Rigid printed circuit board spray printing negative-pressure ink supply pressure control system and method

A pressure control and ink supply technology, applied in printing and other directions, can solve problems such as large ink tube resistance, unsteady ink path pressure in the ink supply system, and undetectable ink supply pressure, so as to ensure negative pressure stability and optimize The effect of inkjet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

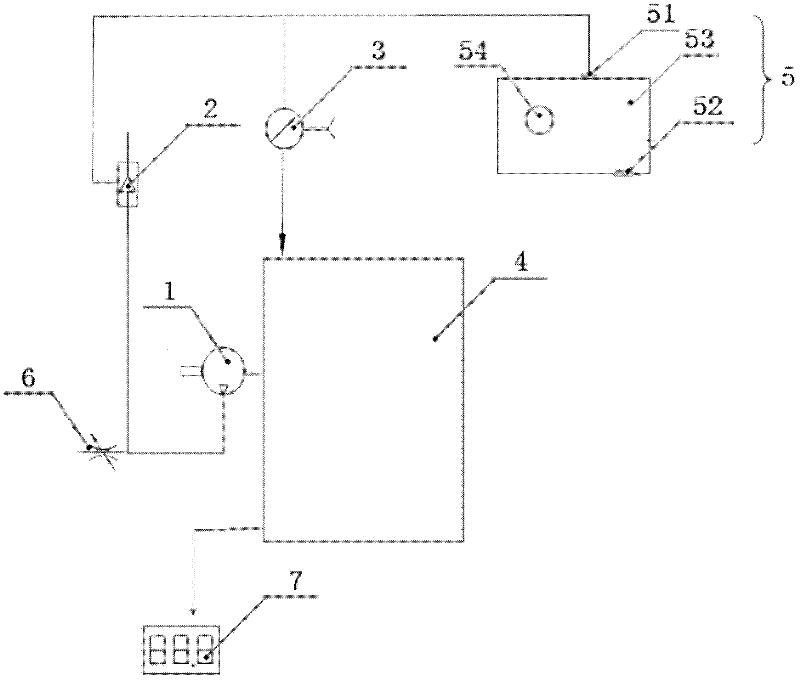

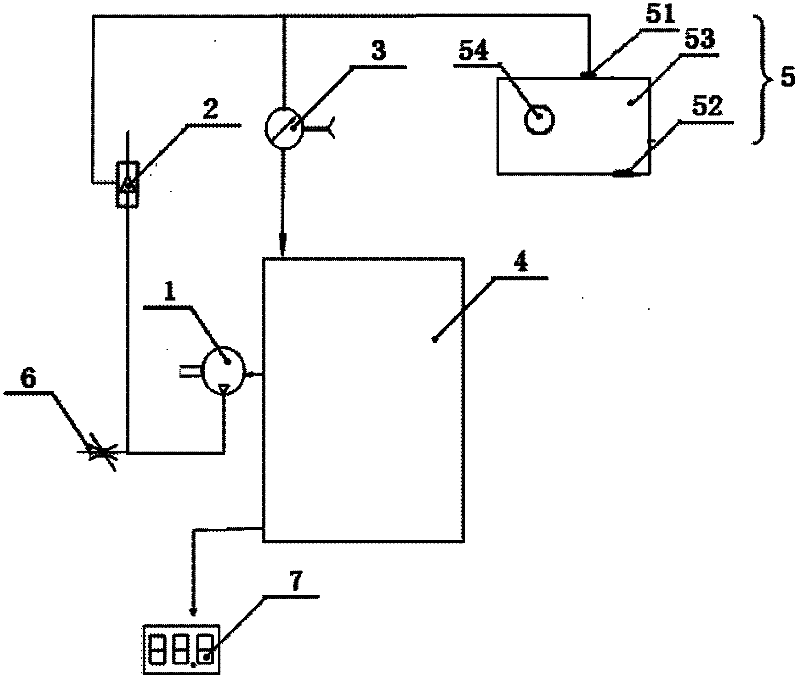

[0021] see figure 1 , the negative pressure ink supply pressure control system of the present invention comprises a vacuum pump 1, a vacuum generator 2, an air pressure sensor 3, a single-chip microcomputer 4 and a nozzle device 5;

[0022] The nozzle device 5 includes a vent 51, an ink ejection port 52, an ink storage box 53 and a float switch 54, the vent 51 is arranged on the top of the ink storage box 53, and the ink ejection port 52 is arranged on the ink storage box 53 At the bottom, the float switch 54 is arranged in the ink storage box 53;

[0023] The suction port of the vacuum pump 1 communicates with the atmosphere, the exhaust port of the vacuum pump 1 is connected to the air supply port of the vacuum generator 2, and the vacuum port of the vacuum generator 2 is connected to the air vent of the nozzle device. 51 connected, the vent 51 is connected with one end of the air pressure sensor 3 at the same time, the other end of the air pressure sensor 3 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com