Single-cylinder type desktop type laser area selecting fusion forming device and control method

A technology of laser selective melting and forming equipment, which is applied in the direction of additive processing, etc., can solve the problems that the structural design does not consider the recovery and cleaning of precious metal powder, is not suitable for fine precious metals, and increases production costs, so as to achieve the promotion of development, volume and The overall weight is reduced and the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

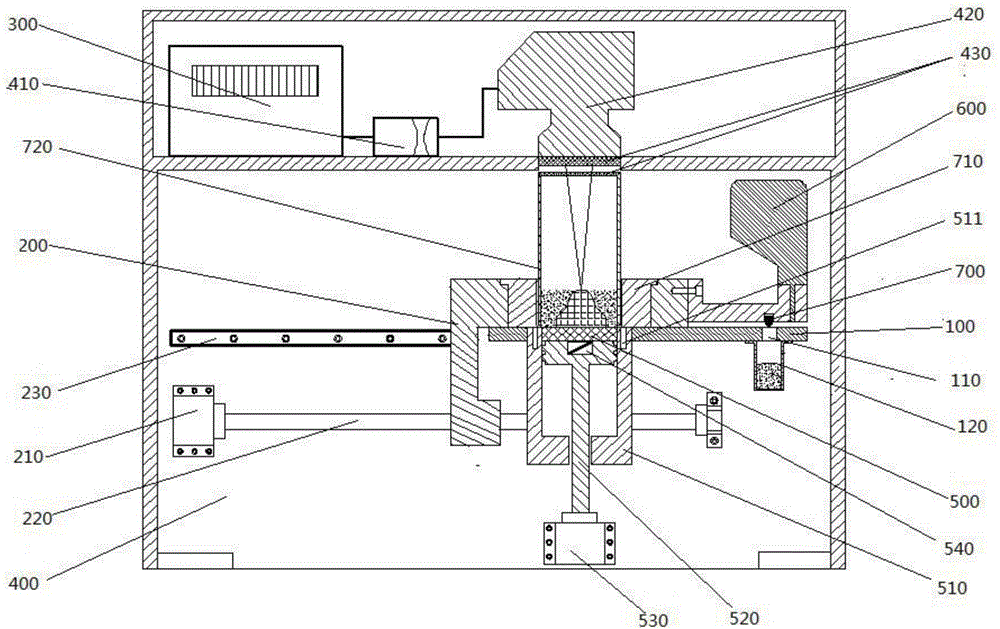

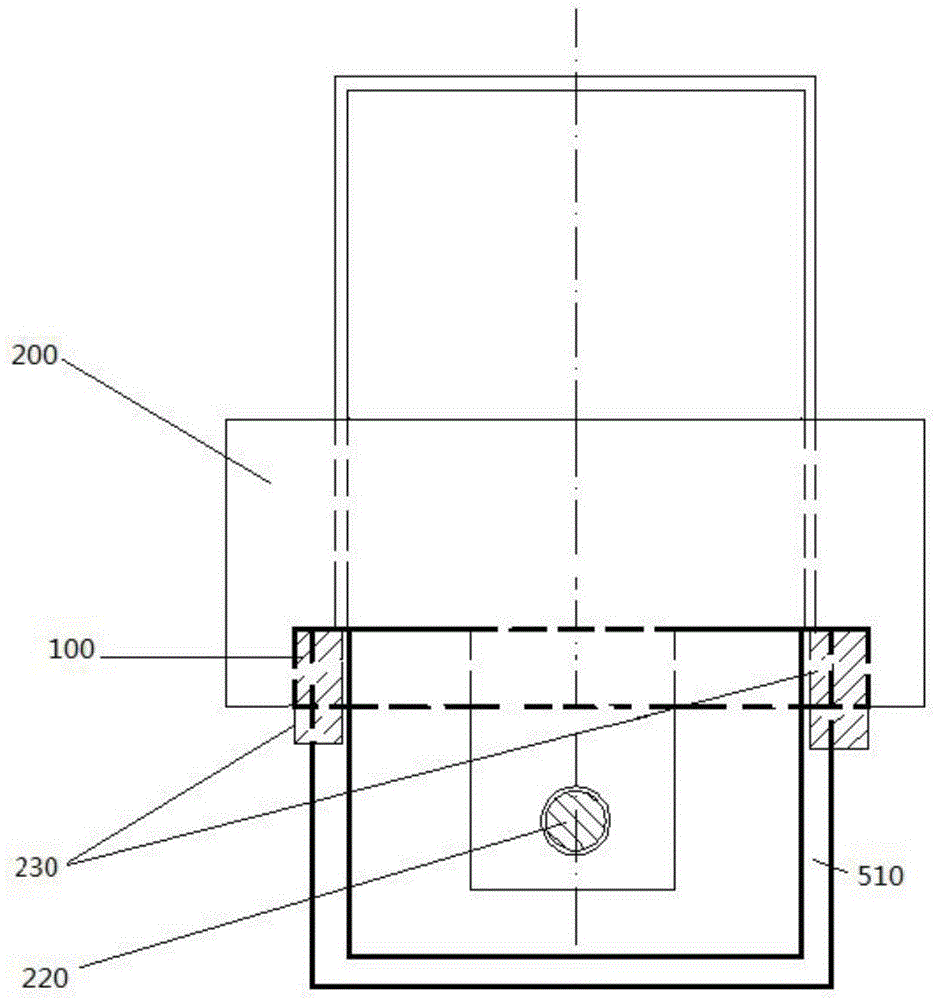

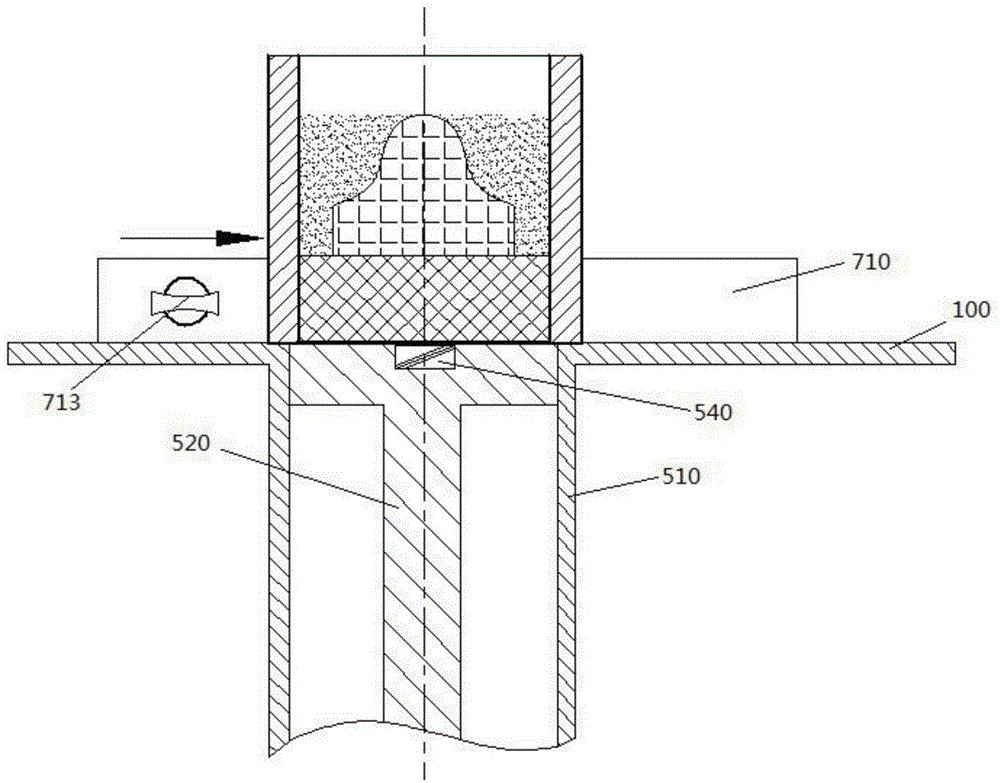

[0043] Such as Figure 1-8 As shown, the single-cylinder desktop laser selective melting molding equipment includes a molding platform 100, a mobile platform 200, a laser 300, an optical transmission device, a molding substrate 500, a powder holding device 600, a powder spreading device 700, a powder taking device, and a protective cover 720 and control system; the molding platform 100 is fixedly arranged in the cavity of the closed molding chamber 400, and the molding platform 100 is provided with a through hole that runs through the entire molding platform 100; the mobile platform 200 is arranged on the molding platform 100, and moves along the The forming platform 100 moves linearly; the powder taking device includes a base 710 and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com