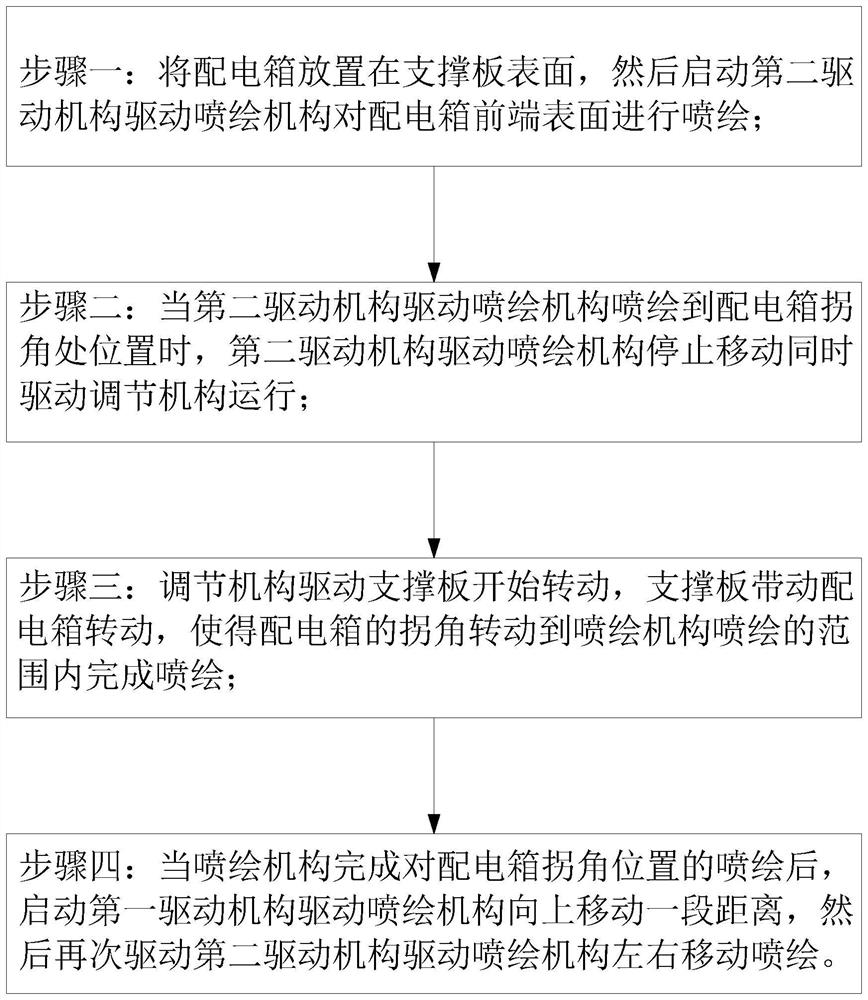

Box-type substation landscape UV painting device and painting method

A box-type substation and inkjet printing technology, which is applied in the field of UV inkjet printing, to achieve the effect of simple operation, convenient use, and improved inkjet printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

