Integrated adhesive head of sheet adhesive machine

A mounting head, integrated technology, applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve the problems of increased cost, complex structure, unreasonable structure, etc., and achieves reduced assembly volume, Reasonable structure layout and the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

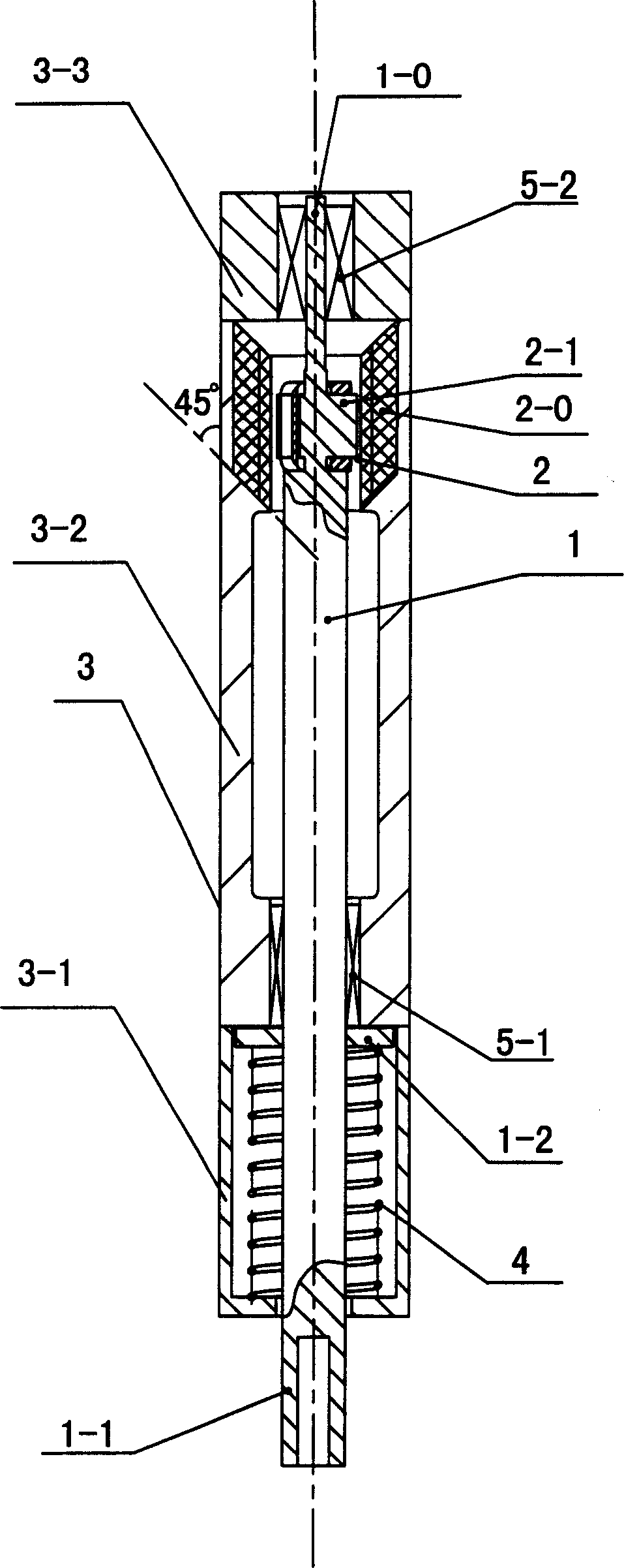

[0024] Such as figure 1 Shown: an integrated placement head of a placement machine of the present invention, the placement head includes a drive motor mounted on the placement head frame, a placement spindle and a suction nozzle, the interior of the placement head frame The main structure is the cylinder wall 3 of the upright multi-corrugated column, and the mounting spindle 1 is located on the central axis of the cylinder wall 3 of the mounting head; the driving motor 2 is a set that can simultaneously drive the mounting spindle 1. The mover 2-1 and the stator 2-0 are composed of a quantitative rotating motion and a quantitative lifting motion. The stator 2-0 of the driving motor 2 is radially symmetrical and fixed in the inner cylinder of the placement head in an axial depth. Correspondingly, on the wall 3, the mover 2-1 of the drive motor is radially symmetrical and fixedly installed on the surface of the mounting spindle 1 in the axial depth; in the axial dimension, the T...

