Code spraying system and method for large cylindrical workpiece

A technology of inkjet coding system and cylindrical workpiece, applied in instruments, typewriters, printing and other directions, can solve the problems of low printing position accuracy, high labor intensity of workers, poor consistency of printing effect, etc. Good ink effect and powerful coding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

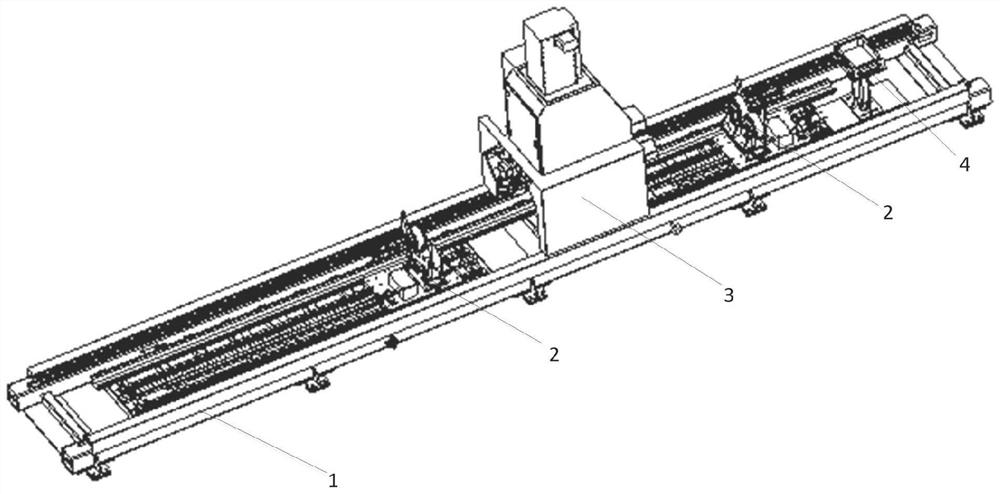

[0051] combine figure 1 , figure 2 , a large cylindrical workpiece coding system and method according to the present embodiment, including a base 1, two supporting weighing mechanisms 2, a coding mechanism 3, an ink basin and a bracket 4, and a control device;

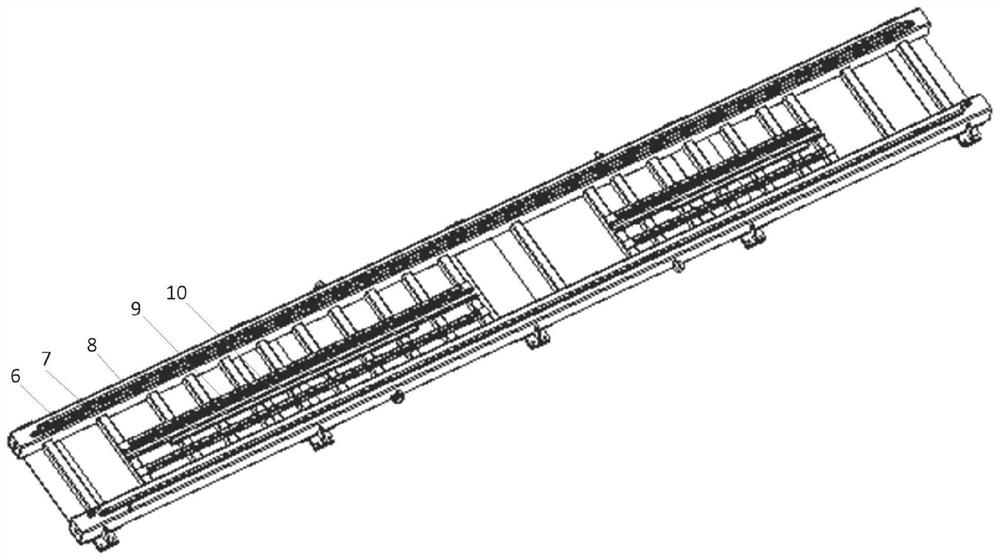

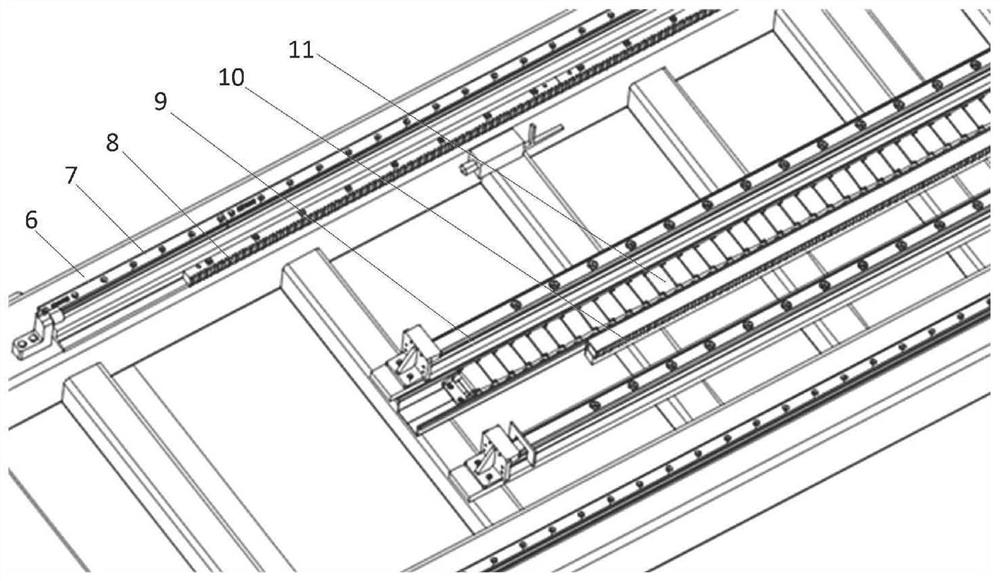

[0052] combine image 3 , the base 1 is used to support the workpiece, including a base support 6, a base edge guide rail 7 arranged on both sides of the base support 6, a base edge rack 8 arranged on one side of the base support 6, and a base rack 8 arranged in the middle of the base support 6 Base internal guide rail 9, base internal rack 10, drag chain and drag chain groove 11;

[0053] combine Figure 4 , the support weighing mechanism 2 is connected with the inner guide rail 9 of the base through the slider 12, and the reduction box and the gear 15 are driven with the rack 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com