Mortise door lock of adjustable explosion-proof cover

An explosion-proof cover, adjustable technology, applied in the direction of building locks, buildings, building structures, etc., can solve the problems of anti-rotation piece displacement, troublesome and time-consuming, and the direction of the anti-rotation piece lock hole is uncertain, so as to avoid easy misalignment , Easy to adjust, easy and fast unlocking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

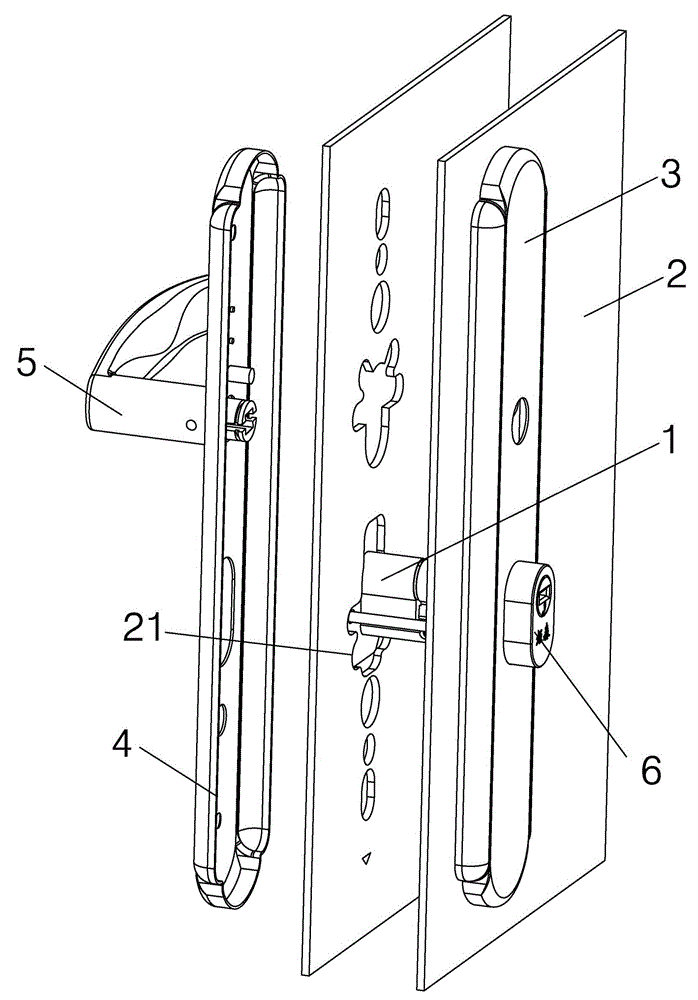

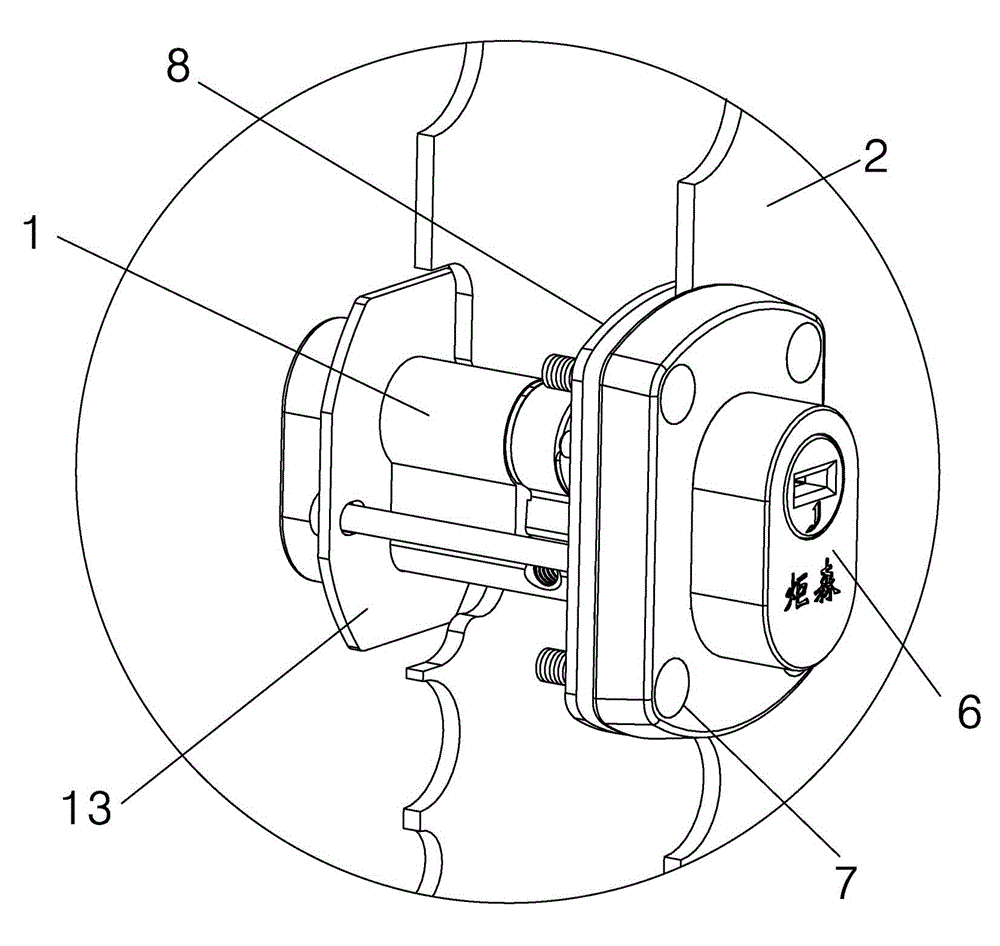

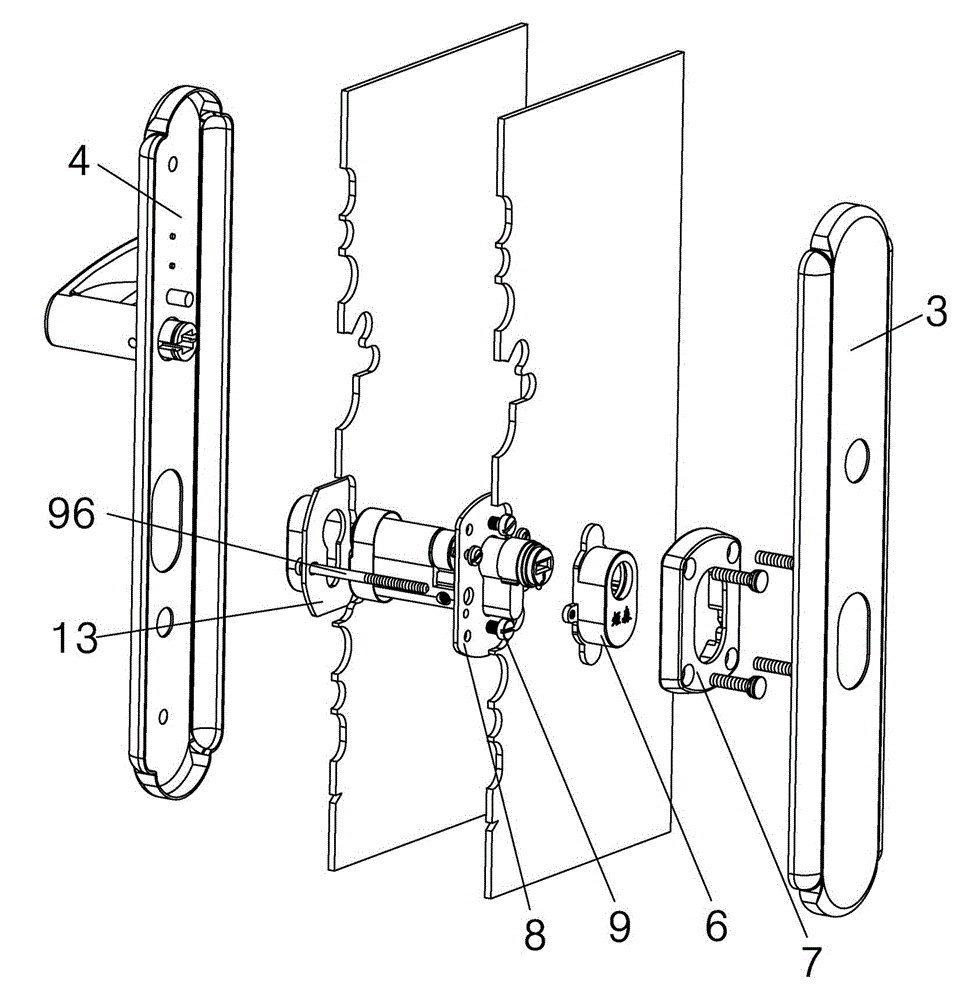

[0027] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A mortise lock with an adjustable explosion-proof cover, which includes a lock cylinder 1 installed inside the door panel, a front panel 3 outside the door panel 2, a rear panel 4 and a handle 5, and is characterized in that the lock cylinder 1 is installed on In the lock hole 21 on the door panel, the outer end of the lock cylinder 1 is covered with an explosion-proof cover 6 and a protective cover 7 in turn, and the protective cover 7 is screwed to the fixing plate 8 arranged on the inner side of the door panel 2 to clamp the door panel between the two. Between the explosion-proof cover 6 and the fixed plate 8, or between the explosion-proof cover 6 and the protective cover 7, a bolt height adjusting device 9 that can adjust the relative distance between the explosion-proof cover 6 and the lock cylinder 1 is provided.

[0028] The bolt height adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com