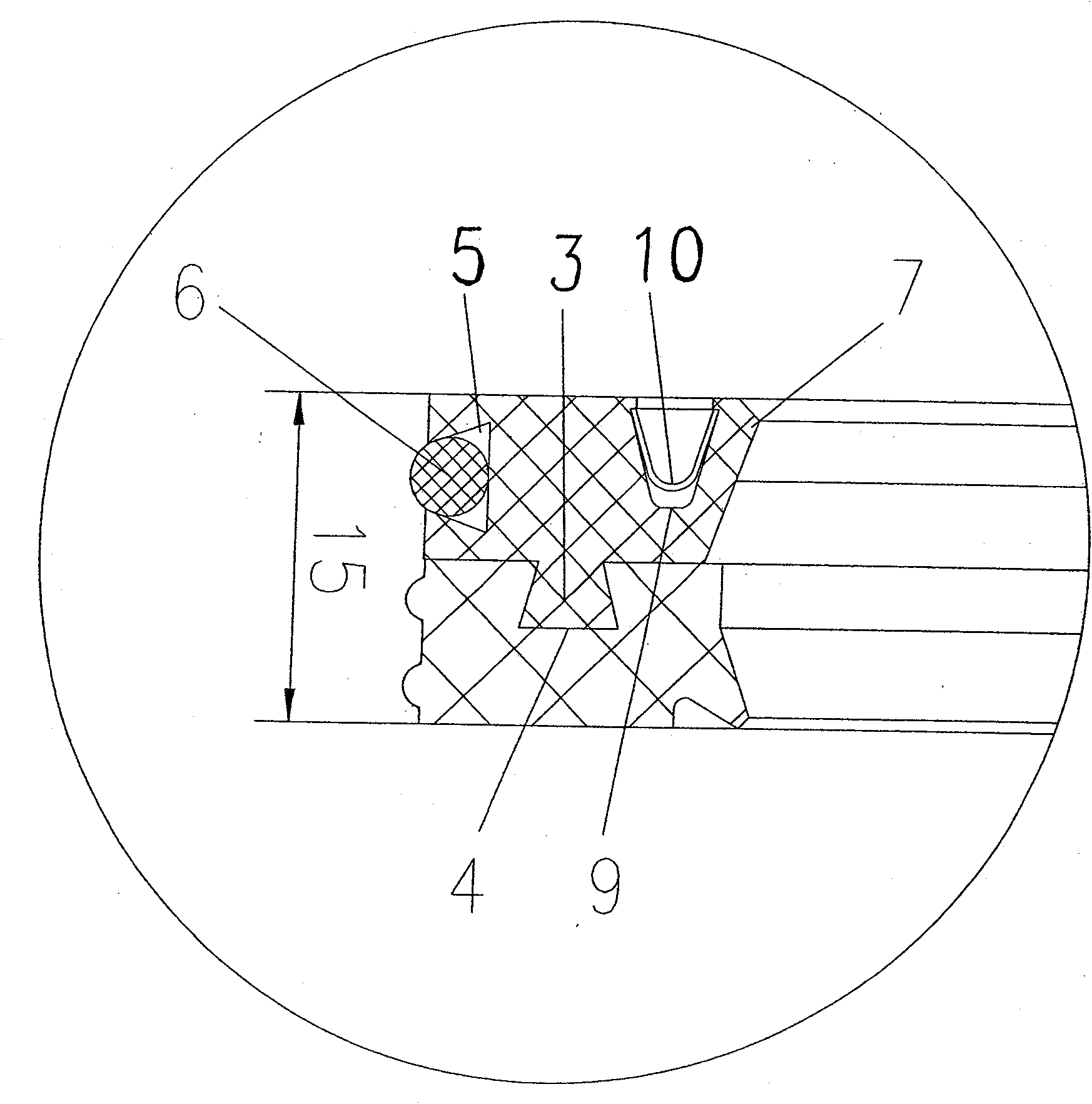

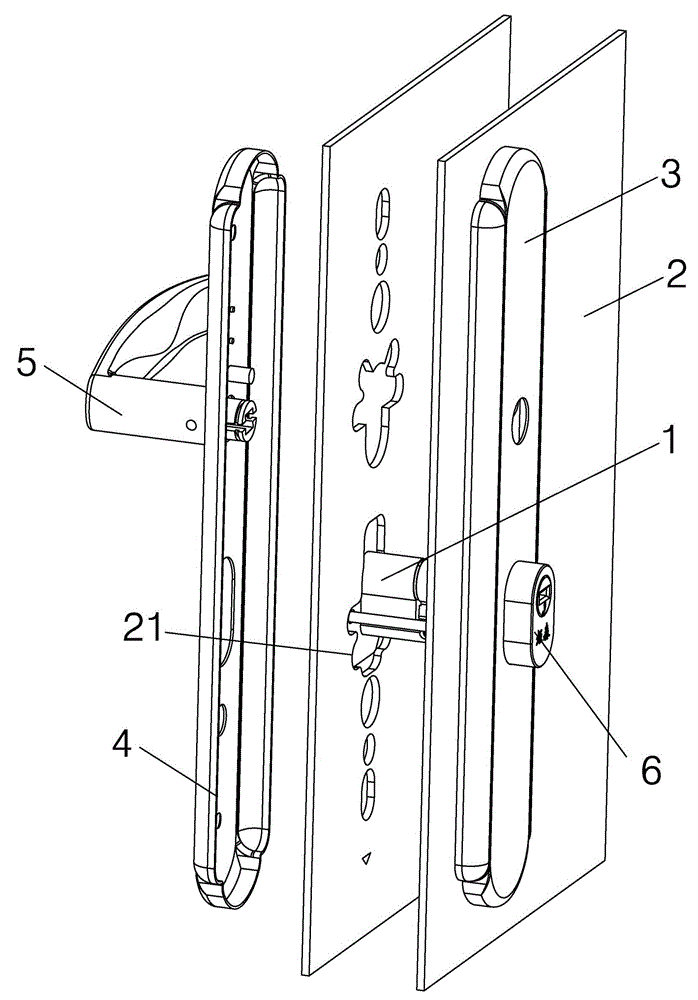

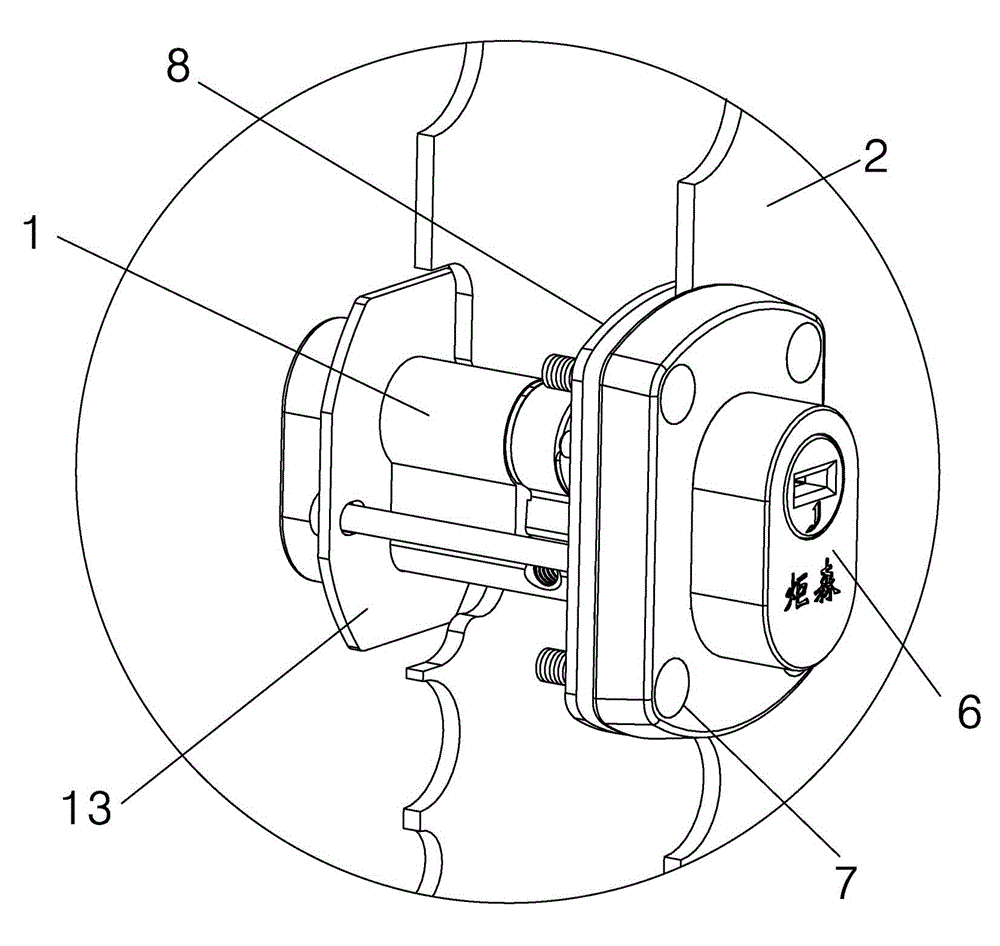

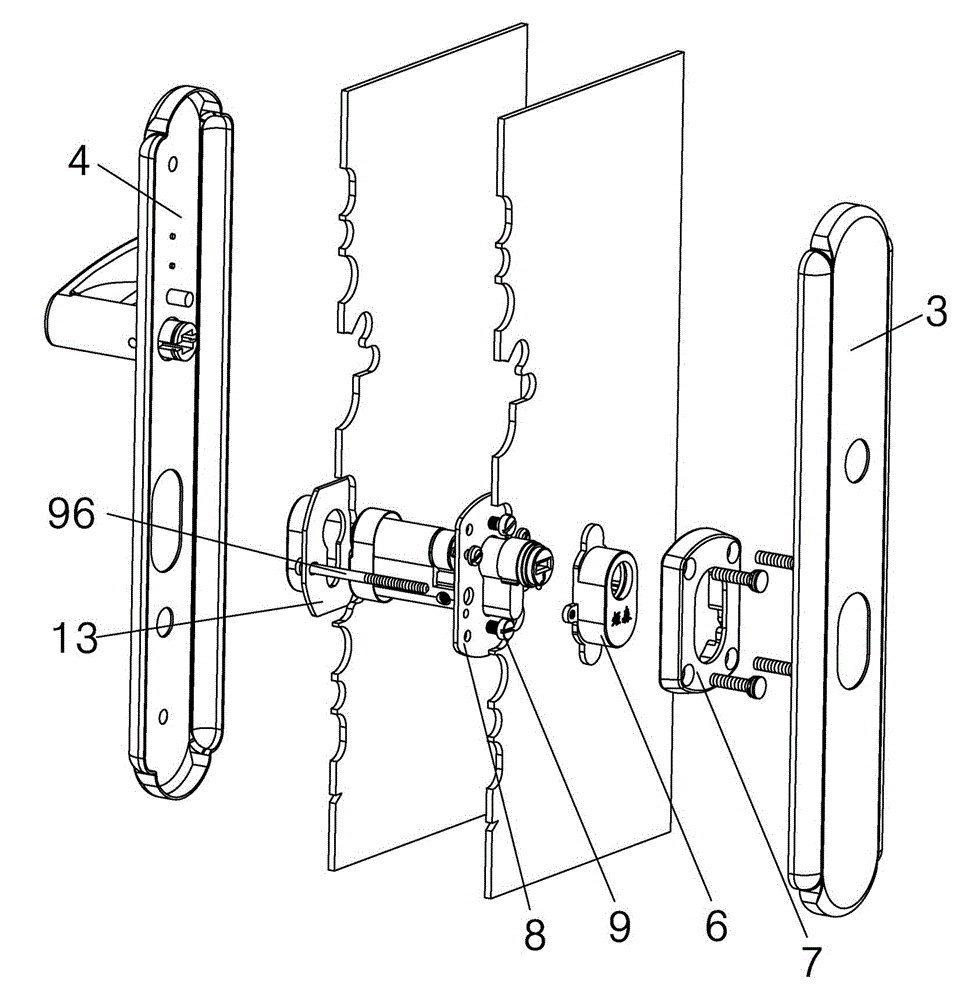

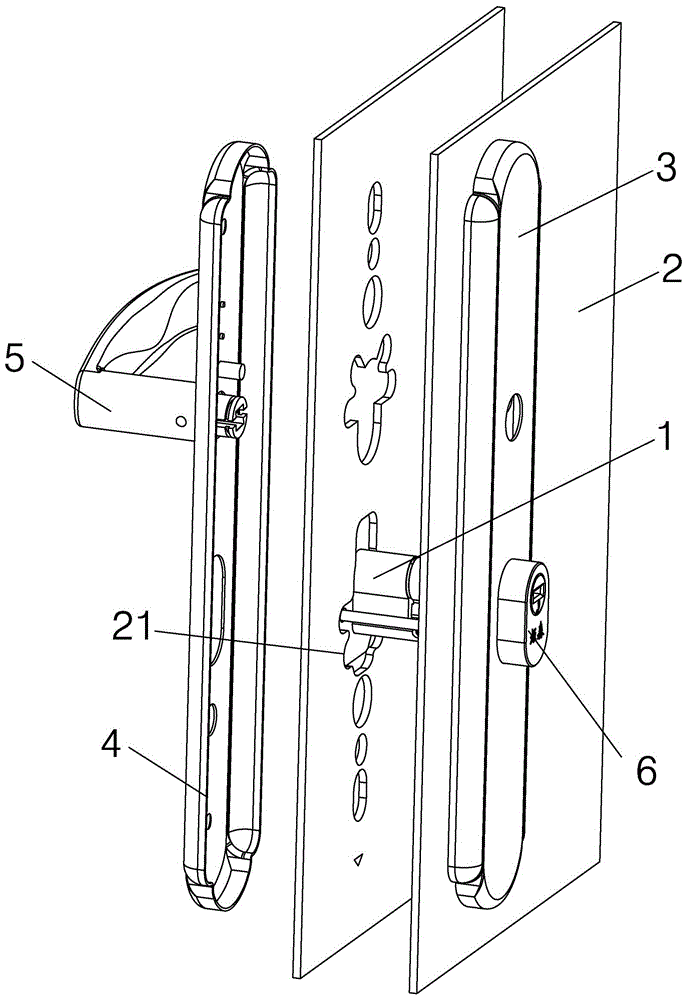

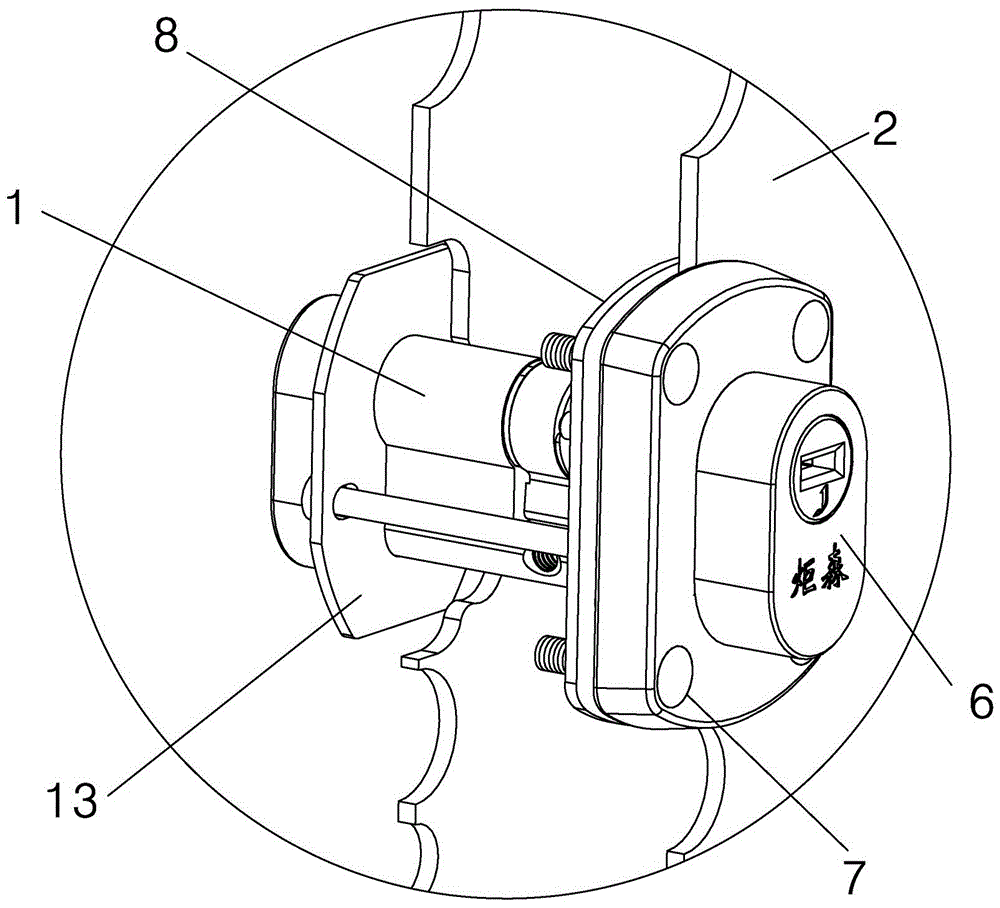

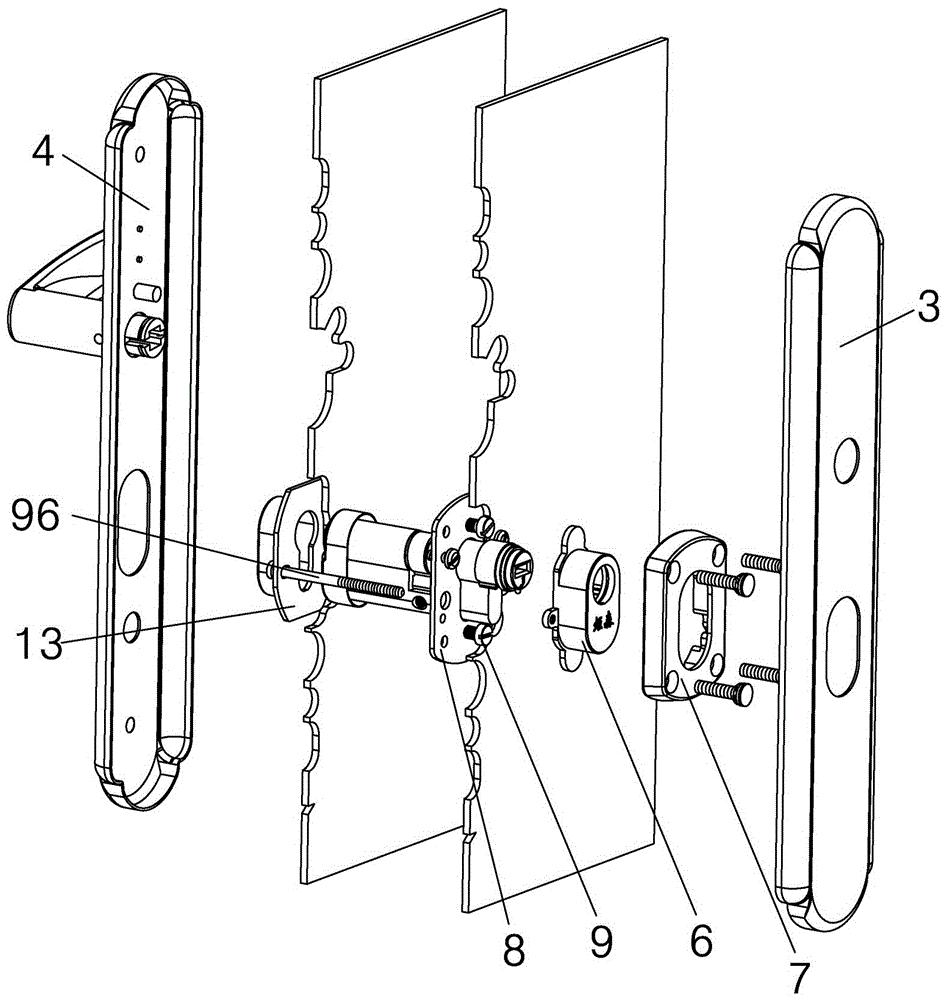

Mortise door lock of adjustable explosion-proof cover

ActiveCN104420713APrecisely adjust the relative distanceImprove working conditionBuilding locksEngineeringScrew joint