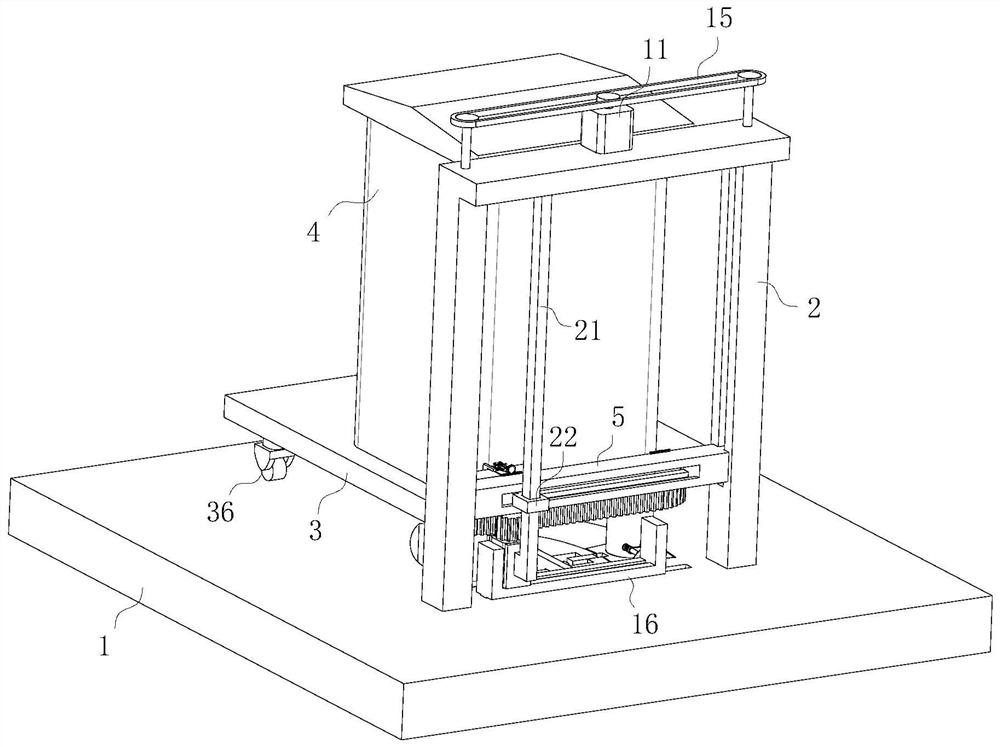

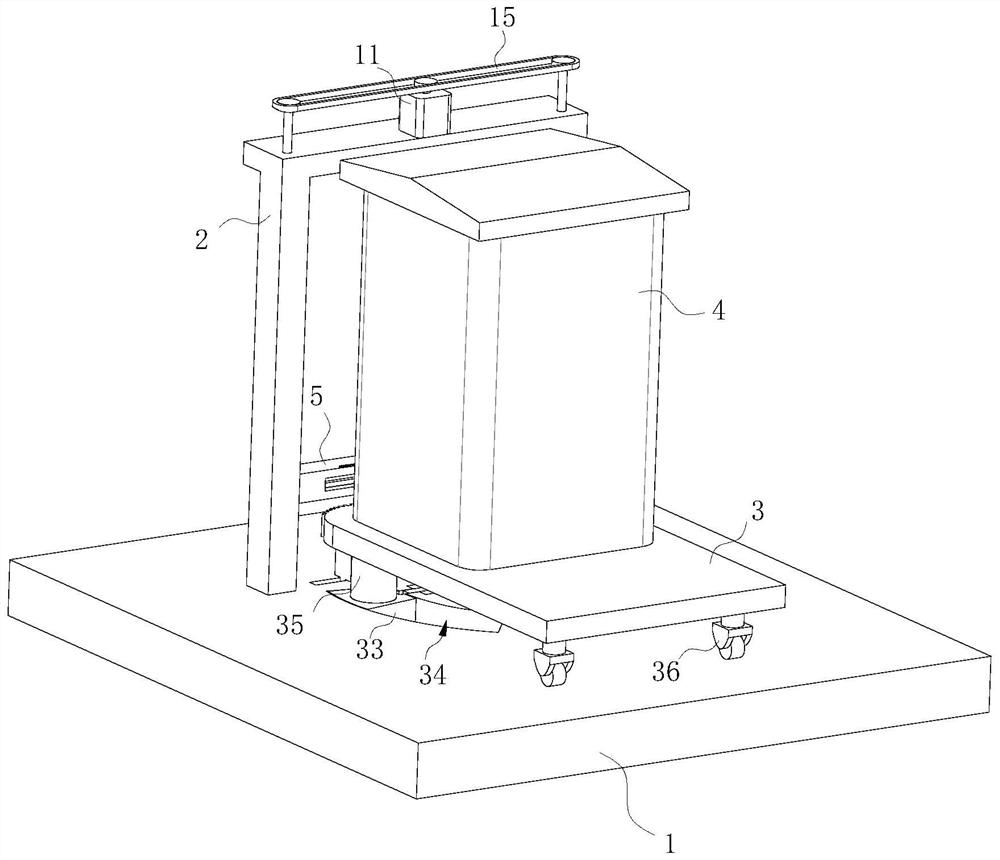

[0034] see Figure 1-11 , The present invention provides a technical solution: a box-type substation landscape UV inkjet printing device and inkjet printing method, comprising a base plate 1, the upper end of the base plate 1 is fixedly connected with a fixing frame 2, and the upper end of the base plate 1 is located at the rear of the fixing frame 2 with a support plate 3, The upper end of the support plate 3 is provided with a substation 4; the fixed frame 2 is provided with an inkjet mechanism, which is used to inkjet the front end surface of the substation 4; the bottom end of the support plate 3 is provided with an adjustment mechanism, which is used to adjust the transformer. The rotation of the electric box 4 is convenient for the inkjet mechanism to inkjet the arc-shaped corner of the substation 4; the surface of the fixing frame 2 is provided with a first driving mechanism, which is used to drive the inkjet mechanism to move up and down for inkjet printing; There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com