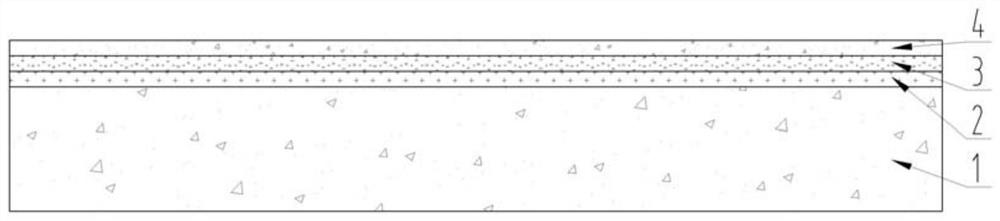

A kind of full-body porcelain tile combined with inkjet effect and preparation method thereof

A technology of porcelain tiles and whole body, applied in the field of architectural ceramic tiles, can solve the problems of not being natural enough, unsightly visual effect, not enough overall body feeling, etc., and achieve the effect of long firing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a whole body porcelain tile combined with an inkjet effect, comprising the following steps:

[0041] (1), according to the above equipped with transparent bottom glaze, standby;

[0042] Equipped with production line glaze line, glaze spraying facilities, ceramic inkjet machine, spare;

[0043] (2), pressing the bottom blank of the ceramic tile and drying it;

[0044] (3), the surface of the bottom base after drying is applied with the above-mentioned transparent bottom glaze;

[0045] (4) Digitally print pre-designed patterns on the surface of the adobe with a transparent bottom glaze, and then print digital protective glaze ink through an inkjet machine;

[0046] (6) It is fired in a kiln with a maximum temperature of 1160°C-1220°C;

[0047] (7) After edging, a whole body porcelain tile with no surface polishing is obtained.

[0048] Preferably, the percentage by weight of the solid content of the digital protective glaze ink in step 4 is 38...

Embodiment 1

[0054] (1), select kaolin, feldspar, quartz and other raw sand materials, and prepare green body porcelain powder according to conventional ceramic technology, and set aside;