Owner:GUANGDONG JUSEN HARDWARE PRECISION MFG

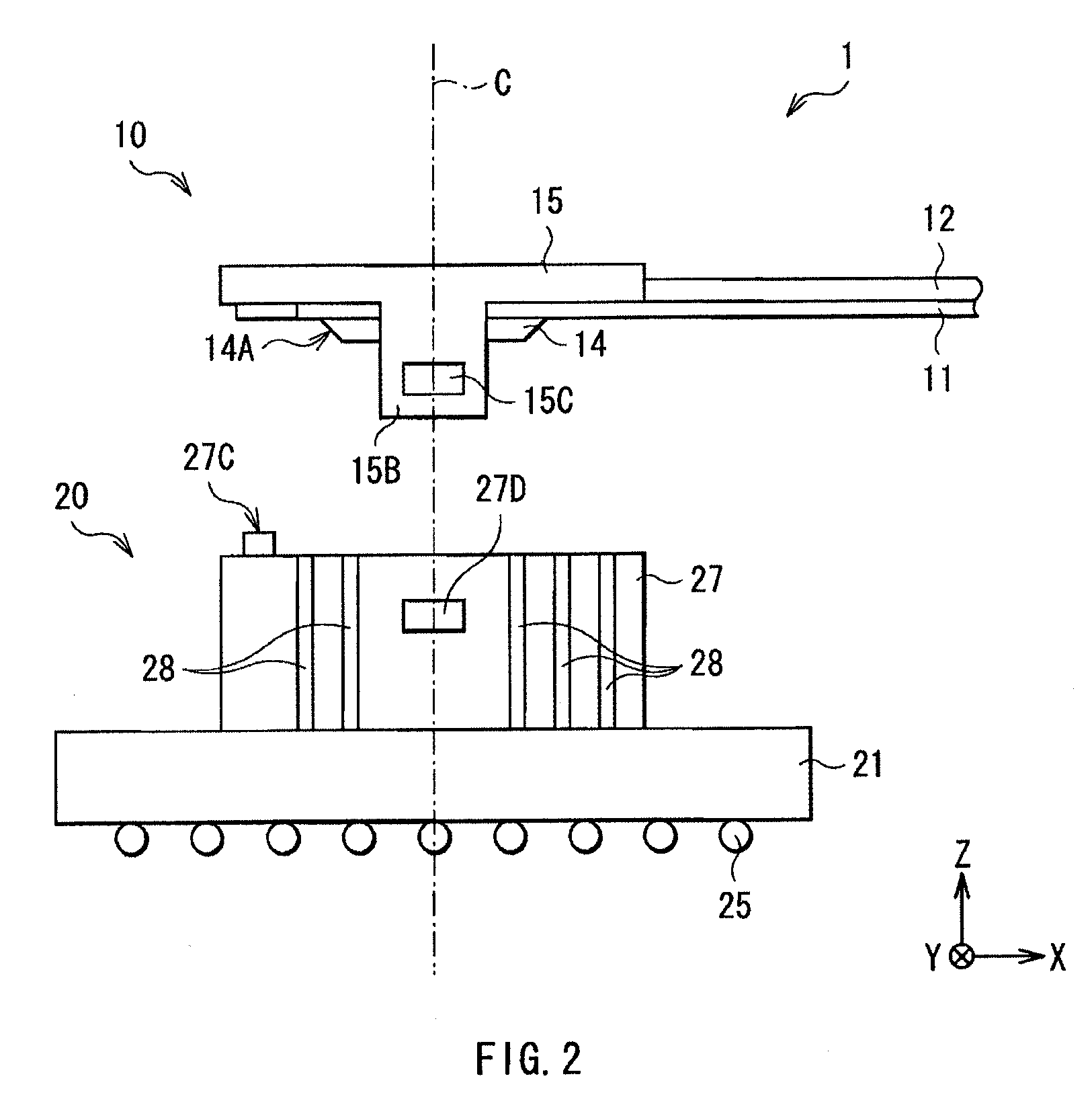

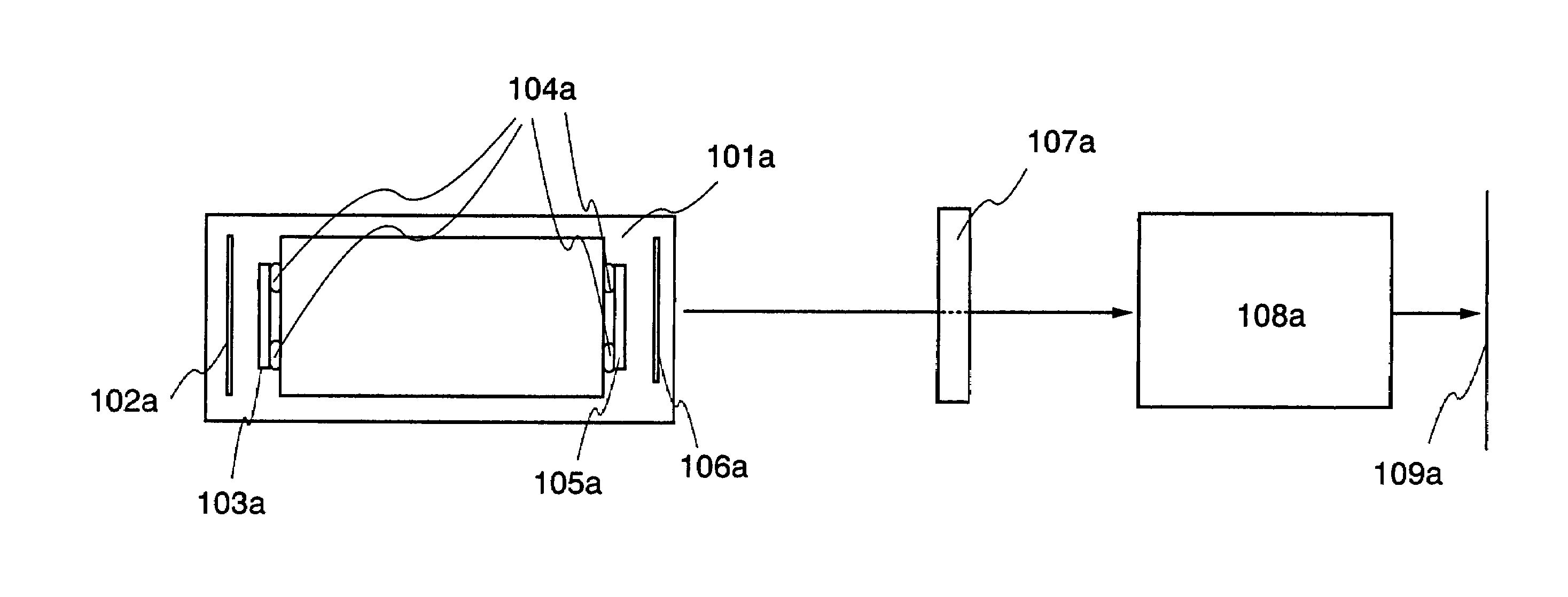

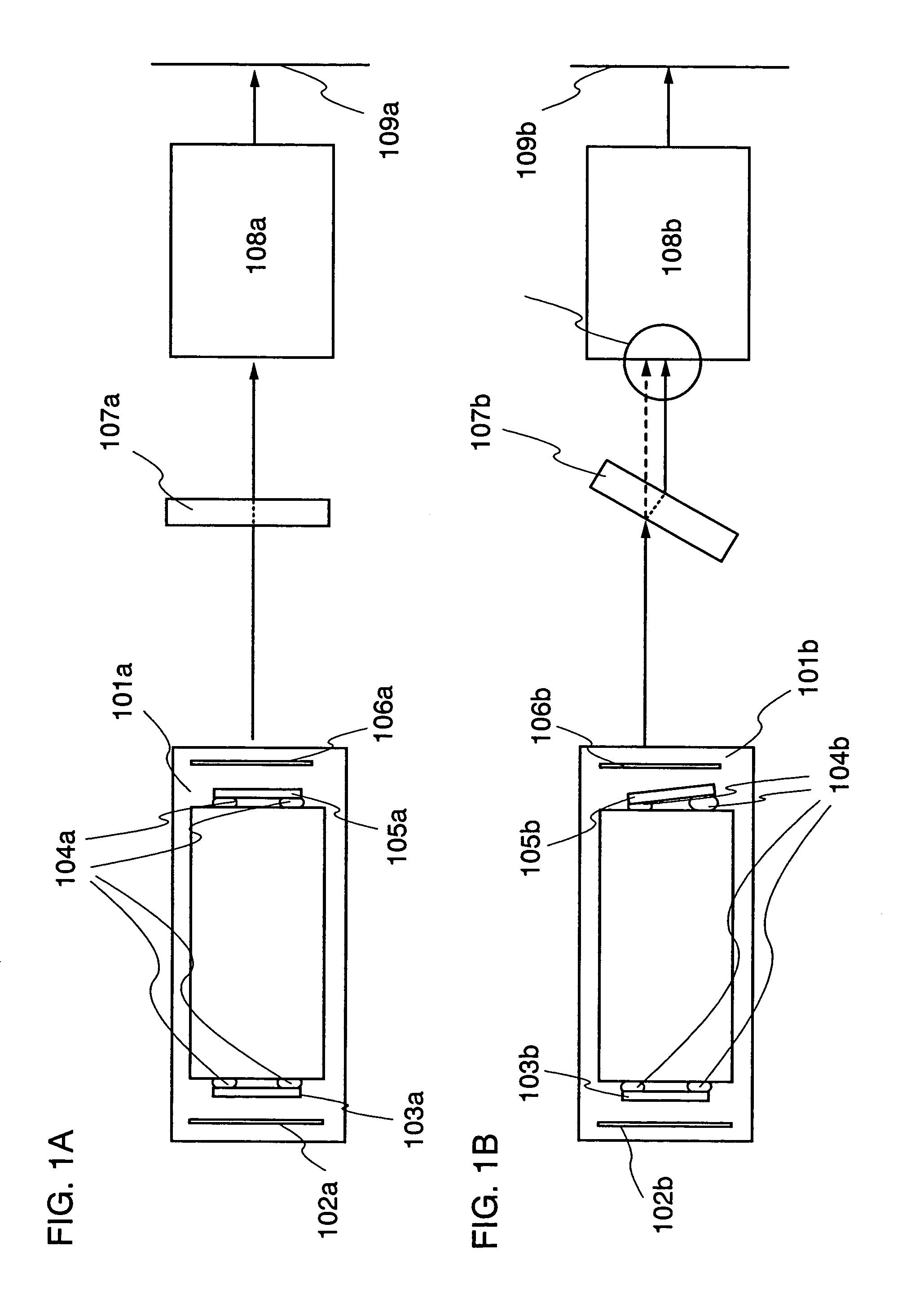

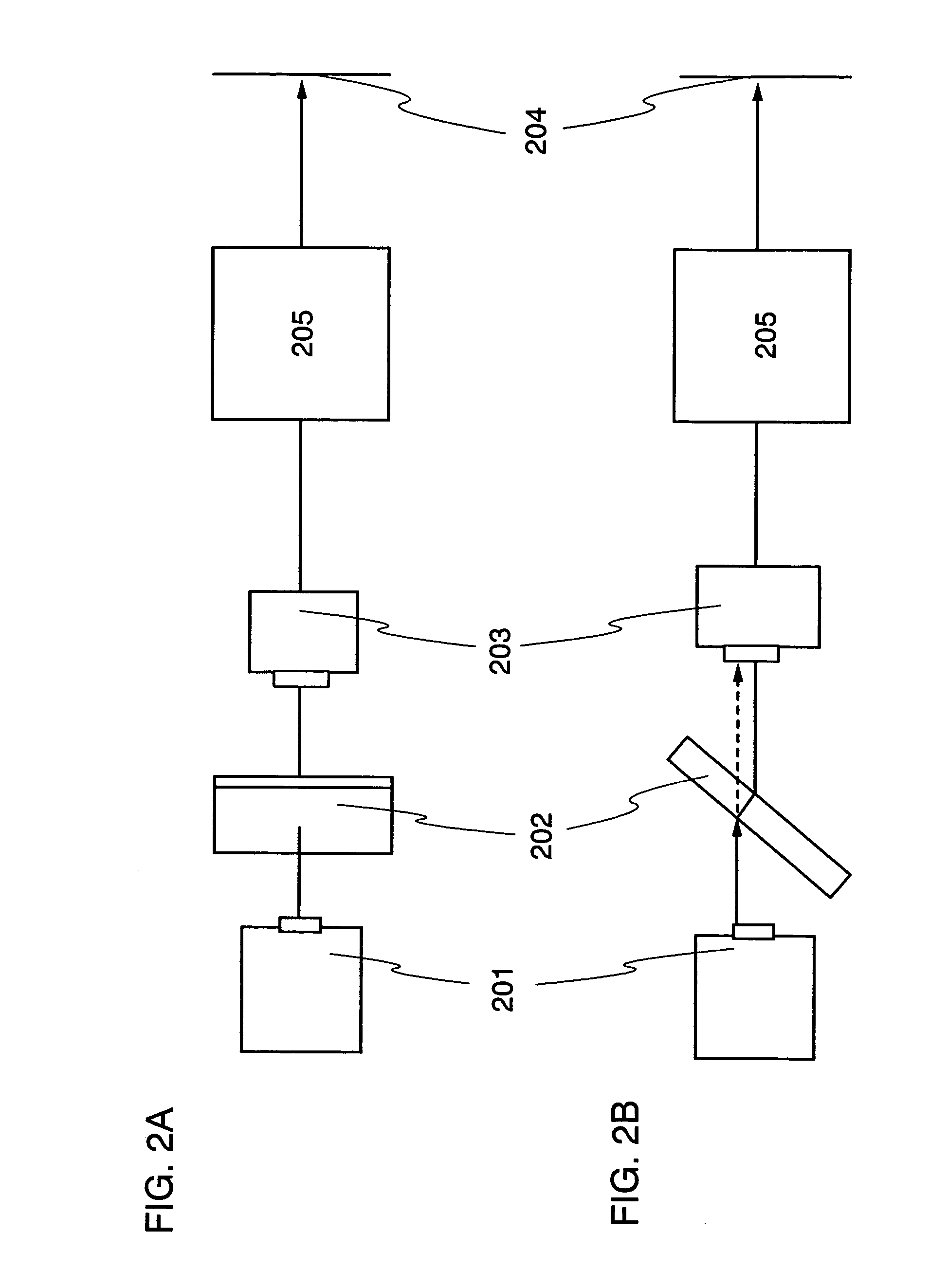

Optical-electrical transmission connector, optical-electrical transmission device and electronic device

ActiveUS7651279B2Easy misalignmentEasily disturbedDetails for portable computersCoupling light guidesOptical axisLight guide

An optical-electrical transmission connector having resistance to optical axis misalignment, having small loss, easily increasing the number of buses, and capable of being formed of a commonly-used material is provided. In a male connector, one collimating lens facing the other collimating lens when connecting the male connector to a female connector is arranged, and a light guide is arranged corresponding to the focal point of the one collimating lens. A positioning section is arranged corresponding to surroundings of the one collimating lens, and the positioning section has one inclined surface coming into contact with the other inclined surface when connecting the male connector to the female connector.

Owner:SONY CORP

Display apparatus and method of manufacturing the same

InactiveUS9869892B2Reduce misalignmentReduce display defectsNon-linear opticsIdentification meansEngineering

A display apparatus includes a display panel and a mold frame. The display panel includes a display area, a peripheral area surrounding the display area, an alignment mark on the peripheral area, and a cover element overlapping the alignment mark to cover the alignment mark. The mold frame has a frame shape configured to receive the display panel. The mold frame includes a panel guide protrusion protruding from an inner surface of the mold frame, and the panel guide protrusion is adjacent to the alignment mark.

