Lithium-ion battery and manufacturing method

A manufacturing method and technology of lithium-ion batteries, which are applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of low assembly efficiency, poor safety, and easy misalignment of electrodes, and achieve high assembly efficiency and difficult Misalignment, stable bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

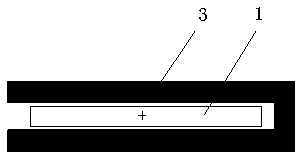

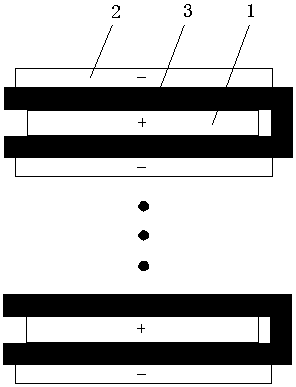

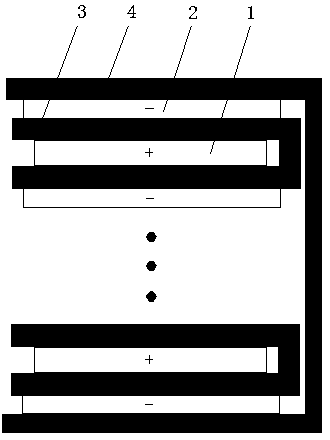

[0032] Such as Figure 1-7 As shown, a lithium-ion battery includes a negative plate 2, a U-shaped diaphragm plate 3, and a positive plate 1. The positive plate 1 is wrapped by a U-shaped diaphragm plate 3, and the U-shaped diaphragm plate 3 and its wrapped positive plate 1 is a half-electrode unit formed by hot-pressing composite process, such as figure 1 , the negative plate 2 and the half-electrode unit are stacked in sequence to form a basic electrode unit, such as figure 2 , the basic electrode units are stacked and covered by the separator 4 to form a multi-element electrode unit, such as image 3 , the multi-element electrode unit contains at least two basic electrode units, and the multi-element electrode unit forms a battery cell, such as Figure 4 .

[0033] The surface of the base film of the U-shaped diaphragm plate 3 is also coated with a coating layer that enhances the safety of the diaphragm. The safe material components are at least one or more of Al2O3 and...

Embodiment 2

[0038] The manufacture method of lithium ion battery of the present invention, comprises the following steps:

[0039] Step 1): coating the surface of both sides of the U-shaped diaphragm plate with an adhesive coating substance, and bonding the positive plate and the U-shaped diaphragm plate;

[0040] Step 2): Apply temperature and pressure to the positive plate and U-shaped diaphragm plate while bonding, that is, hot pressing composite process, the temperature range is 50-150°C, and the applied pressure is 0-1000Kg / cm 2 , the time is 0-300s;

[0041] Step 3): the above steps form a half-electrode unit;

[0042] Step 4): Alternately stack the half-electrode units formed above and their corresponding electrodes of the opposite sex in turn, that is, the polarity of the electrode wrapped by the U-shaped diaphragm plate is opposite to that of the adjacent electrode on the outside. When the wrapped electrode unit is positive, the U-shaped diaphragm plate Both sides are negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com