Embodiment 2

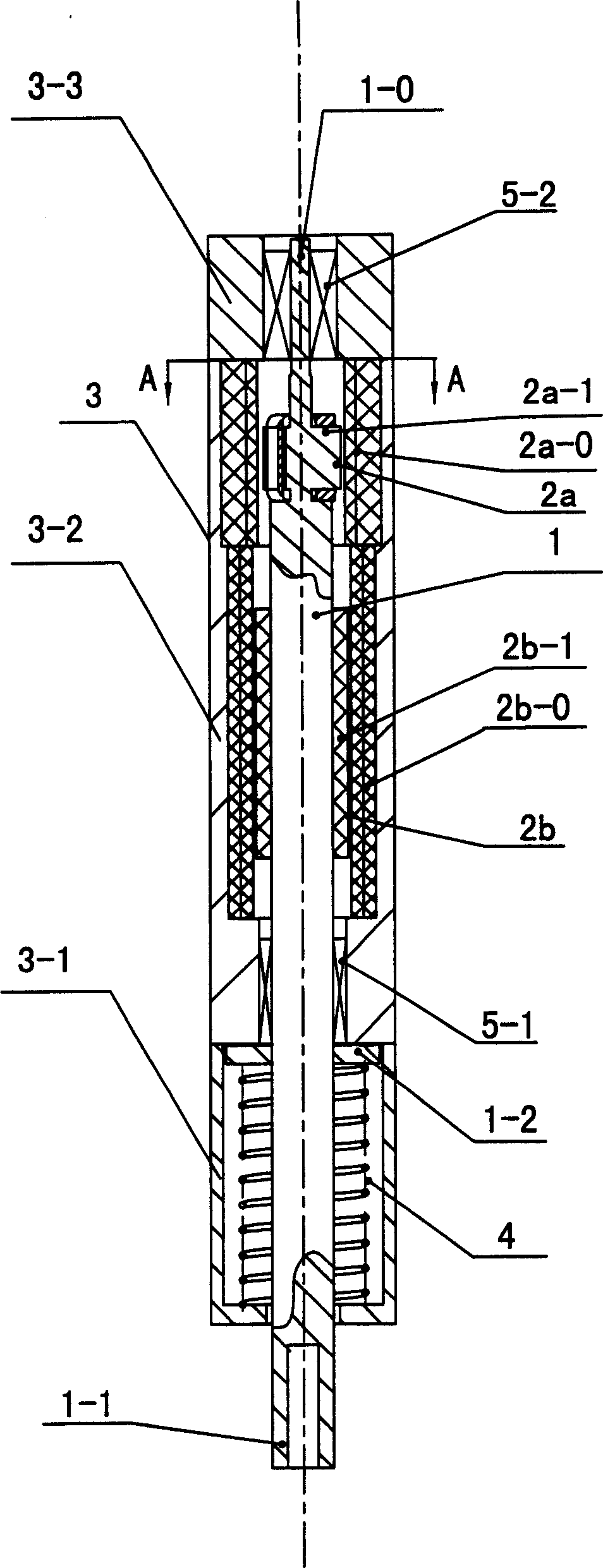

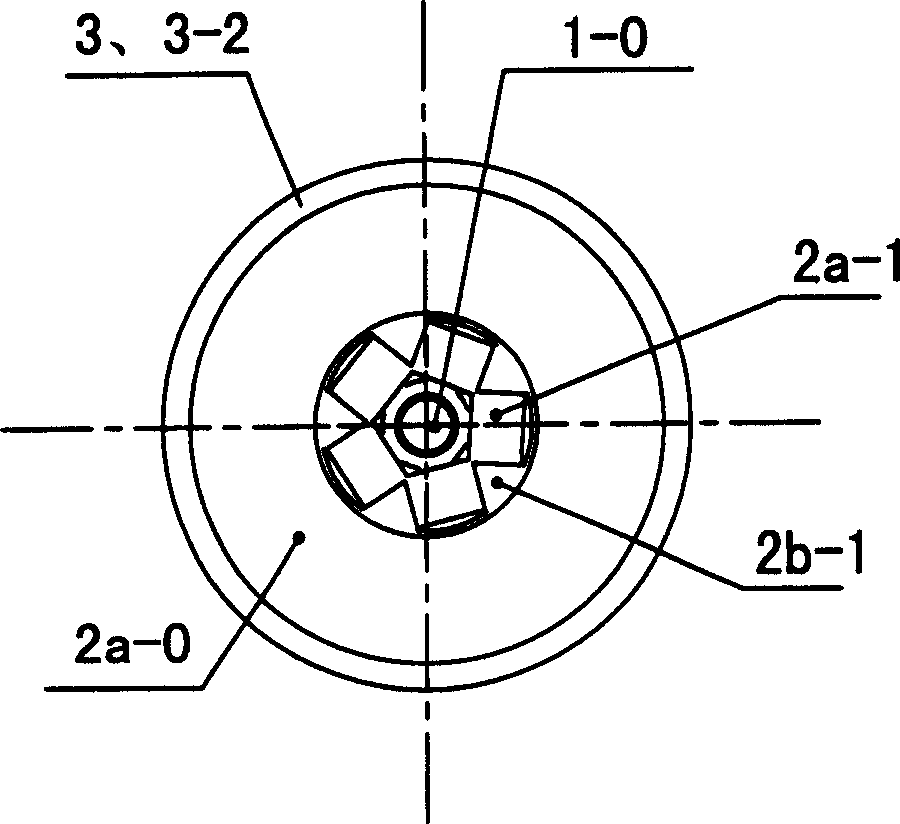

[0030] Such as figure 2Shown: an integrated mounting head of a placement machine of the present invention, the mounting head includes a drive motor mounted on the frame of the mounting head, a mounting spindle and a suction nozzle, and the drive motor is respectively composed of two Set of movers and stators, one set is a stepping rotary motor 2a that drives the mounting spindle to rotate, and the other set is a linear motor 2b that drives the mounting spindle to move up and down.

[0031] The internal main structure of the placement head frame is an upright multi-corrugated column or a cylinder wall 3, and the placement main shaft 1 is on the central axis of the inner cylinder 3 wall of the placement head; the drive motor The stators 2a-0 and 2b-0 of 2a and 2b are radially symmetrical and axially deeply fixed on the inner cylinder wall 3 of the placement head. Correspondingly, the movers of the drive motors 2a and 2b 2a-1, 2b-1 are radially symmetrical and fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com