Owner:SAMSUNG DISPLAY CO LTD

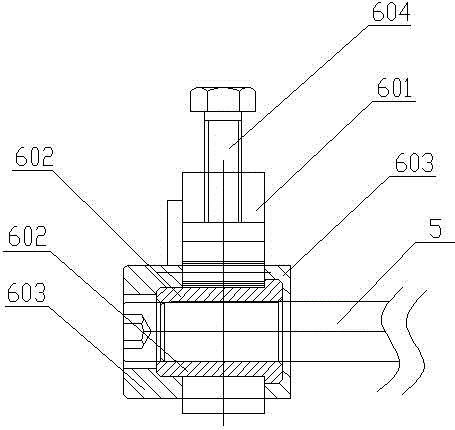

Integrated hard sealing diaphragm of diaphragm compressor

PendingCN110529370AEasy misalignmentEasy to usePositive displacement pump componentsFlexible member pumpsMachining processSafety valve

The invention discloses an integrated hard sealing diaphragm of a diaphragm compressor. A layer of copper alloy is directly electroplated on the process side diaphragm and the oil side diaphragm in anelectroplating manner. A layer of copper alloy is directly electroplated on a diaphragm in an electroplating mode, an electroplated layer serves as hard seal, can replace an O-shaped ring and servesas a sealing material, the copper alloy has certain ductility, the air cylinder can have certain deformation under the fastening of a bolt, the deformed electroplated layer can be tightly attached tothe upper air cylinder and the lower air cylinder, and the sealing effect is achieved. The process side diaphragm and the oil side diaphragm are provided with positioning holes, so that the installation is convenient, the diaphragm installation precision is improved, and the diaphragm displacement is prevented; the buffer layer is provided with a crack arrest hole and an unloading groove; the unloading groove can rapidly transmit leaked gas to a pressure sensor or a pressure gauge or a safety valve arranged in the leakage detection hole, the purpose of rapid detection is achieved, the crack stopping hole can prevent the unloading groove in the buffer layer from cracking, the service life of the buffer layer is prolonged, and the machining difficulty of the buffer layer in the unloading groove machining process is lowered.

Owner:SICHUAN JINXING CLEAN ENERGY EQUIP CO LTD

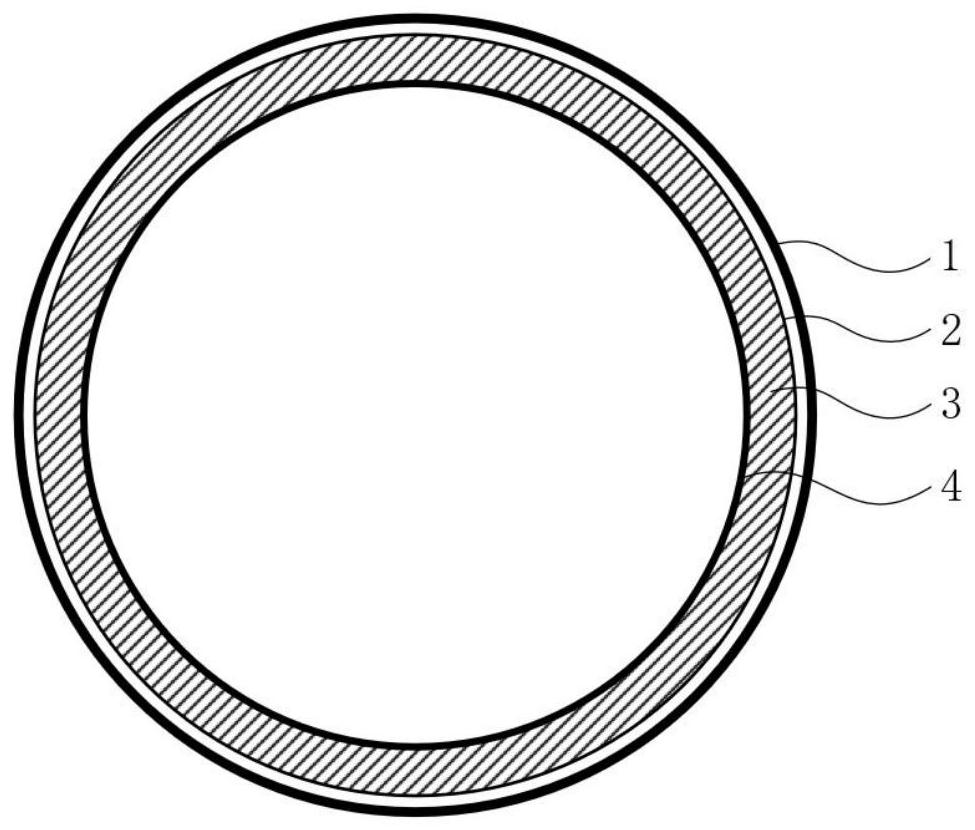

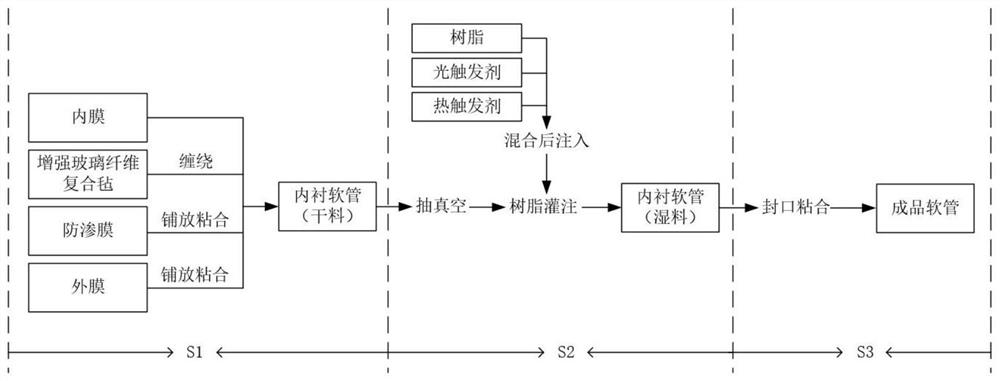

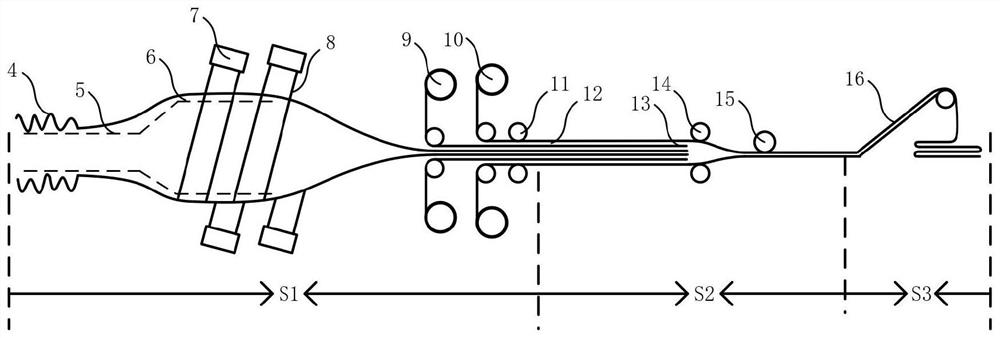

Ultraviolet curing pipeline repair lining hose and winding type production process thereof

PendingCN113459354AEasy misalignmentLow application costTubular articlesLap jointProcess engineering

The invention relates to the field of trenchless pipeline repair, discloses an ultraviolet curing pipeline repair lining hose and a winding type production process thereof, and breaks through the current situation of discontinuous production of manual lap joint and dry material manufacturing and glue injection processes at present. The process comprises the following three steps of: winding to manufacture a pipe, injecting glue in vacuum, and stacking and packaging. The first step comprises an inner film nesting unit, a winding unit and a wrapping and bonding unit. The second step comprises a vacuum unit, a glue injection unit and a rolling unit. The winding type production process has the advantages that the dry material hose is manufactured through winding, the problem that sheets at the lap joint position are prone to dislocation due to lap joint manufacturing in a traditional process is effectively solved, and the mechanical strength is easily guaranteed after curing; in cooperation with dry material winding, resin is injected in a vacuum infusion mode; and compared with traditional resin impregnation, the mode can quantitatively control the resin fiber ratio and is more uniform in impregnation. The continuous production process can greatly improve the production efficiency and reduce the application cost of raw materials, and the product is high in application strength and controllable in quality.

Owner:HARBIN UNIV OF SCI & TECH

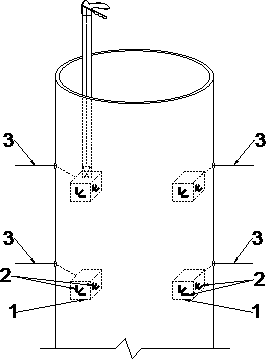

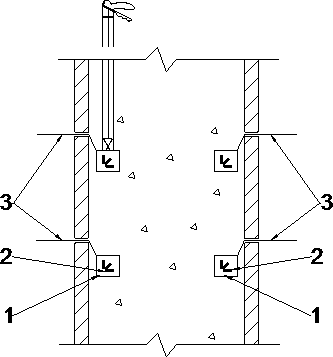

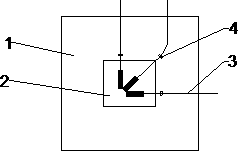

Internal strain monitoring device and method for steel pipe concrete

InactiveCN109115170ATrue reflection of strainEliminate disturbanceMeasurement devicesData acquisitionEngineering

The invention discloses an internal strain monitoring device and method for steel pipe concrete. The device is composed of a strain sensing module, a positioning module and a data collection module; the strain sensing module is composed of a test base body, a strain rosette, a lead and a binding post; the positioning module is composed of a positioning pipe, a fixed handle, a movable handle, a torsion spring, a line ranger, an extended positioning rod, a wire rope, a rotating shaft, a spring and a calibrated scale; and the data collection module is composed of a data collector and a computer.The test base body is fixed in a predetermined position by the positioning module, the fixed handle is rotated to adjust the angle of the test base body, and concrete is placed and maintained; and thestrain of the test base body is monitored, and further strain in the predetermined position in the steel pipe concrete is monitored. The test base body is positioned accurately via the positioning module, disturbance of concrete placement to the position of the strain sensing module is eliminated, the problem that a present strain test component tends to offset in a sample is solved, and the device and method can be widely applied to the field of internal strain monitoring and test of concrete.

Owner:SHANDONG UNIV OF SCI & TECH

Optical-electrical transmission connector, optical-electrical transmission device and electronic device

ActiveUS20090196550A1Easy to produceEasily disturbedDetails for portable computersCoupling light guidesLight guideOptical axis

An optical-electrical transmission connector having resistance to optical axis misalignment, having small loss, easily increasing the number of buses, and capable of being formed of a commonly-used material is provided. In a male connector, one collimating lens facing the other collimating lens when connecting the male connector to a female connector is arranged, and a light guide is arranged corresponding to the focal point of the one collimating lens. A positioning section is arranged corresponding to surroundings of the one collimating lens, and the positioning section has one inclined surface coming into contact with the other inclined surface when connecting the male connector to the female connector.

Owner:SONY CORP

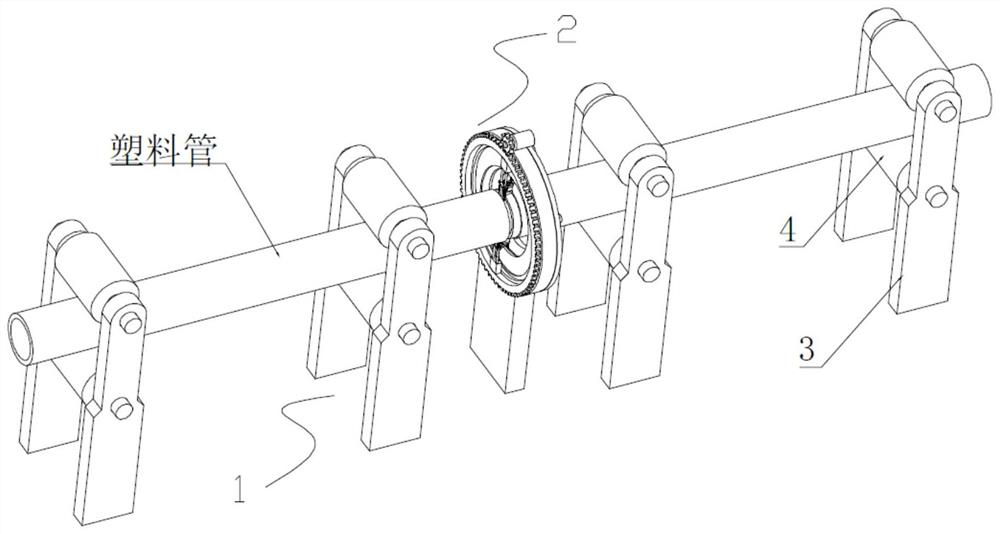

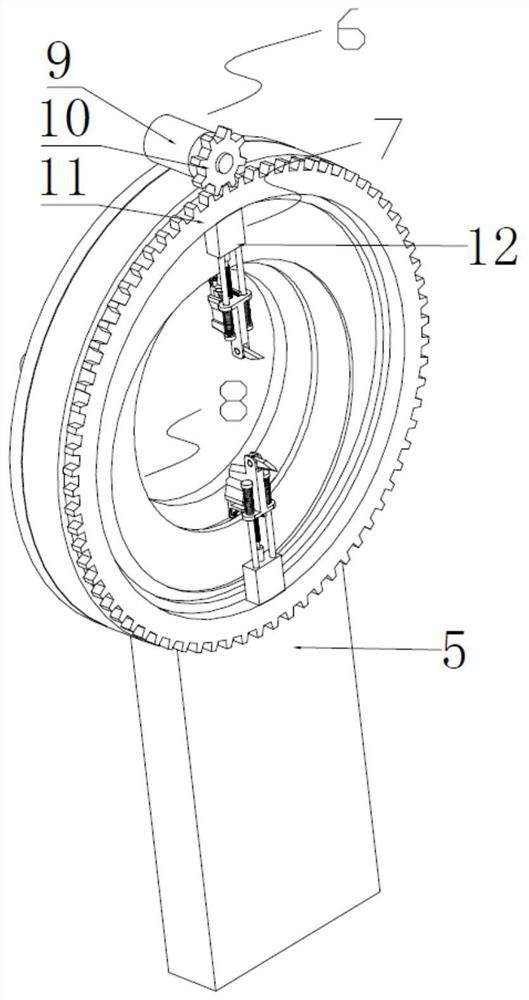

Plastic pipe cutting device for plastic extruding machine

ActiveCN113580242ASolve the bending phenomenonLevel avoidMetal working apparatusAdhesive beltStructural engineering

The invention discloses a plastic pipe cutting device for a plastic extruding machine, and relates to the field of cutting devices. The plastic pipe cutting device comprises multiple sets of conveying roller assemblies of the same structure and a cutting device, the multiple sets of conveying roller assemblies are symmetrically distributed on the two sides of the cutting device and used for conveying plastic pipes, and the cutting device comprises a base, a driving assembly, a cutting assembly and a rail assembly; and the conveying roller assemblies and the cutting device are arranged, a first rail and a third rail are symmetrically arranged along the center line of a second rail, a first cutter gradually makes contact with one plastic pipe and cuts the plastic pipe, finally the plastic pipe is cut off through rotation, the first cutter cuts the end of the plastic pipe to expand the inner diameter, and a second cutter cuts the outer wall of the end of the adjacent plastic pipe. The plastic pipe with the two ends easy to connect and free of dislocation is finally obtained, and the problems that the end of an existing plastic pipe is flat, dislocation is likely to happen when a worker winds adhesive tape, the axes of every two adjacent plastic pipes are not coaxial, an included angle is formed, and the adjacent plastic pipes after winding are bent are solved.

