Fully-automatic dust-free painting line of plastic component

A fully automatic, coating line technology, applied to the surface coating device, coating, spraying device, etc., can solve the problems of low degree of automation and poor coating quality, achieve high degree of automation and reduce manpower Consume, eliminate the effect of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

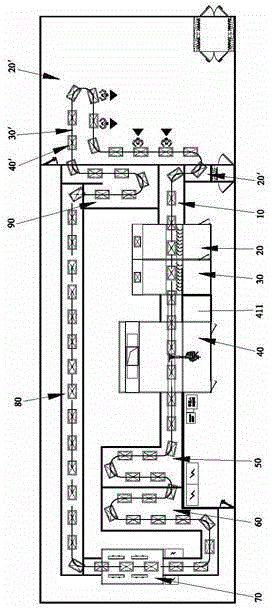

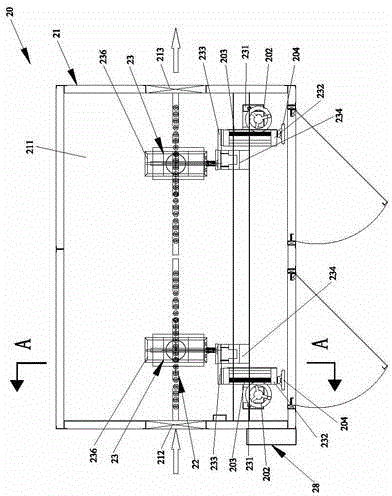

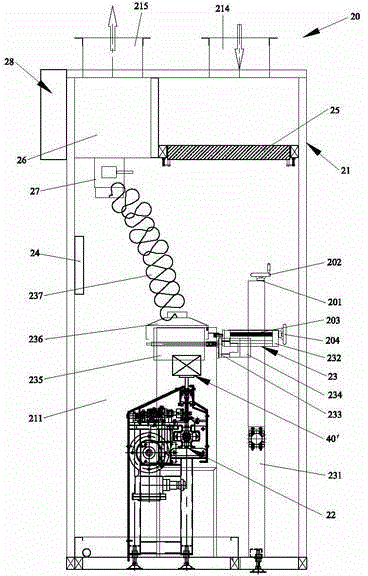

[0078] Please refer to Figure 1 to Figure 9 As shown, it shows the specific structure of the preferred embodiment of the present invention, including preheating furnace 10, first dust removal cabinet 20, second dust removal cabinet 30, spraying room 40, leveling device 50, IR furnace 60, UV light curing machine 70, PU curing furnace 80, cooling device 90 and upper and lower parts area 10'.

[0079] Such as figure 1 As shown, the preheating furnace 10, the first dust removal cabinet 20, the second dust removal cabinet 30, the spraying room 40, the leveling device 50, the IR furnace 60 and the UV light curing machine 70 are connected side by side in sequence and located at the side of the PU curing furnace 80. On the front side, the front side of the input end of the preheating furnace 10 is provided with an air shower 20 ′, the input end of the PU curing furnace 80 is connected to the output end of the UV light curing machine 70 , and the cooling device 90 is located at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com