Compound optical sensor and manufacture method and use method thereof

An optical sensor and manufacturing method technology, applied in the field of optical sensors, can solve the problems of increasing process difficulty, reducing production yield, reducing production efficiency, etc., and achieving the effects of reducing manufacturing process difficulty, improving production yield, and saving process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

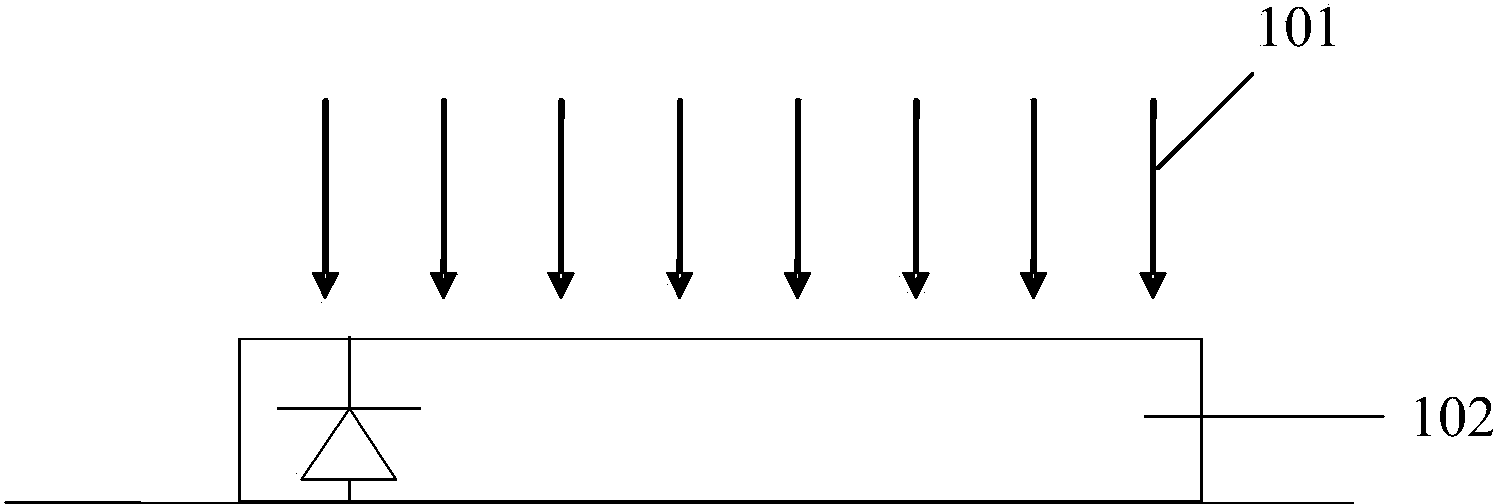

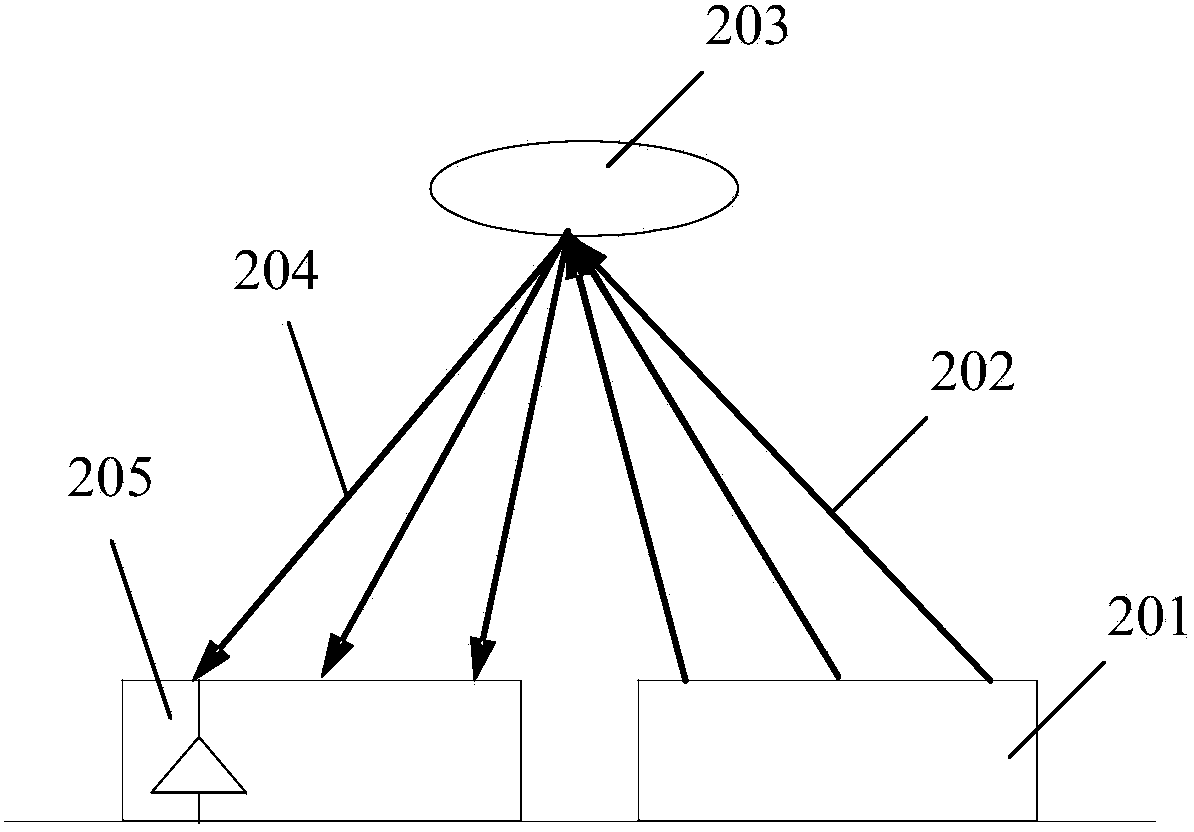

[0074] As mentioned in the background art, in the prior art, the distance sensor, the ambient light sensor and the fingerprint sensor are independently arranged in the electronic product, the structure of the entire sensor system is complicated, occupies a large