Owner:芜湖富田电子科技有限公司

Bi-section semiconductor laser device, method for manufacturing the same, and method for driving the same

ActiveUS20120281726A1Easy misalignmentIncrease resistanceOptical wave guidanceLaser detailsResistEtching

Owner:SONY CORP +1

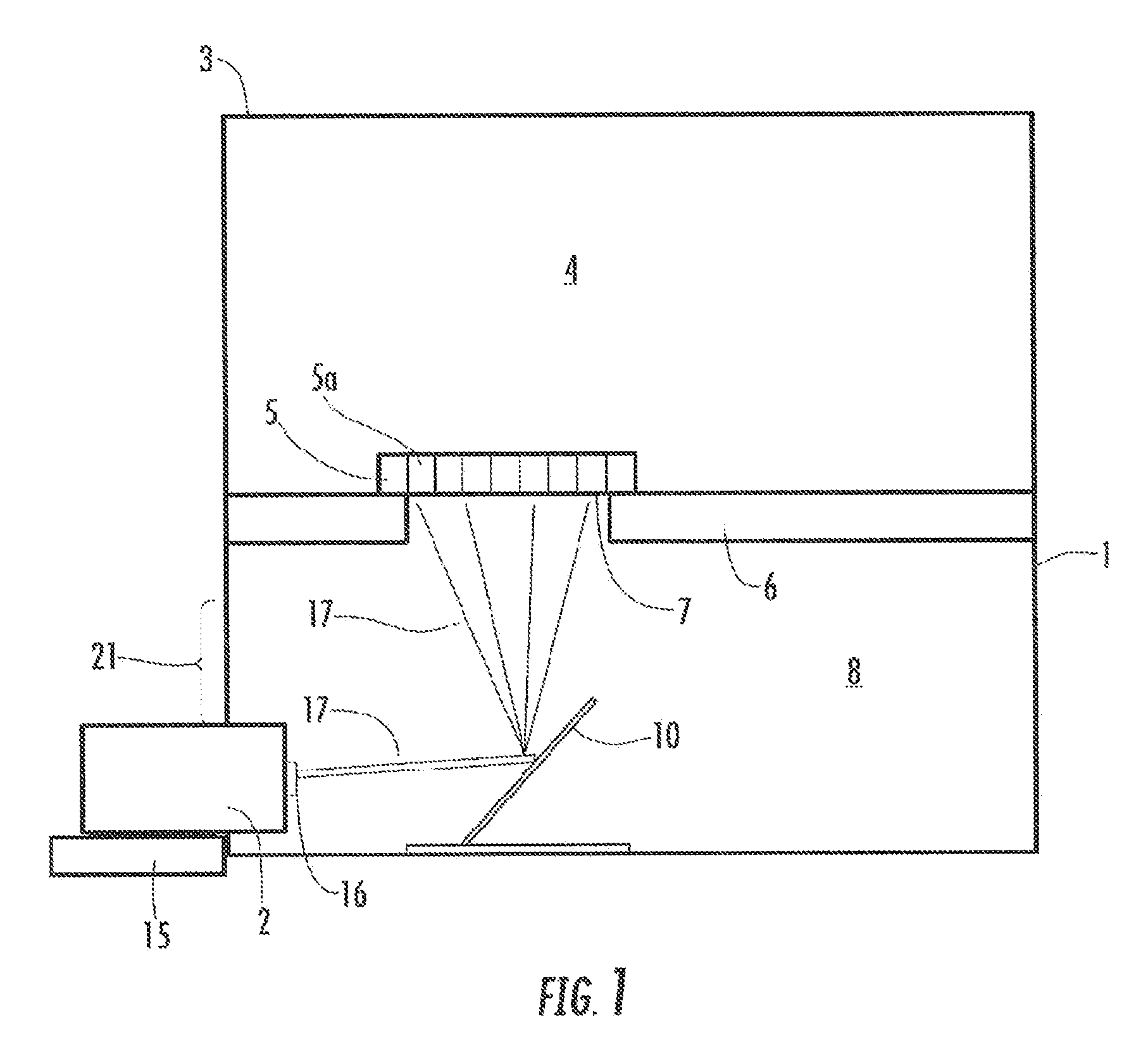

Method and system for replacing the water cooled laser in a microplate reader

ActiveUS8448322B2Prolong lifeEasy misalignmentRadiation pyrometryPolarisation spectroscopyWater coolingArgon laser light

The present invention relates to a method and system for repairing and refurbishing a microplate reader of the Flipr type which has a water cooled argon laser light source. The old laser is removed and replaced with a high power (300 to 500 mW) air cooled solid state laser as a replacement place on its own support and focused and wired to replace the old laser. The new product operates at lower power consumption yet provides accurate measurements.

Owner:LEEN THOMAS

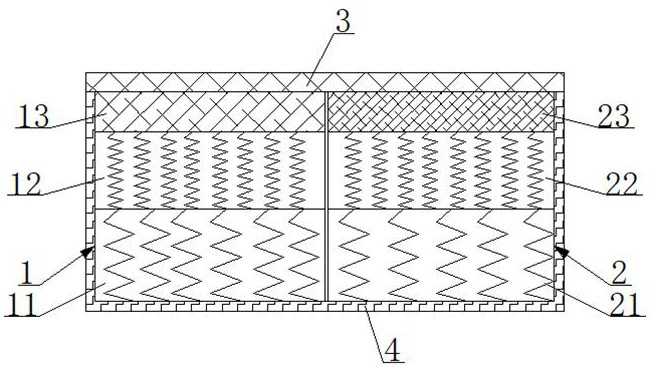

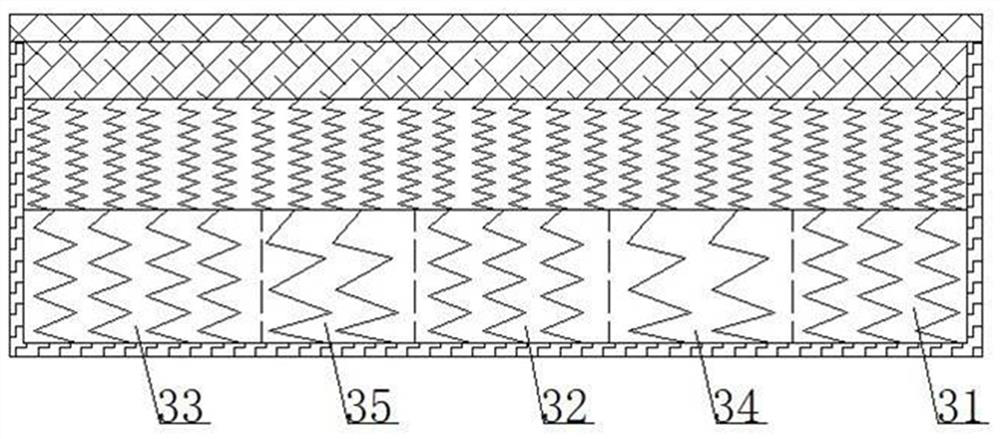

Mattress with left and right partitions and adjustable hardness and preparation method thereof

InactiveCN112006471AHardness: SoftImprove comfortStuffed mattressesSpring mattressesLeft halfMechanical engineering

The invention provides a mattress with left and right partitions and adjustable hardness and a preparation method of the mattress. The hardness of a left half part and the hardness of a right half part of the mattress are different. The mattress comprises a hard mattress body and a soft mattress body which are spliced left and right, the hardness of the hard mattress body is higher than that of the soft mattress body, the outer side of the mattress is sleeved with a cloth cover, and the upper side face of the cloth cover is a cotton cushion covering the hard mattress body and the soft mattressbody. The mattress is divided into the left area and the right area, the requirements of people with different weights and different body types for the hardness and the supporting performance of themattress are met, and the comfort of the mattress is improved by means of the air permeability and the moisture dissipation performance of the blasting cotton.

Owner:江苏金太阳家用纺织品有限公司

Method and system for replacing the water cooled laser in a microplate reader

ActiveUS8347478B2Prolong lifeEasy misalignmentMaterial analysis by optical meansEngineeringLaser light

The present invention relates to a method of refurbishing a microplate reader such as a FLIPR type microplate reader by the replacement of the water cooled laser with an LED source which provides a relatively homogeneous light and operating performance comparable to the laser light source.

Owner:LEEN THOMAS

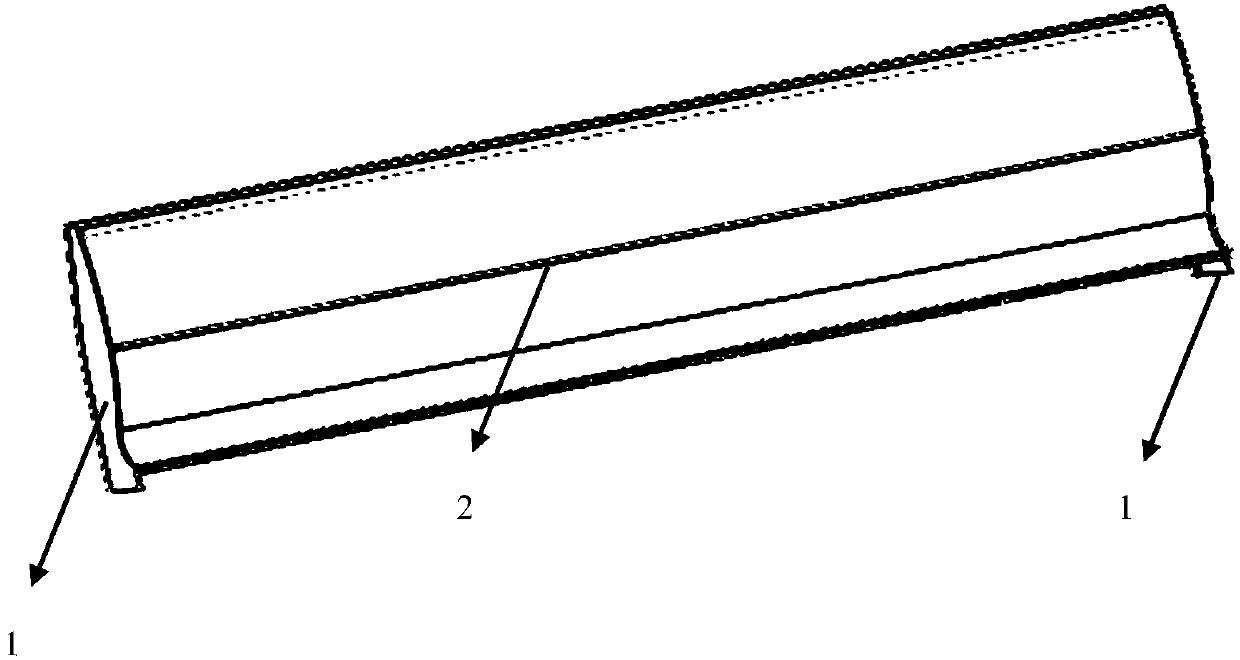

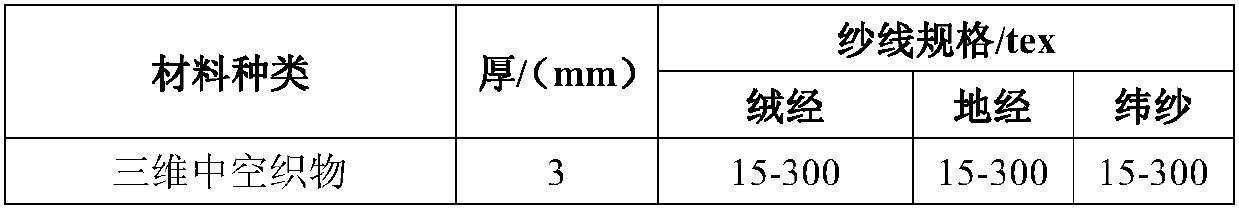

Preparation method of lightweight hollow woven fabric type composite material seat backrest

ActiveCN107856370AImprove mechanical propertiesEasy misalignmentGlass/slag layered productsSeatsFiberEngineering

The invention discloses a preparation method of a lightweight hollow woven fabric type composite material seat backrest. The seat backrest comprises two supporting plates, and a supporting surface which is arranged between the two supporting plates, wherein the two supporting plates are manufactured through fiber preforms; the supporting surface is manufactured through three-dimensional hollow woven fabrics. According to the method, the fiber preforms are used as the supporting plates, so that the problem of easy deviating of the conventional paving layers can be solved, and the mechanical property of the seat backrest is obviously improved; moreover, the preform paving and vacuum flow guiding integrated forming technology is performed, thus quick forming is achieved, and the problems suchas weak interface is avoided; the requirement on lightweight railcars in future can be met; in addition, the mechanical property of the seat backrest can be further improved.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Method and system for replacing the water cooled laser in a microplate reader

ActiveUS20100319177A1Prolong lifeEasy misalignmentRadiation pyrometryPolarisation spectroscopyWater coolingSolid-state laser

The present invention relates to a method and system for repairing and refurbishing a microplate reader of the Flipr type which has a water cooled argon laser light source. The old laser is removed and replaced with a high power (300 to 500 mW) air cooled solid state laser as a replacement place on its own support and focused and wired to replace the old laser. The new product operates at lower power consumption yet provides accurate measurements.