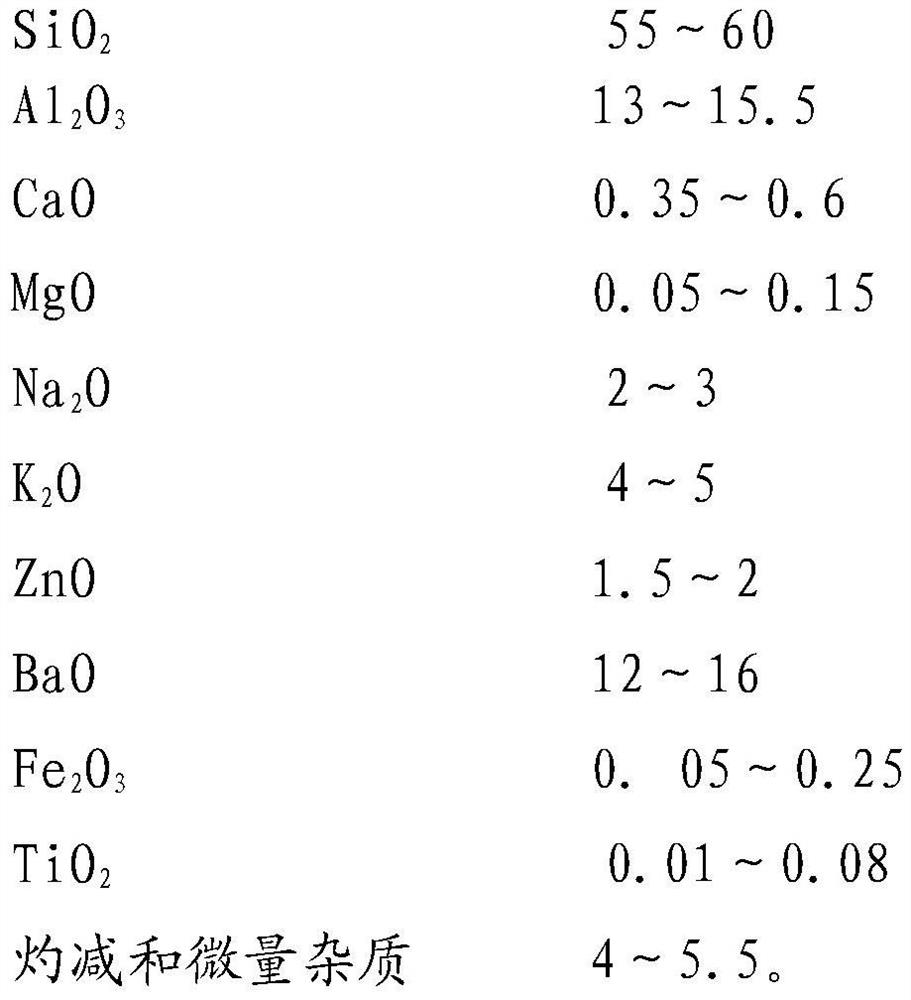

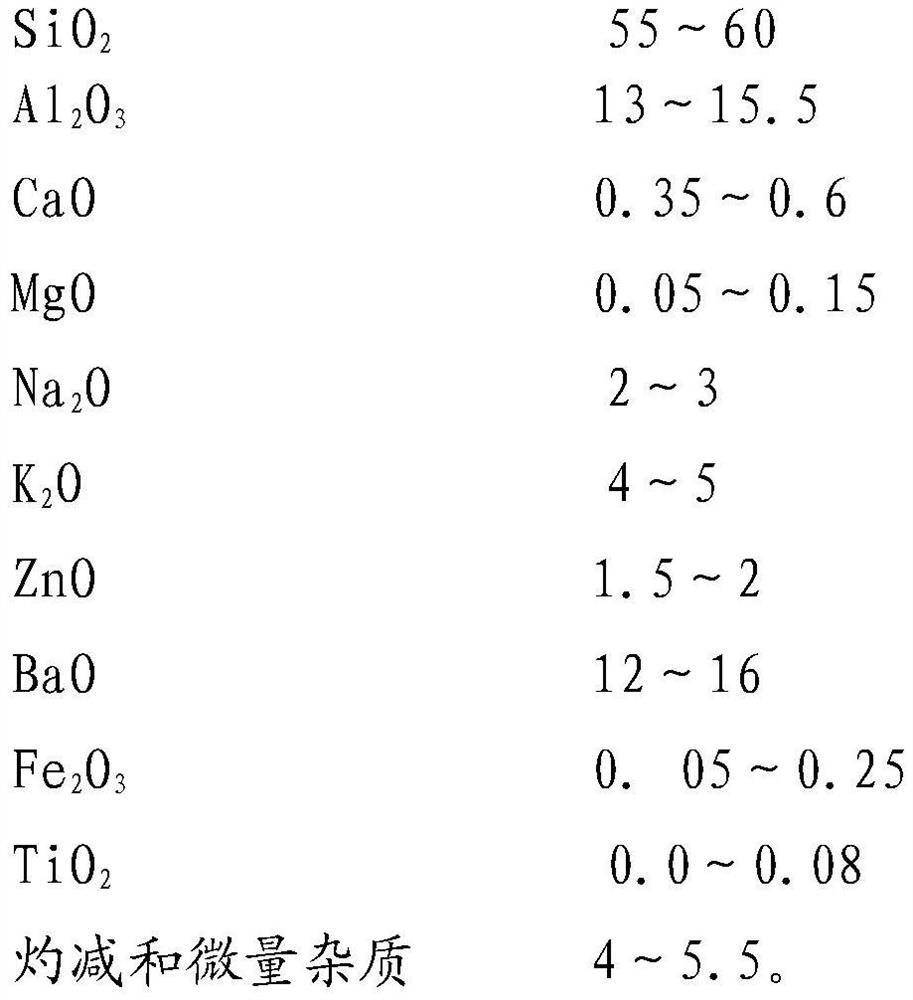

[0055] (2), equipped with transparent bottom glaze, spare;

[0056] According to the formula weight percentage, the composition is 56.7% of silicon dioxide, 14.5% of aluminum oxide, 4.4% of potassium oxide, 2.1% of sodium oxide, 0.4% of calcium oxide, 0.1% of magnesium oxide, 1.7% of zinc oxide, 14.4% of barium oxide, iron oxide 0.2%, titanium dioxide 0.06%, others are burning loss and trace impurities;

[0057] Equipped with a ceramic inkjet machine, and equipped with white, blue, dark brown, dark yellow, black, orange, wrapped red, fine carving, protective glaze ink, protective glaze ink, and spare according to the predetermined channel;

[0058] The solid content of the protective glaze ink chemical composition is 41%, the formula weight percentage is 21.2% of silicon dioxide, and 8.3% of aluminum o...

Embodiment 2

[0066] In step 5 of Example 1, a high-pressure spray cabinet is used to spray transparent protective glaze on the surface of the brick adobe that has been sprayed with a design pattern, and the adobe is sent to a kiln and fired in a kiln with a maximum temperature of 1160°C-1220°C. After edging, a whole body porcelain tile with an unpolished surface is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com