internal space of the electronic product, and increases the production cost. High, and the production process is complex, the production is difficult, the production efficiency is low, and the application value is low.

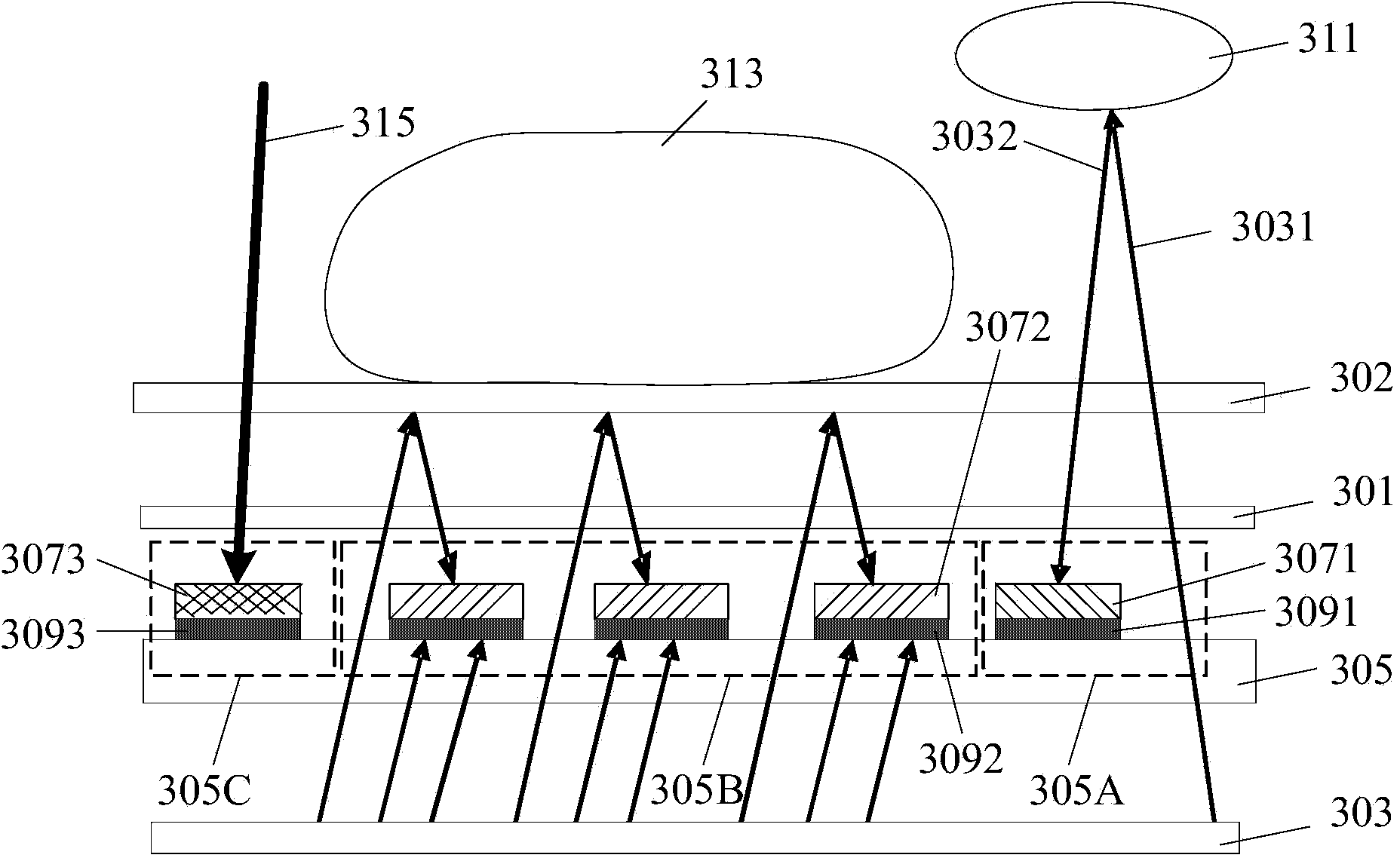

[0075] To this end, the present invention provides a composite optical sensor and a method for making and using the same. The composite optical sensor includes a light source and a transparent substrate, the transparent substrate has opposite first and second surfaces, and the composite optical sensor includes a light source and a transparent substrate. The optical sensor also includes a first pixel array area, a second pixel array area and a third pixel array area, the first pixel array area is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com