Owner:LEEN THOMAS

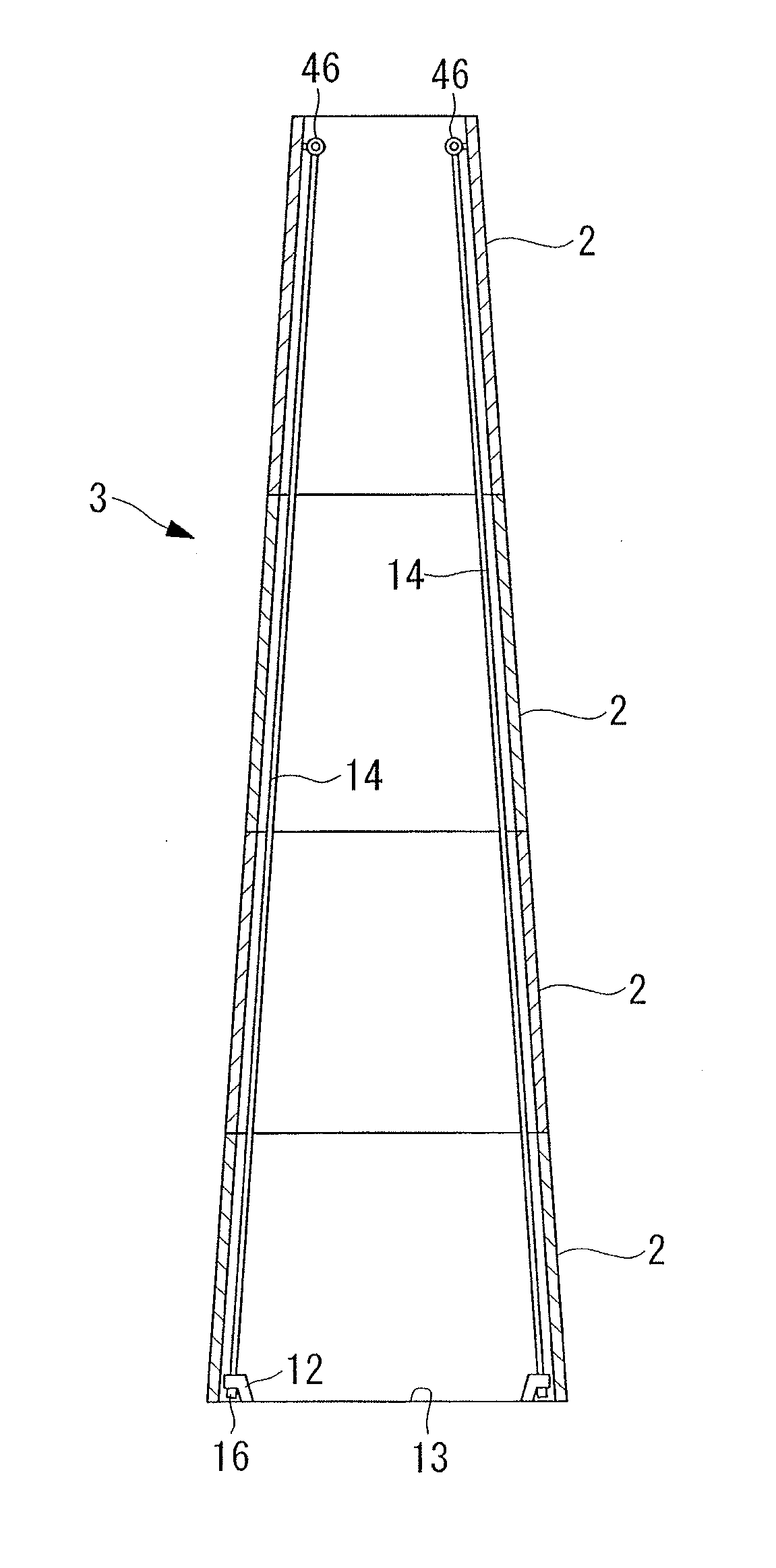

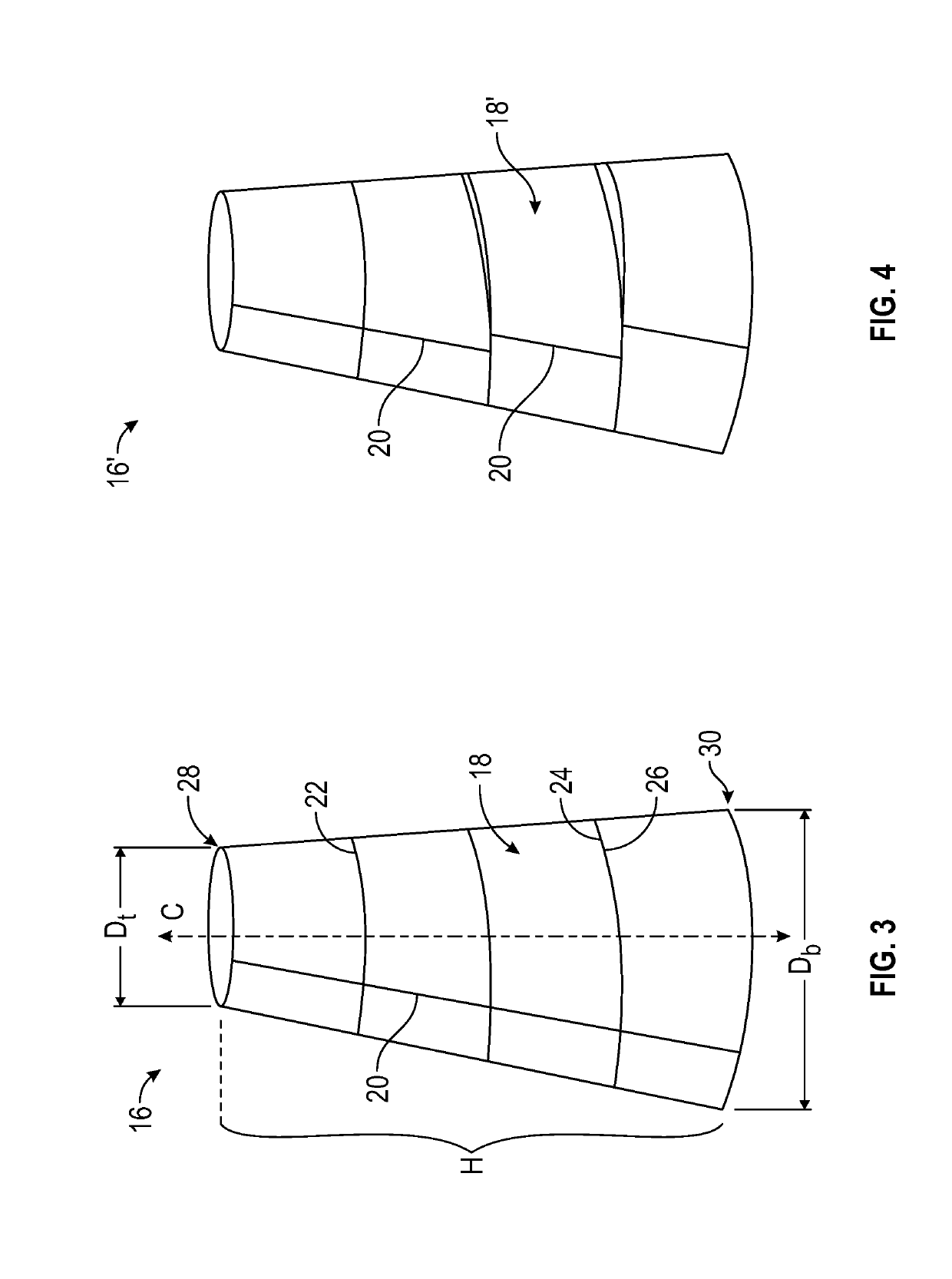

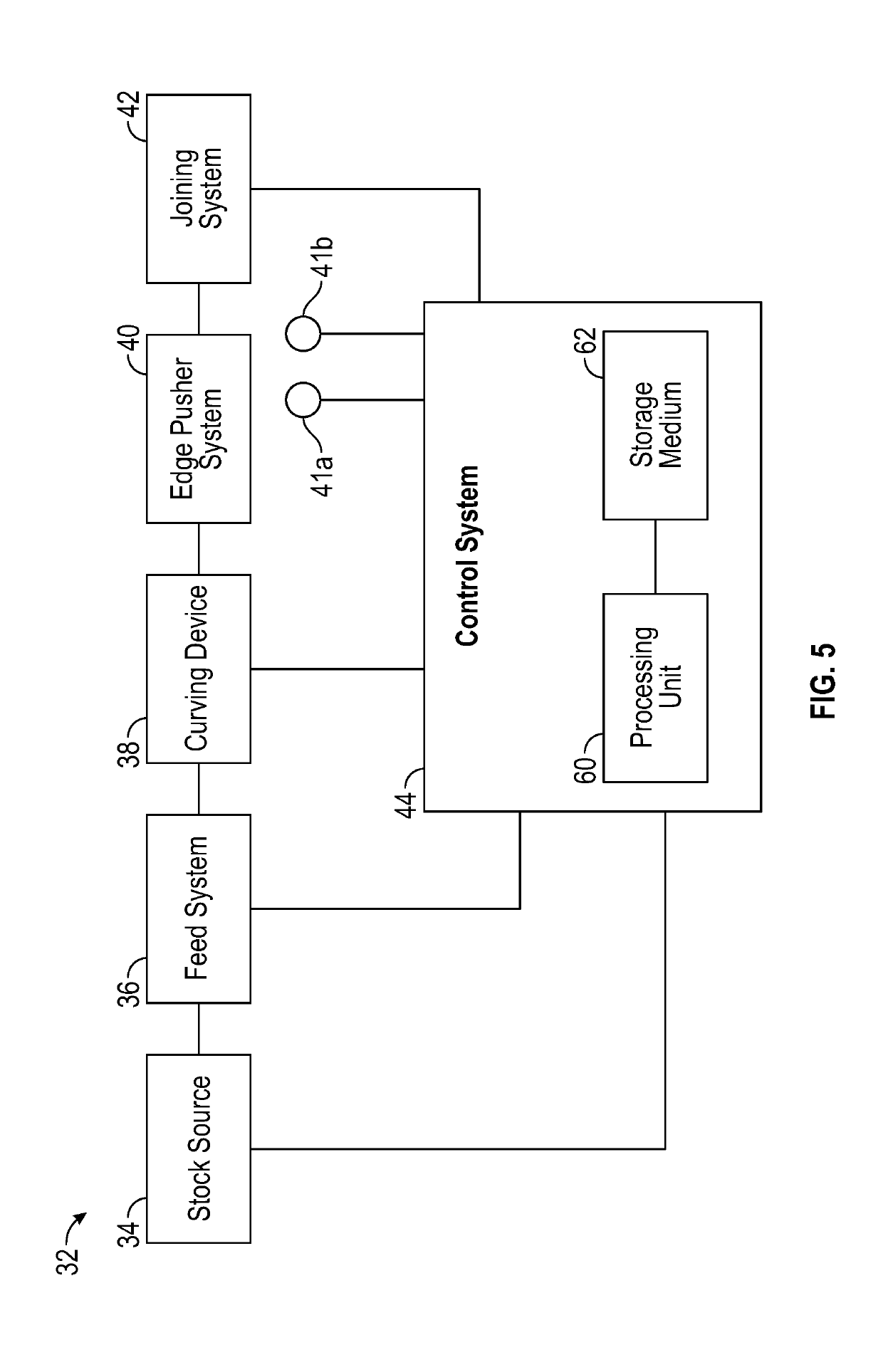

Spiral forming

ActiveUS20190160505A1Easy to controlReduce biasWind motor supports/mountsMeasuring devicesEngineeringMechanical engineering

Spiral forming methods can be used to join edges of a rolled material along a spiral joint to form conical and / or cylindrical structures. Alignment of the edges of the rolled material can be controlled in a wrapping direction as the material is being joined along the spiral joint to form the structure. By controlling alignment of the edges of the material as the edges of the material are being joined, small corrections can be made over the course of forming the structure facilitating control over geometric tolerances of the resulting spiral formed structure.

