Carton mark pressing device with cartons pasted accurately

An indentation and precise technology, applied in the field of accurate carton creasing device for gluing, can solve problems such as dislocation of gluing and easy dislocation of carton gluing, so as to prevent quality problems, ensure accuracy, and solve the effect of easy dislocation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

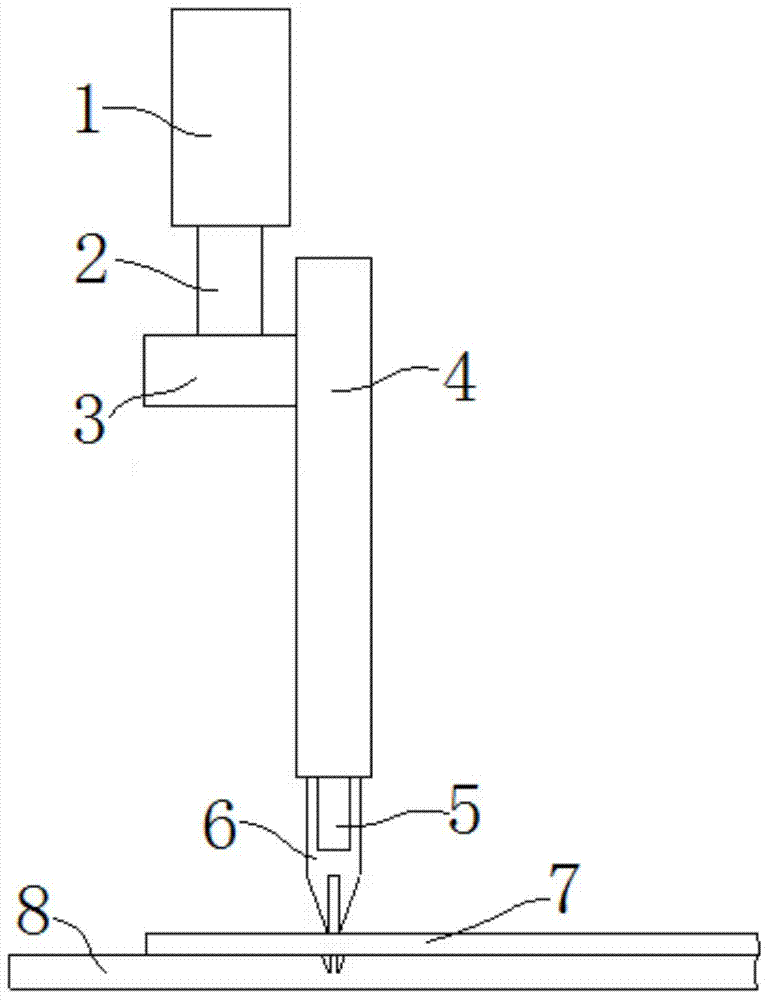

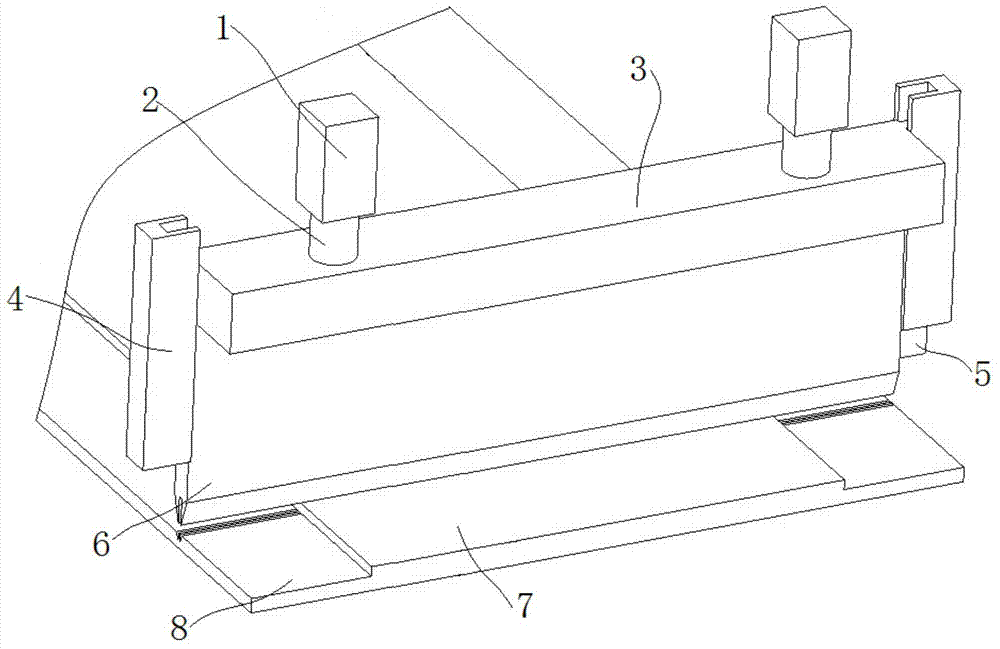

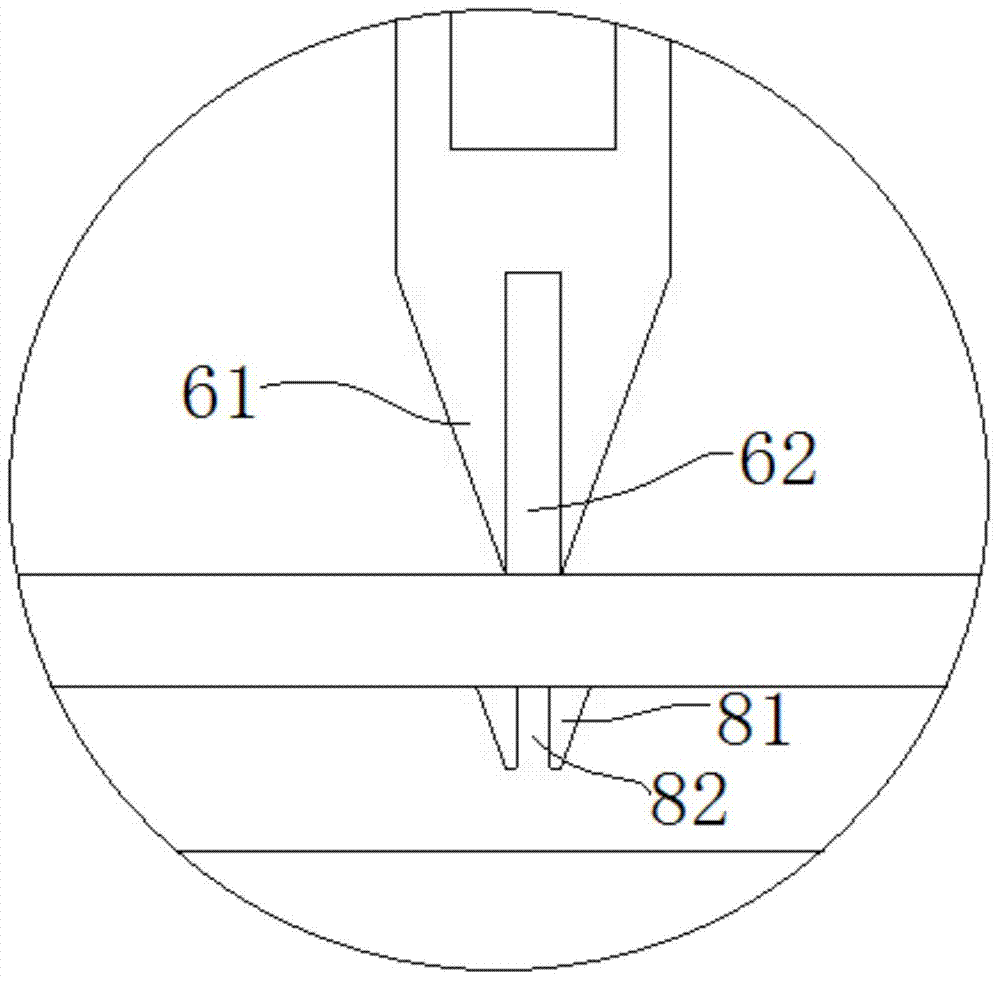

[0024] combine figure 1 with figure 2 , an accurate carton creasing device for pasting boxes in this embodiment, including a cylinder 1, a piston rod 2, a fixed connector 3 and an upper creasing plate 6, and the cylinder 1 is fixedly mounted on the upper creasing plate 6 through the piston rod 2 The fixed connectors 3 on the side are connected; the bottom of the upper indentation plate 6 has two pairs of sharp edges 61 symmetrically arranged. The pair of sharp edges 61 form a cavity 62 with a rectangular cross-sectional shape; a lower indentation plate 8 is provided below the upper indentation plate 6; Groove 81 is arranged, and this groove 81 cooperates with sharp edge 61, and the above-mentioned two grooves 81 form the rib 82 that cross section shape is rectangle, and this rib 82 cooperates with above-mentioned cavity 62 (as image 3 shown); In order to make the position of the upper creasing plate 6 accurate when it rises or falls, and also ensure the accuracy of the cre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com