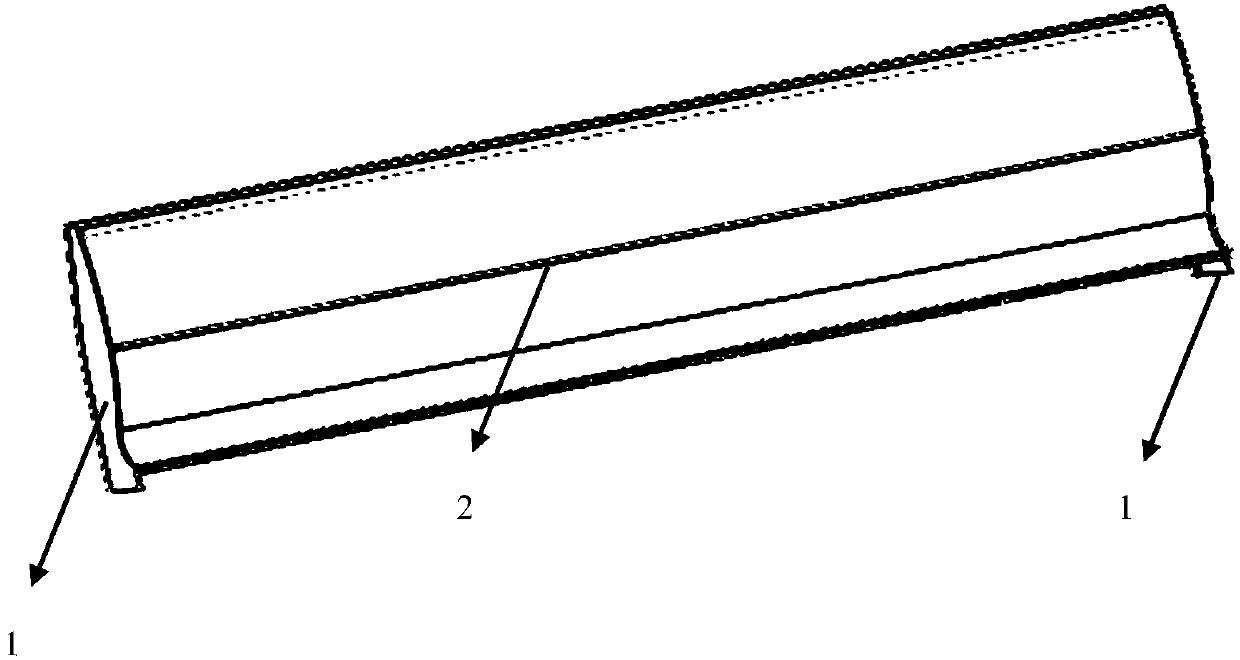

Preparation method of lightweight hollow woven fabric type composite material seat backrest

A seat back and composite material technology, applied in chemical instruments and methods, seats, railway car body parts, etc., can solve the problems of poor mechanical properties, poor comfort, low efficiency, etc., and achieve improved mechanical properties, rapid prototyping, and solution easily misplaced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

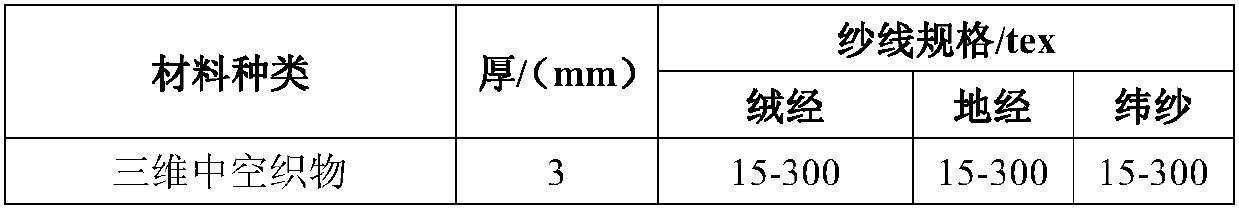

[0032] A method for preparing a lightweight hollow fabric composite seat back comprises the following steps:

[0033] 1) Cleaning the mold: Wipe the dust on the surface of the mold with a brush or a soft rag until there is no dust on the surface of the mold. The cleaning of the mold has a very important impact on the smoothness of the surface of the product and the difficulty of demoulding. After cleaning The mold requires a smooth surface, no dust, no pits, etc.;

[0034] 2) Wipe the surface of the mold evenly with a clean rag dipped in a little NC-55 release agent (Henkel Loctite). During the wiping process, try to make the rag brush evenly in one direction, and there should be no omissions when brushing. The interval between each application is 15 minutes, and the number of application is 5 times;

[0035] 3) Use Taishan glass fiber EW400 fiber cloth to prepare the fiber prefabricated body, and use 3M spray glue to bond the multi-layer fiber cloth into a laminate structure...

Embodiment 2

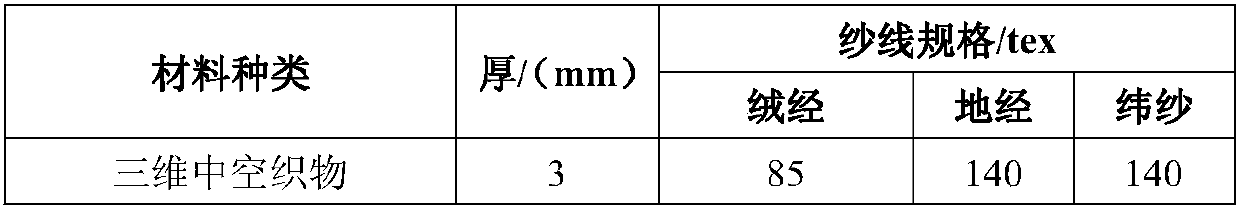

[0046] A method for preparing a lightweight hollow fabric composite seat back comprises the following steps:

[0047] 1) Cleaning the mold: Wipe the dust on the surface of the mold with a brush or a soft rag until there is no dust on the surface of the mold. The cleaning of the mold has a very important impact on the smoothness of the surface of the product and the difficulty of demoulding. After cleaning The mold requires a smooth surface, no dust, no pits, etc.;

[0048]2) Wipe the surface of the mold evenly with a clean rag dipped in a little NC-55 release agent (Henkel Loctite). During the wiping process, try to make the rag brush evenly in one direction, and there should be no omissions when brushing. The interval between each application is 10 minutes, and the number of application is 3 times;

[0049] 3) Use Taishan glass fiber EW400 fiber cloth to prepare the fiber prefabricated body, and use 3M spray glue to bond the multi-layer fiber cloth into a laminate structure,...

Embodiment 3

[0060] It is basically the same as Example 2, except that: after the pouring in step 8), heating at a temperature of 60°C for 8 hours, after the heating process, the system is cooled naturally, and the seat back is obtained after demoulding.

[0061] Through the test, the mechanical properties of the fiber preform are tensile strength 302MPa, test standard GB / T1447-2005; bending strength 310Mpa, test standard GB / T1449-2005; three-dimensional hollow fabric flat compression 3MPa, test standard GB / T1453-2005 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com