Owner:KEYSTONE TOWER SYST

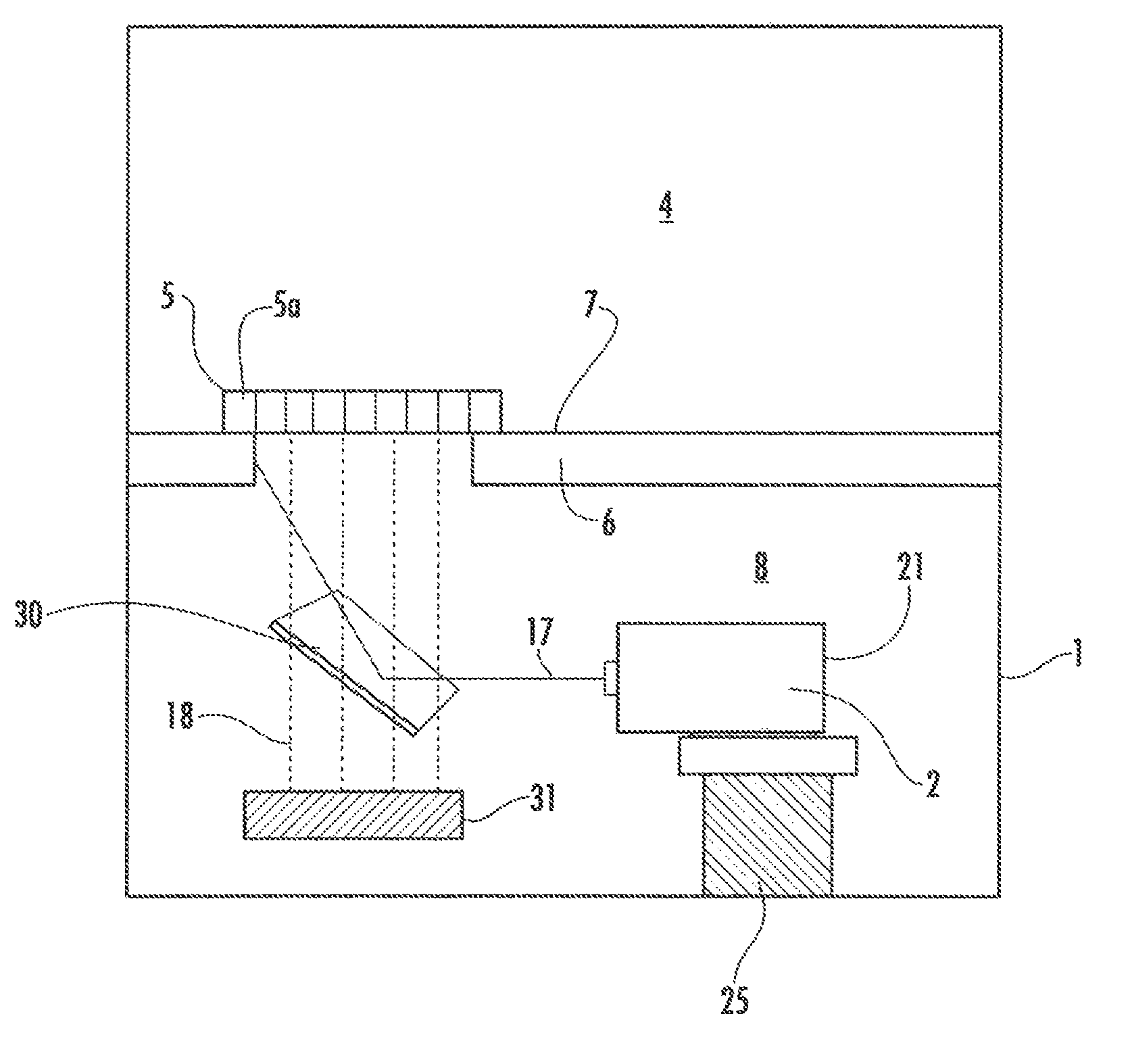

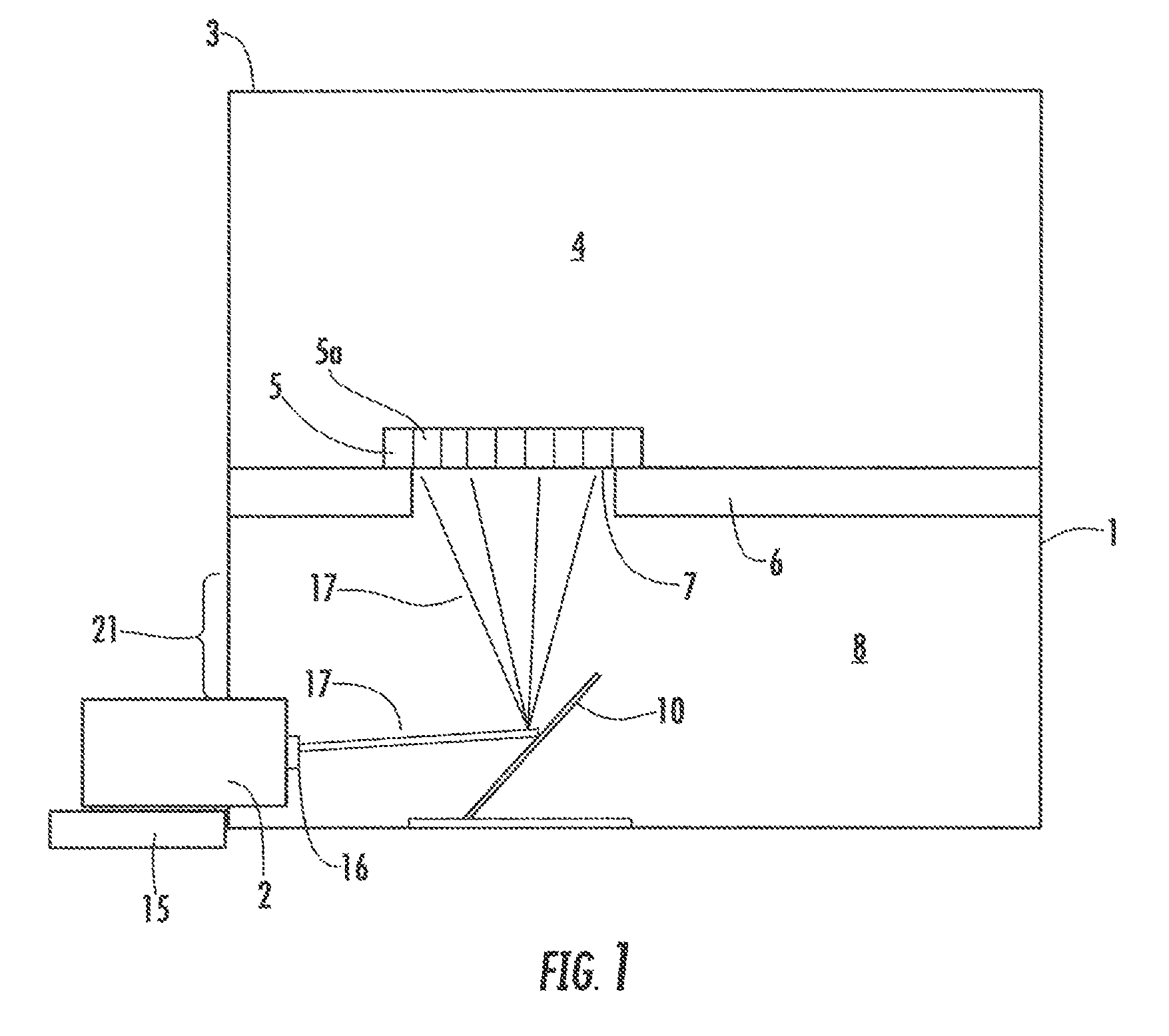

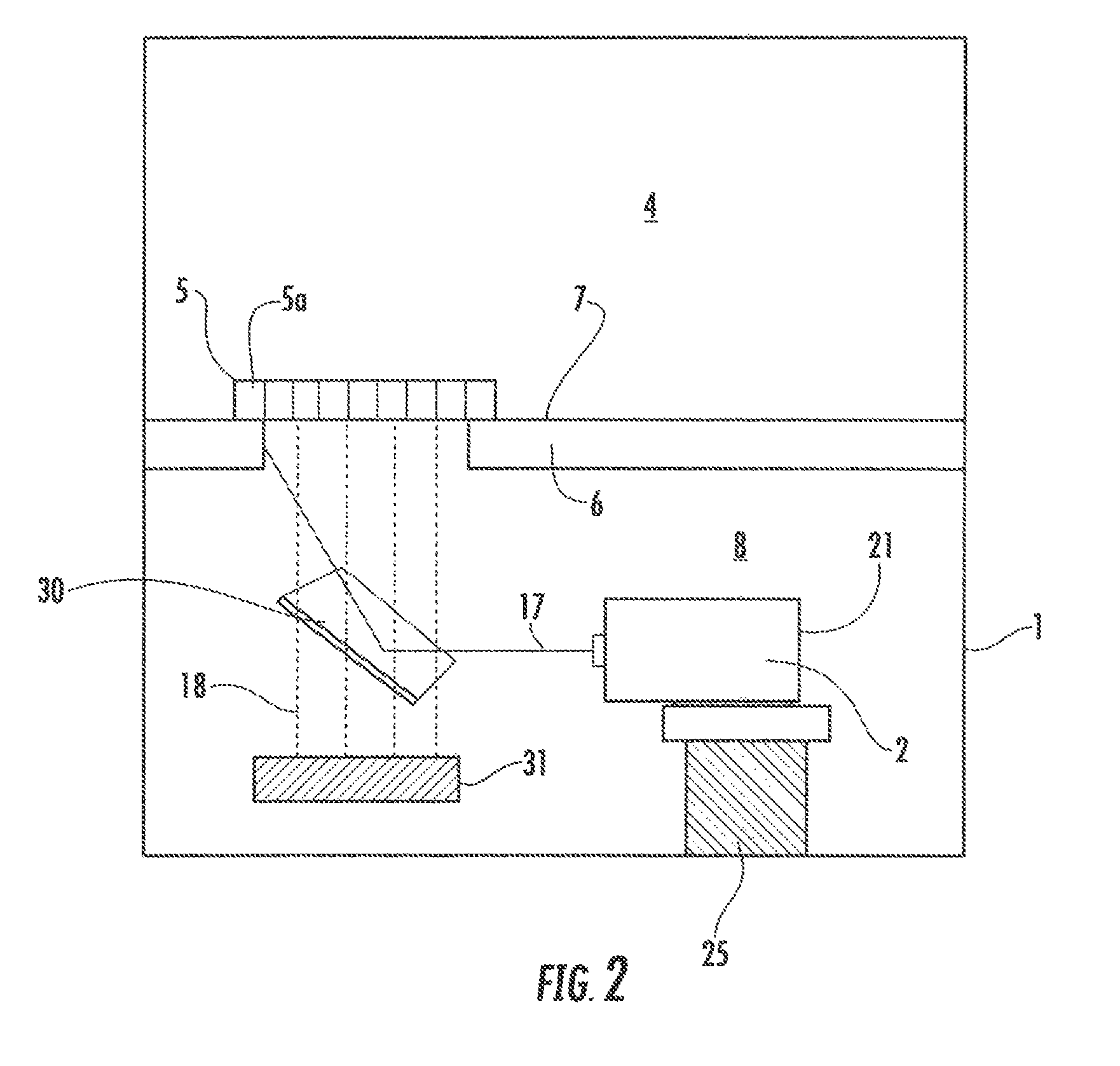

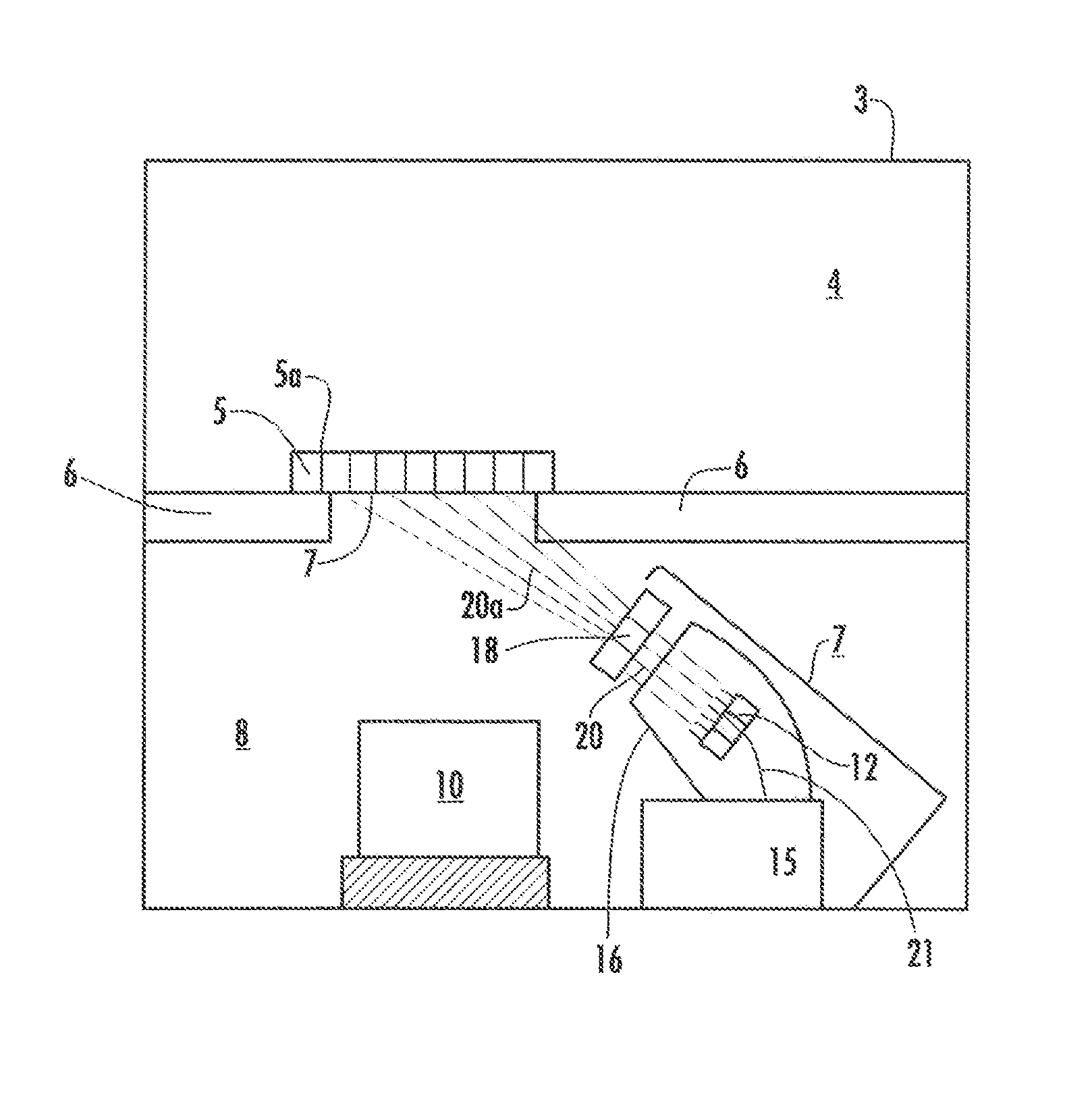

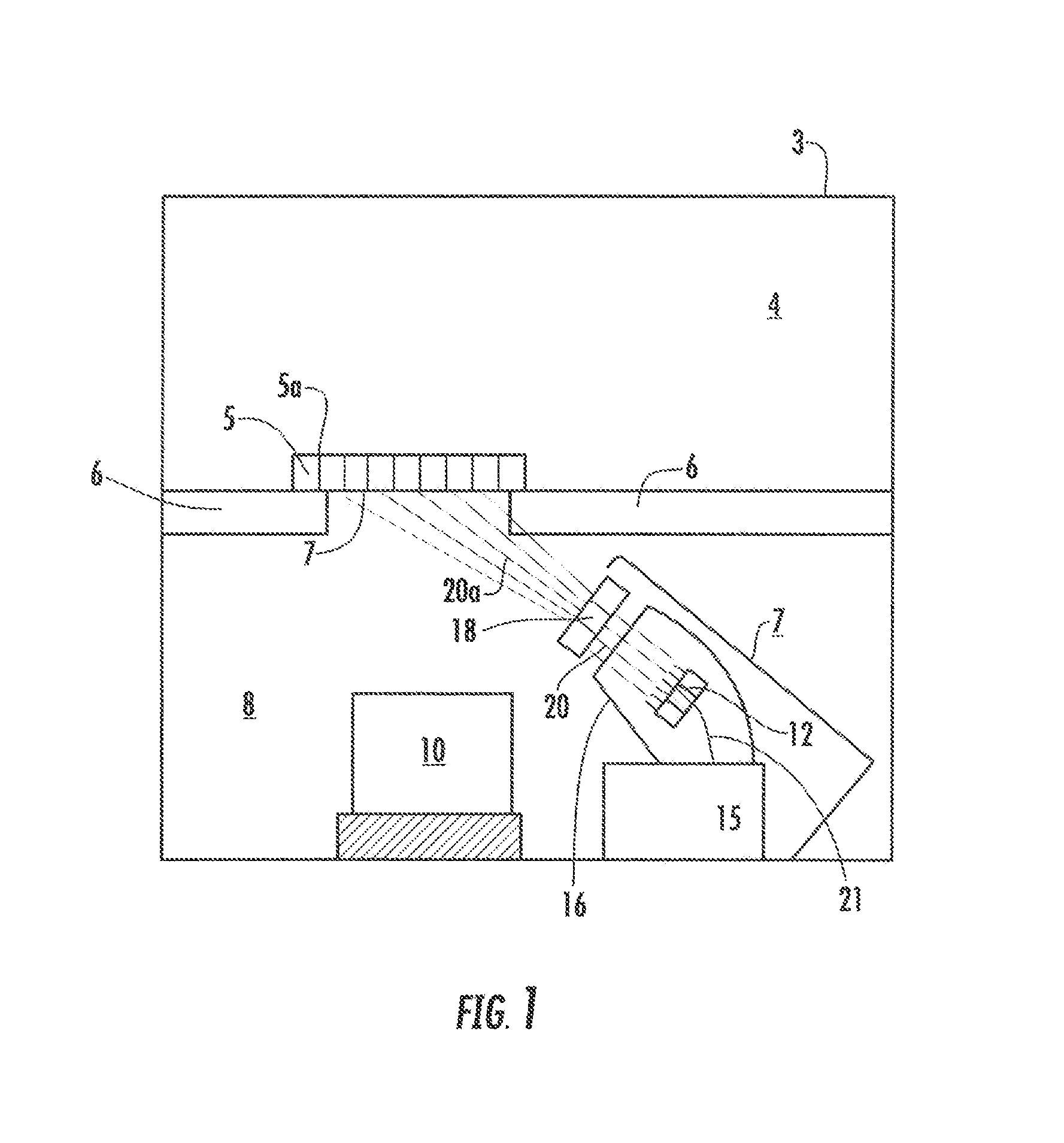

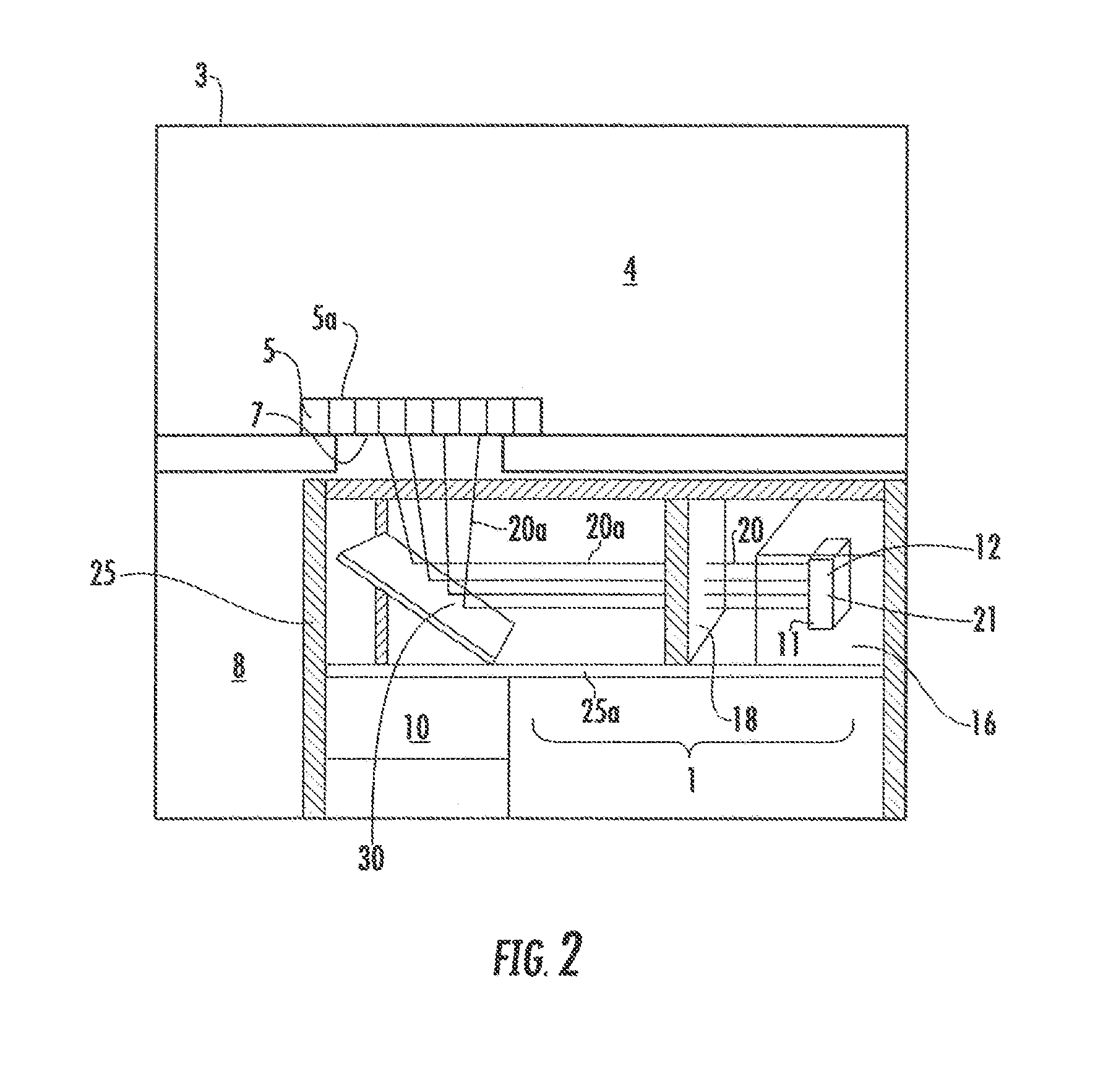

Laser irradiation apparatus and method for manufacturing semiconductor device

InactiveUS7374985B2Shorten the timeReadjust the optical system more easily and more accuratelyLaser detailsSolid-state devicesLight beamIrradiation

The linear laser beam generally has a width of 1 mm or less, and it is necessary to adjust the optical system with high accuracy in order to form the laser beam having such a narrow width and having a homogeneous intensity distribution. The adjustment of the optical system requires a large amount of time, and the laser irradiation apparatus using this optical system cannot be used during the adjustment of the optical system. This causes the throughput to decrease. The present invention is made to facilitate a readjustment of the optical system and to shorten the time required for it. When the misalignment of the laser beam is corrected to keep the incident position in the optical system the same by moving the laser beam parallel with the use of a single optical element, it is no longer necessary to readjust all the optical elements, and therefore the time can be saved.

