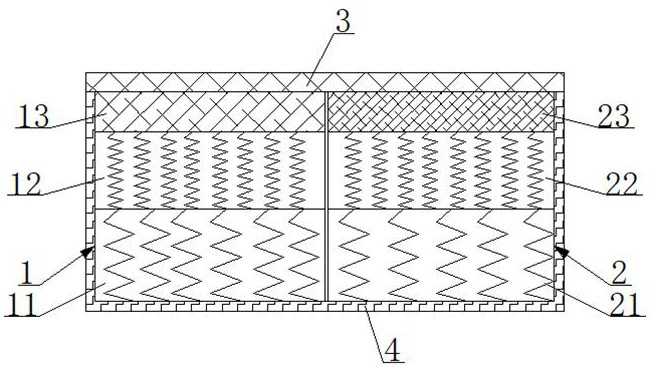

Mattress with left and right partitions and adjustable hardness and preparation method thereof

A soft mattress, mattress technology, applied in mattresses, spring mattresses, stuffed mattresses, etc., can solve the problems of customer loss, heavy spring mattresses, poor air permeability and hygroscopicity, etc. Comfort, effectiveness in solving traction problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a mattress with left and right partitions and adjustable hardness and softness, which includes the following steps:

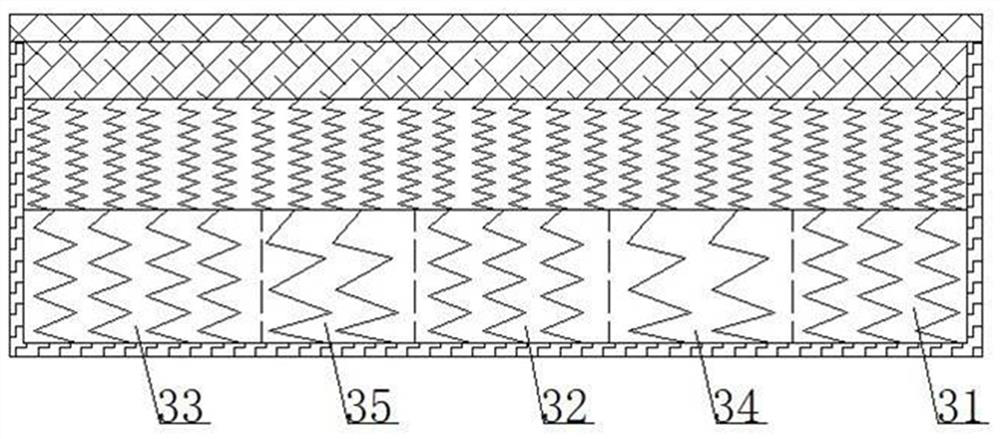

[0047] (1) Select suitable springs to make hard spring layer, soft spring layer, first buffer spring layer and second buffer spring layer;

[0048] (2) Preparation of blasting cotton: polyurethane is used as the main component, combined with functional materials and foamed in the blaster;

[0049]Wherein, the functional material used is one or more combinations of bamboo charcoal, graphene, tencel, silica gel, latex, polyethylene, mint, lavender, pine and cypress, and sandalwood.

[0050] The functional material used may also be a hydrogen peroxide and polyvinylpyrrolidone complex.

[0051] (3) The hard spring layer, the first buffer spring layer and the blasting cotton layer are laid in sequence, and the layers are fixedly connected to make a hard mattress;

[0052] The soft spring layer, the ...

Embodiment 1

[0056] In this embodiment, nanofiltration antibacterial blasting cotton is prepared, and the preparation steps are as follows:

[0057] (1-1) Mix hydrogen peroxide and polyvinylpyrrolidone by weight percentage: 1-10:100-1000 to make a composite solution for later use;

[0058] (1-2) Dissolve linear polyurethane in an organic solvent and prepare a 5-15% solution for later use;

[0059] (1-3) Using an electrospinning machine, the core layer is the solution prepared in step (1-1), and the shell layer is the solution prepared in step (1-2), and the nanofiber is made by electrospinning technology.

[0060] 100-1000 parts of polyurethane, 100-1000 parts of polyvinylpyrrolidone and 1-10 parts of hydrogen peroxide are placed behind the blaster, and saturated water vapor is passed into the blaster for steaming treatment;

[0061] (1-4) Put the nanofibers prepared in the step (1-3) in a blaster and perform blasting treatment to obtain nanofiltration antibacterial blasting cotton.

Embodiment 2

[0063] The raw materials for the preparation of the blasting cotton include the following parts by weight: 65 parts of polyurethane, 3 parts of chitosan, 2 parts of gelatin, 15 parts of silica gel, 4 parts of antibacterial agent, 3 parts of antifungal agent, 8 parts of foaming agent and Water in moderation.

[0064] The preparation of described blasting cotton comprises the steps:

[0065] (2-1) Prepare a 10% gelatin solution with gelatin and pure water at a ratio of 1:9 by mass;

[0066] (2-2) According to the formula, add polyurethane, chitosan, silica gel, antibacterial agent and antifungal agent into the gelatin solution, and dilute with an appropriate amount of water and stir for 2 hours to obtain a mixed solution;

[0067] (2-3) Add foaming agent to the mixed solution obtained in step (2-2), and then introduce it into the blaster, and blast it into blasting cotton with anti-mold and antibacterial type.

[0068] The properties of the prepared nanofiltration antibacteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com