Owner:SEMICON ENERGY LAB CO LTD

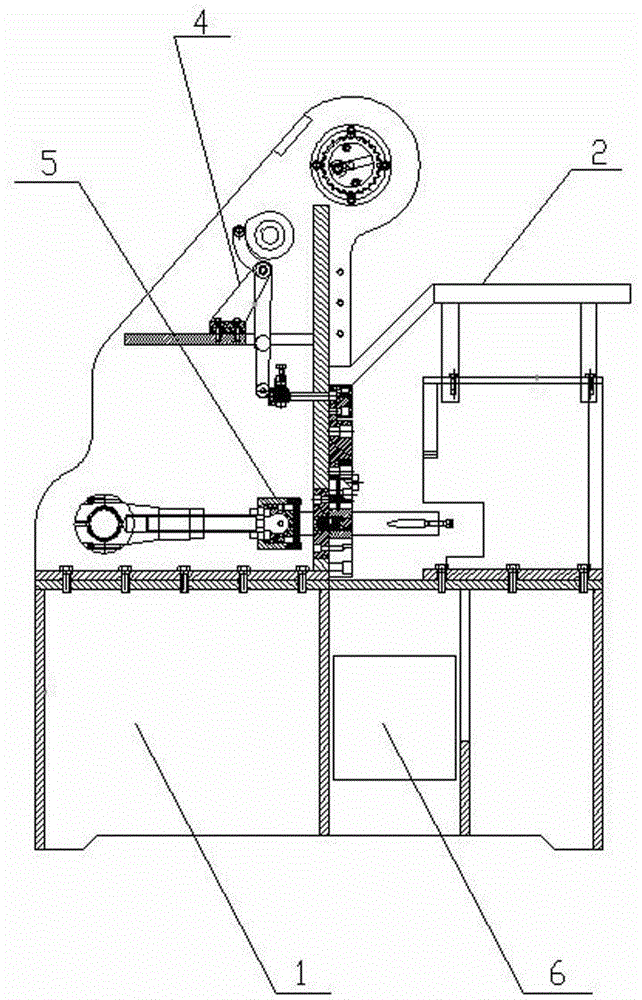

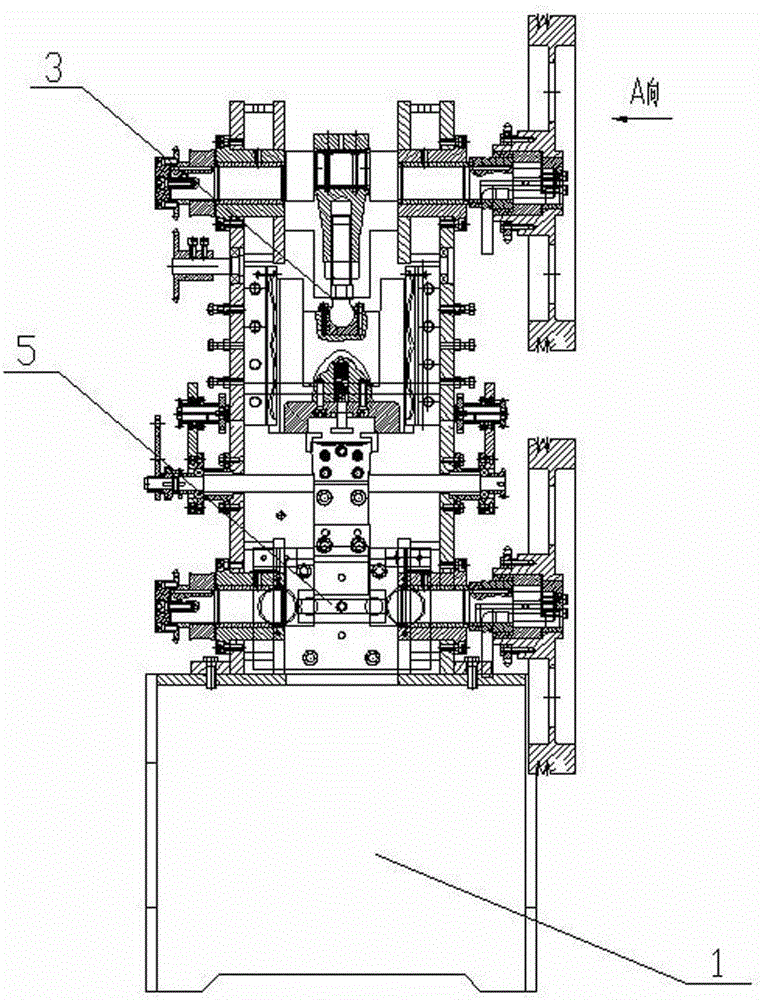

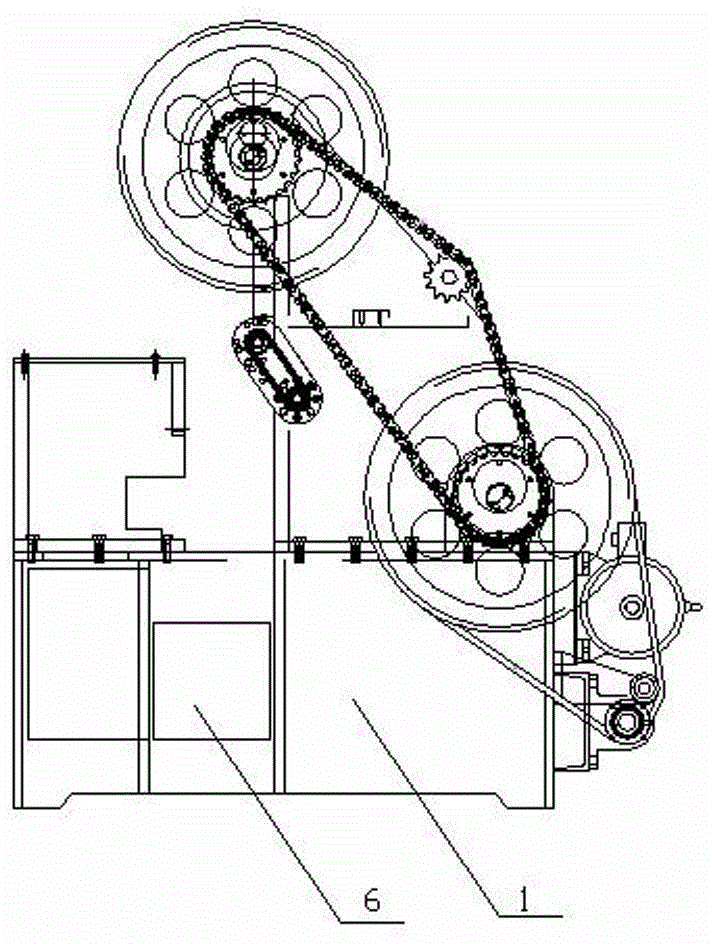

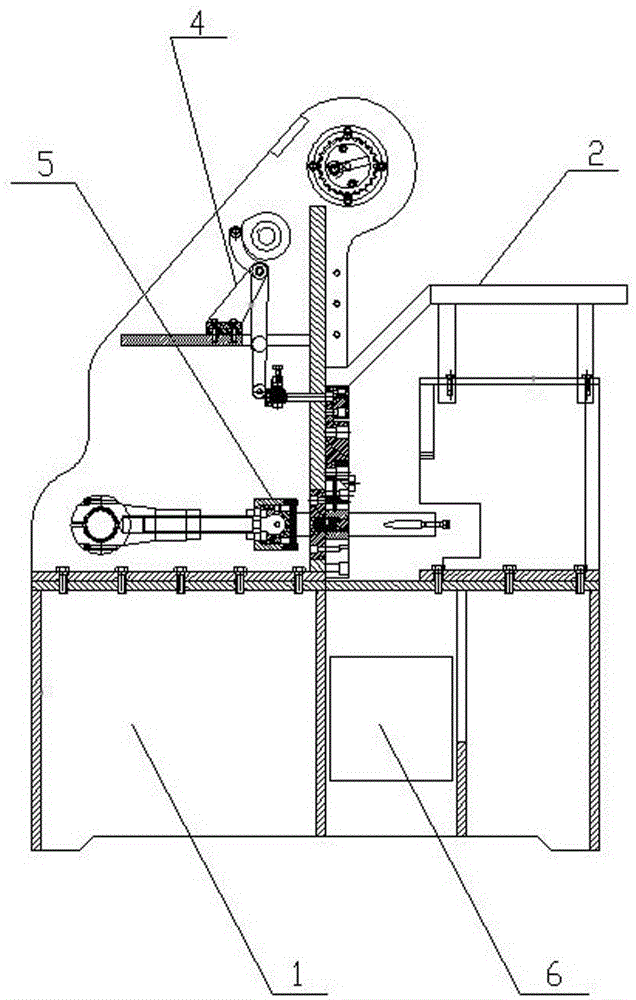

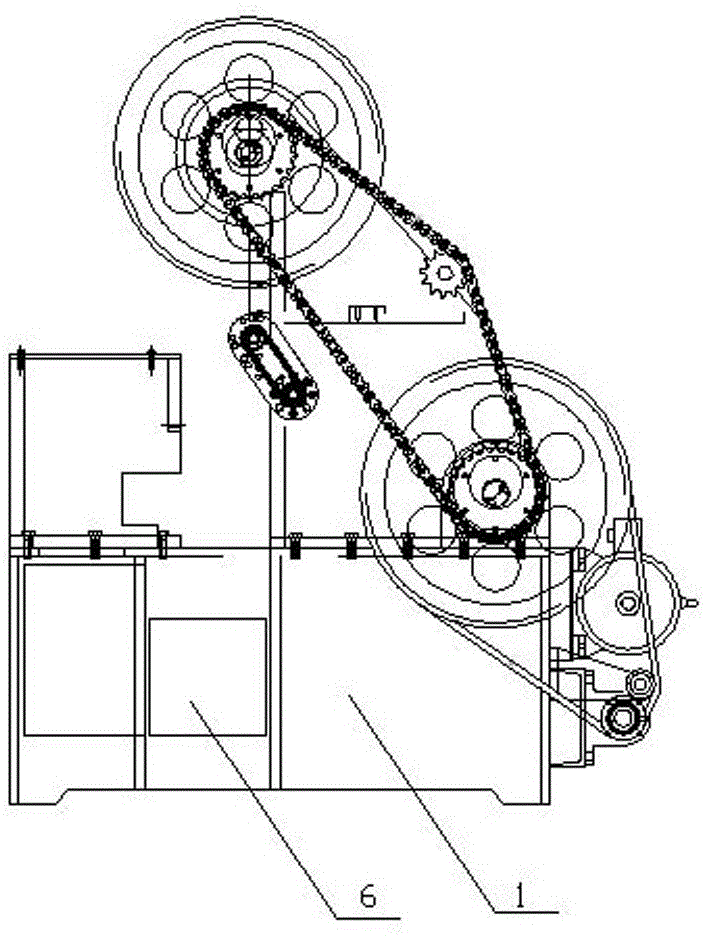

Automatic forming machine for double-hook hoops

An automatic forming machine for double-hook hoops comprises a machine frame, a drive device arranged on the machine frame, a feeding device, a bending device, a material pushing device and a hook device, wherein the feeding device, the bending device, the material pushing device and the hook device are arranged on the machine frame and driven by the drive device. A receiving box is arranged below the hook device on the machine frame, the tail end of the feeding device is in butt joint with a station groove of the bending device, a long-strip-shaped steel bar which is conveyed into the station groove from the feeding device is punched downwards by the bending device to form a U-shaped structure, the steel bar of the U-shaped structure is then pushed by the material pushing device into a station groove of the hook device from the station groove of the bending device, and after the two ends of the steel bar of the U-shaped structure are bent to form hooked structures through the hook device, the steel bar automatically falls into the receiving box, so that automatic double-hook hooping work for the steel bar is completed. According to the automatic forming machine for the double-hook hoops, punching shearing force can be used for completing multiple machining processes from the long-strip-shaped steel bar to the final hook product at a time, the processes are simple, the automation degree is high, and the hook effect is good. Production efficiency is improved.

Owner:RUZHOU ZHENGTIE SANJIA CEMENT PROD

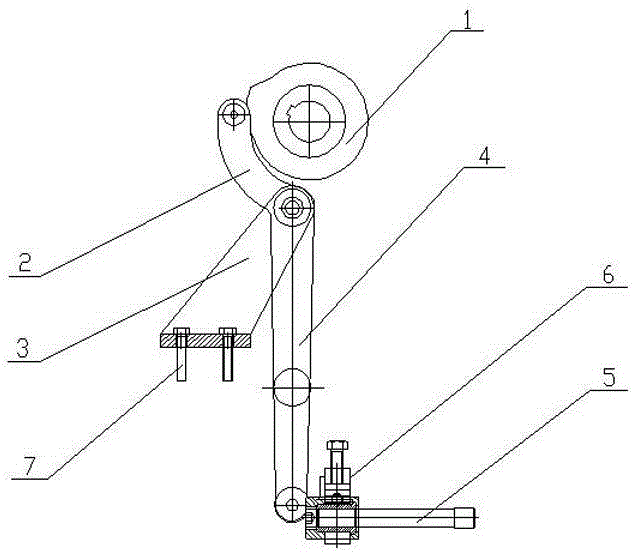

Material pushing device for double-hook hooping machine

A material pushing device for a double-hook hooping machine is provided with a cam driven by a drive device, a cam pushing sleeve is arranged on the cam and located on the moving track of the cam, one end of the cam pushing sleeve is fixedly hinged to a cam pushing sleeve fixing piece, a connecting rod is further fixedly connected to the end, hinged to the cam pushing sleeve fixing piece, of the cam pushing sleeve, a material pushing rod used for pushing materials is horizontally arranged at the bottom end of the connecting rod, the material pushing rod is sleeved with a guiding shaft support used for limiting vertical movement of the material pushing rod, and the cam pushing sleeve can periodically drive the connecting rod to move back and forth with the hinging portion of the cam pushing sleeve and the cam pushing sleeve fixing piece as a pivot in the circumferential moving process of the cam, so that the material pushing rod is driven to horizontally move so as to push materials. The material pushing device is simple in structure and high in automation degree, saves labor, greatly lowers potential safety hazards of the material pushing motion, improves operation safety and reliability, and is good in practical effect.

Owner:RUZHOU ZHENGTIE SANJIA CEMENT PROD

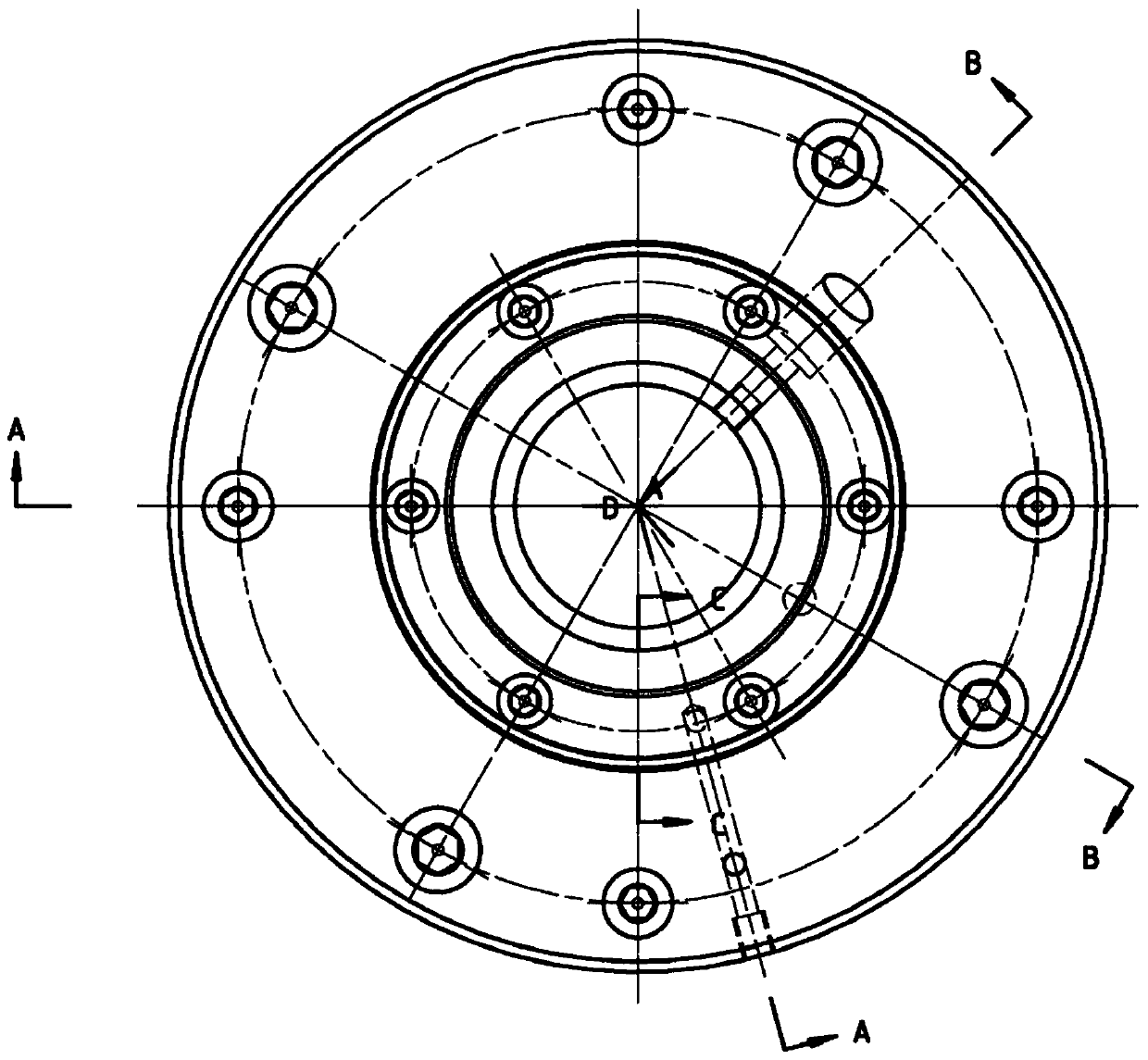

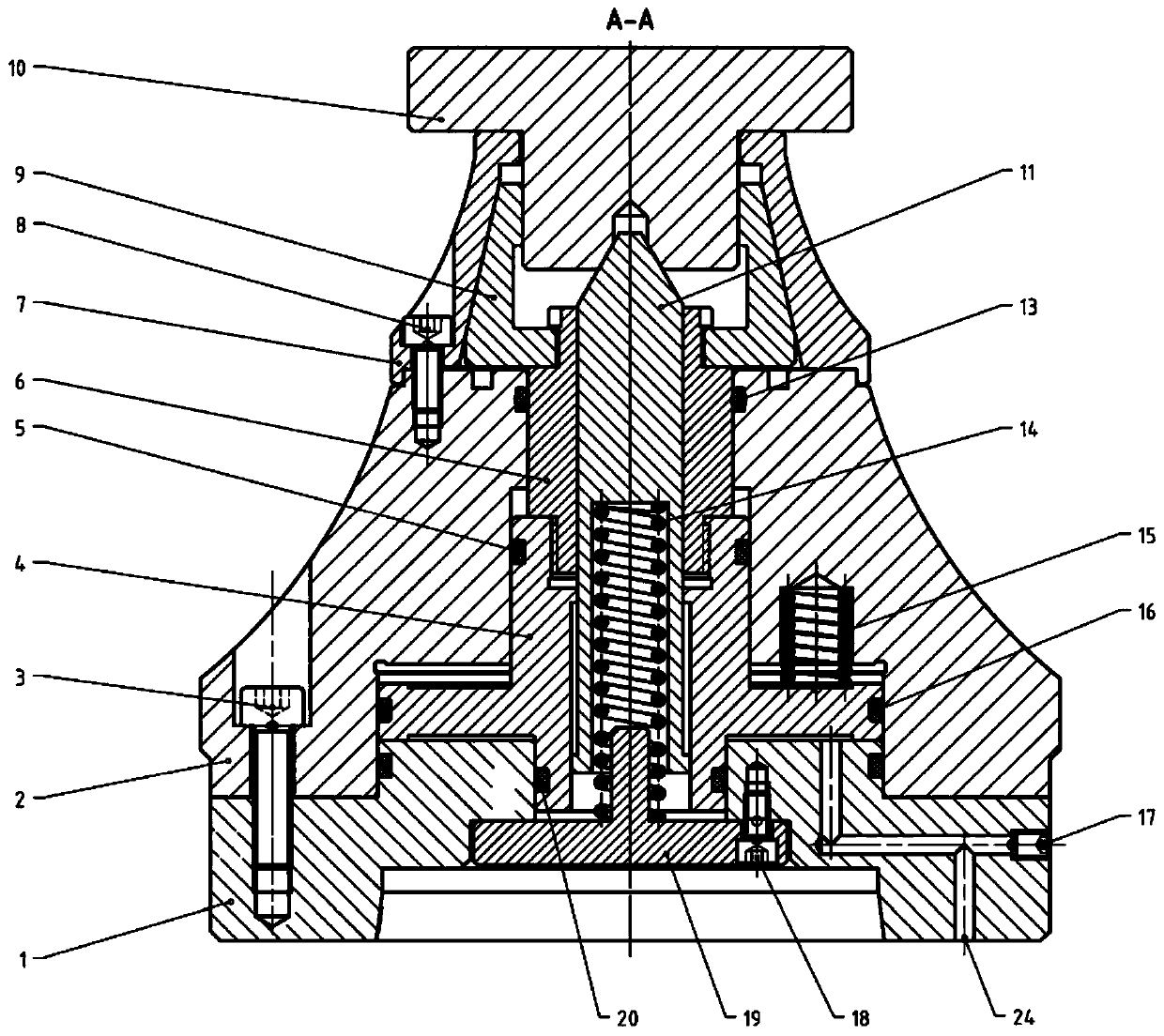

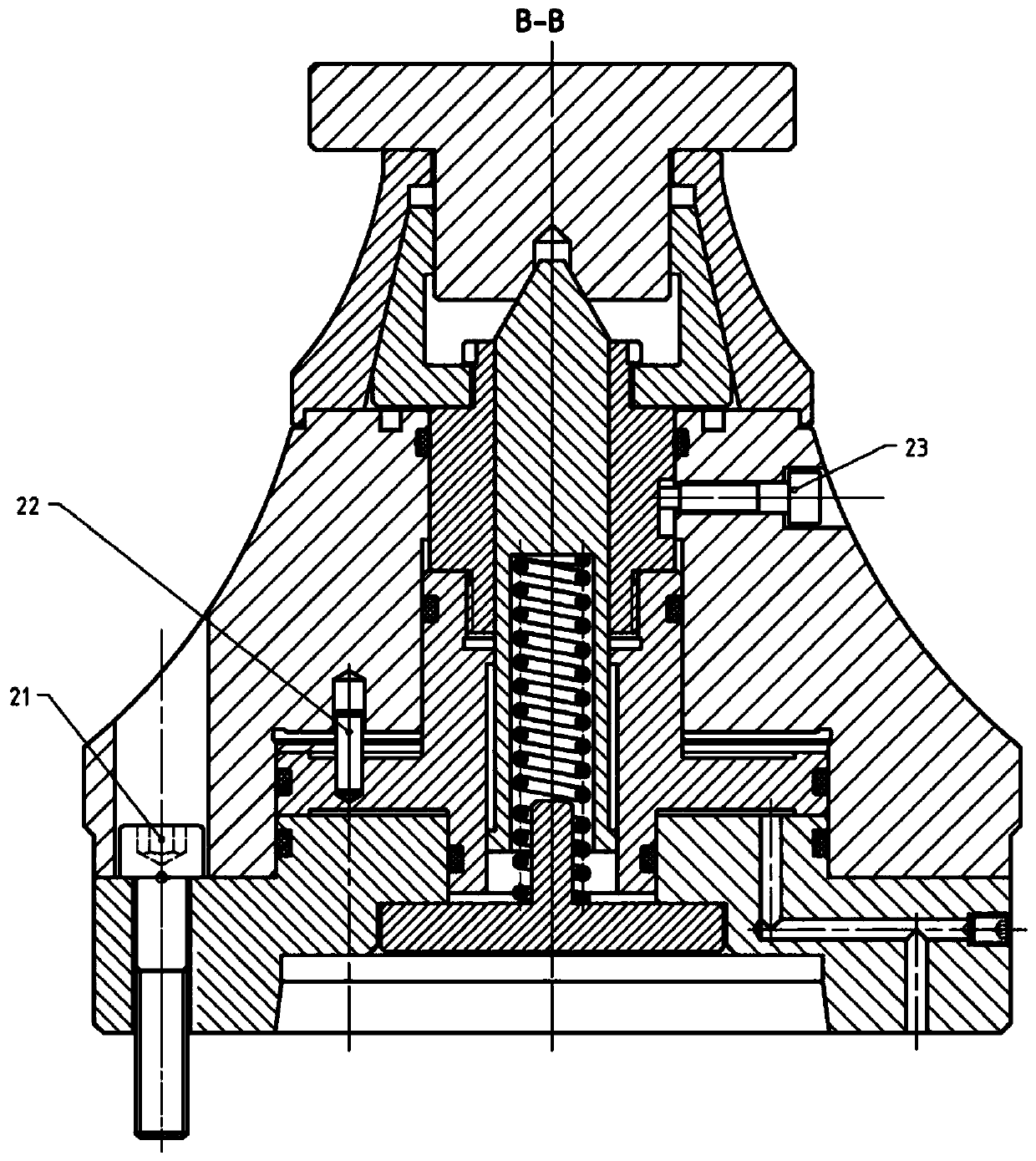

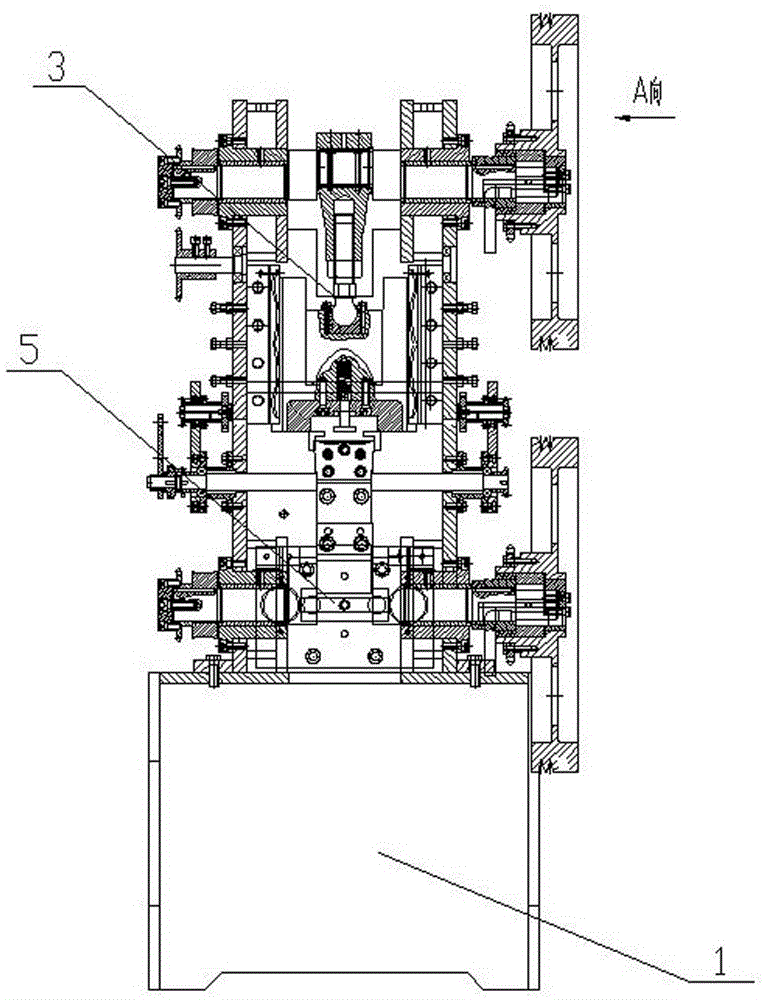

A gear grinding jig for high-precision quick-change shafts

ActiveCN106808031BGuaranteed positioningPrecise positioningGear-cutting machinesGear teethGear grindingEngineering

The invention discloses a high-precision gear grinding clamp for quickly changing shafts. The high-precision gear grinding clamp comprises a connection flange connected to a machine tool, a piston is arranged on the upper side of the connection flange, the upper side of the piston is connected with a pull rod, and the upper side of the pull rod is connected with an expanding sleeve. A tip for centering a workpiece is arranged in the internal space of the piston and the internal space of the pull rod, a blind hole is formed in the bottom of the tip, a tip spring is arranged in the blind hole, an end cover is arranged on the bottom of the tip spring, and the end cover and the connection flange are fixed. A base is arranged on the outer side of the piston and the outer side of the pull rod in a sleeving manner, the base and the connection flange are fixed, a supporting base is arranged on the outer side of the expanding sleeve in a sleeving manner, the supporting base and the base are fixed, and a flange oil path connected to a gap between the piston and the connection flange is arranged on the connection flange. The high-precision gear grinding clamp can achieve quick product changing, the high-precision gear grinding clamp is provided with the center guiding movable tip which is beneficial to mechanical arm feeding and discharging, the product changing efficiency is improved while the clamping precision is guaranteed, the foreign technological monopoly is broken, and the clamp cost is reduced.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

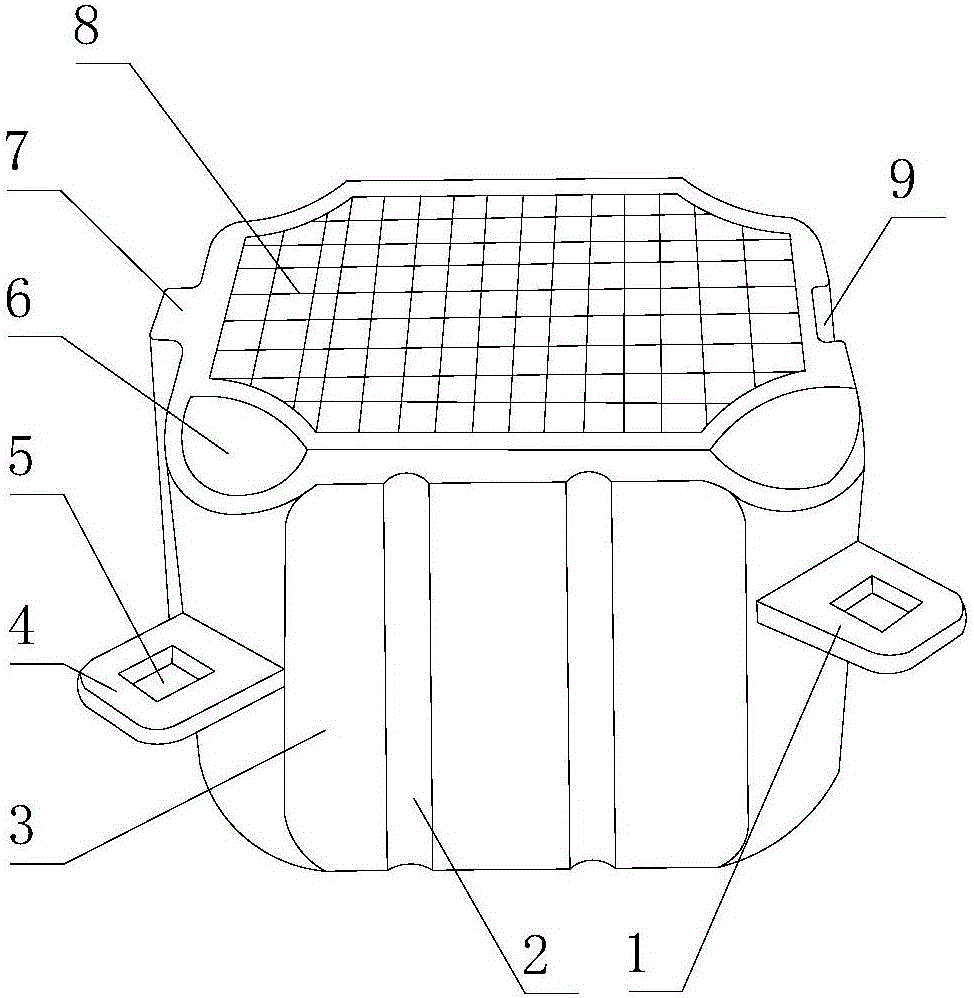

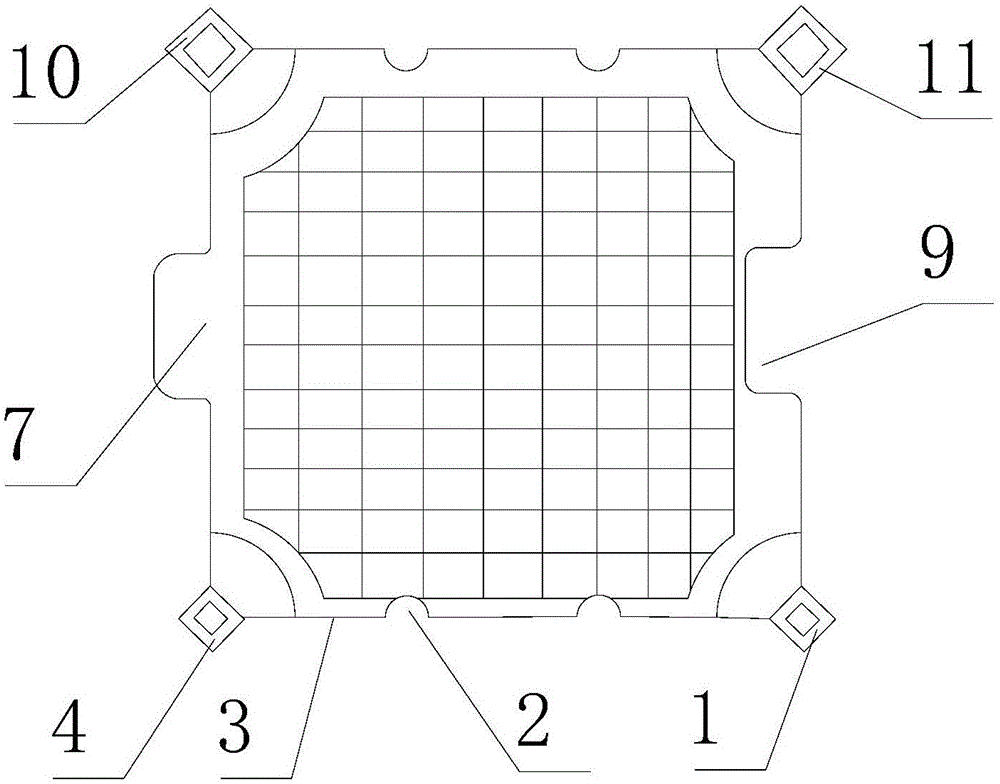

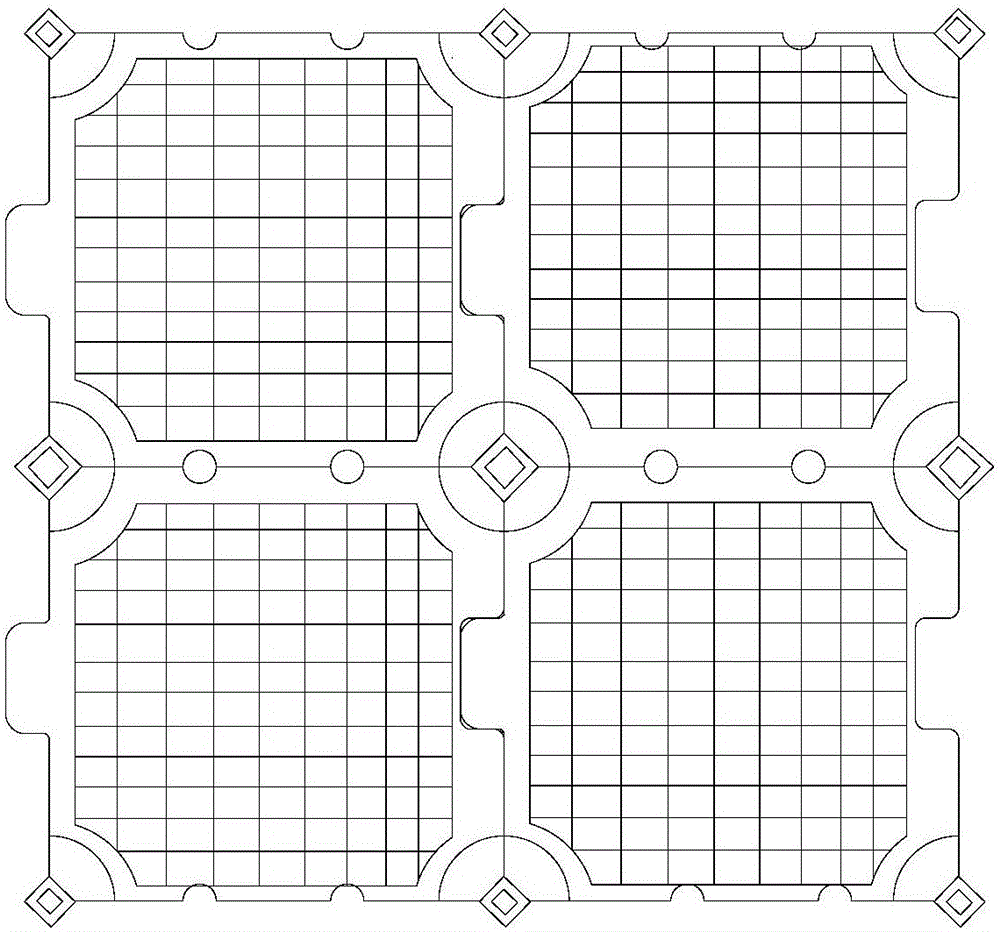

Buoyancy tank for building water wharf

InactiveCN105951665AEasy misalignmentPlay a stabilizing roleBreakwatersQuaysSurface waterBuoyancy function

The invention relates to a buoyancy tank for building water wharf. The buoyancy tank comprises a tank body; the internal of the tank body is hollowed; the tank body is cubic, and is provided with four sets of connecting lugs; antiskid patterns are arranged on the top surface of the tank body; convex blocks and grooves are respectively arranged on two opposite side surfaces of the tank body; the convex blocks are matched with the adjacent grooves of the tank body; and drain grooves are formed in the other two side surfaces of the tank body. The buoyancy tank is provided with the drain grooves and the convex blocks and the grooves for preventing staggering, so that a stabilizing effect is achieved, and the problems of surface water accumulation slippage of a water wharf and easy staggering between buoyancy tanks are solved.

Owner:陈桂霞

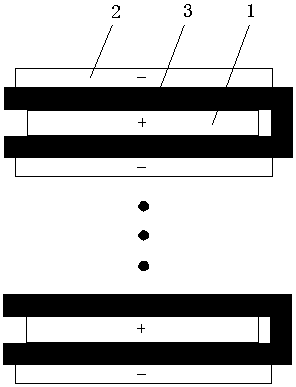

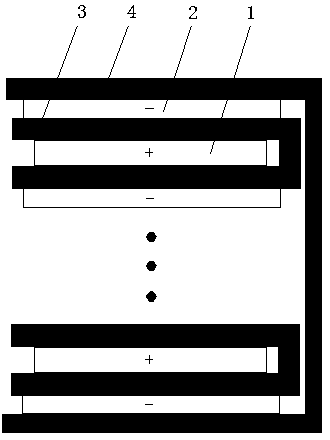

Lithium-ion battery and manufacturing method

PendingCN111477945AEasy misalignmentSolve the problem of easy misalignmentFinal product manufactureElectrolyte accumulators manufacturePhysical chemistryEngineering

The invention relates to a lithium ion battery and a manufacturing method. The lithium ion battery comprises a negative plate, a U-shaped diaphragm plate and a positive plate; and the positive plate is wrapped by a U-shaped diaphragm plate, the U-shaped diaphragm plate and the positive plate wrapped by the U-shaped diaphragm plate are a half-electrode unit formed by hot-pressing composite processtreatment, the negative plate and the half-electrode units are sequentially stacked to form a basic electrode unit, the basic electrode units are stacked and coated by a diaphragm to form a multi-element electrode unit, the multi-element electrode unit at least comprises two basic electrode units, and the multi-element electrode unit forms a battery monomer. The lithium ion battery has the advantages of being high in assembly efficiency and not prone to dislocation.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

Mortise lock for adjustable explosion-proof cover

ActiveCN104420713BPrecisely adjust the relative distanceImprove working conditionBuilding locksEngineeringScrew joint

Disclosed is a mortise door lock of an adjustable explosion-proof cover. The mortise door lock of an adjustable explosion-proof cover comprises a lock cylinder arranged in a door sheet, a front face plate, a rear face plate and a handle, wherein the front face plate, the rear face plate and the handle are arranged outside the door sheet. The mortise door lock is characterized in that the lock cylinder is arranged in a lock hole in the door sheet; the outer end of the lock cylinder is sequentially covered with the explosion-proof cover and a protective cover; the protective cover is in screwed joint with a fixed plate arranged on the inner side of the door sheet to enable the door sheet to be clamped between the protective cover and the fixed plate; and a bolt height adjusting device capable of adjusting the opposite distance between the explosion-proof cover and the lock cylinder is arranged between the explosion-proof cover and the fixed plate or between the explosion-proof cover and the protective cover. The mortise door lock has the beneficial effects that the bolt adjusting device is utilized so that the opposite distance between the explosion-proof cover and the lock cylinder can be precisely adjusted, and the advantages of being convenient to adjust, large in size adjusting range and the like are achieved; the protective cover is arranged outside the explosion-proof cover, the lock cylinder and the explosion-proof cover are covered with the protective cover, and meanwhile the bottom of the explosion-proof cover is tightly combined with the door sheet; and the side wall of the explosion-proof cover is a slope, and the phenomenon that a burglar damages the protective cover in prying or clamping and other manners can be effectively avoided.

Owner:GUANGDONG JUSEN HARDWARE PRECISION MFG CO LTD

A double hook stirrup automatic forming machine

An automatic forming machine for double-hook hoops comprises a machine frame, a drive device arranged on the machine frame, a feeding device, a bending device, a material pushing device and a hook device, wherein the feeding device, the bending device, the material pushing device and the hook device are arranged on the machine frame and driven by the drive device. A receiving box is arranged below the hook device on the machine frame, the tail end of the feeding device is in butt joint with a station groove of the bending device, a long-strip-shaped steel bar which is conveyed into the station groove from the feeding device is punched downwards by the bending device to form a U-shaped structure, the steel bar of the U-shaped structure is then pushed by the material pushing device into a station groove of the hook device from the station groove of the bending device, and after the two ends of the steel bar of the U-shaped structure are bent to form hooked structures through the hook device, the steel bar automatically falls into the receiving box, so that automatic double-hook hooping work for the steel bar is completed. According to the automatic forming machine for the double-hook hoops, punching shearing force can be used for completing multiple machining processes from the long-strip-shaped steel bar to the final hook product at a time, the processes are simple, the automation degree is high, and the hook effect is good. Production efficiency is improved.

Owner:RUZHOU ZHENGTIE SANJIA CEMENT PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com